High-efficiency drum

A high-efficiency drum-drum technology, applied in small raw hide/big raw hide/leather/fur mechanical treatment, raw hide/leather/fur manufacturing equipment, small raw hide/big raw hide/leather/fur treatment, etc., can solve the problem of large working resistance , unfavorable efficiency, easy to tear the skin and other problems, to achieve the effect of reducing resistance, preventing tearing, and increasing activity efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

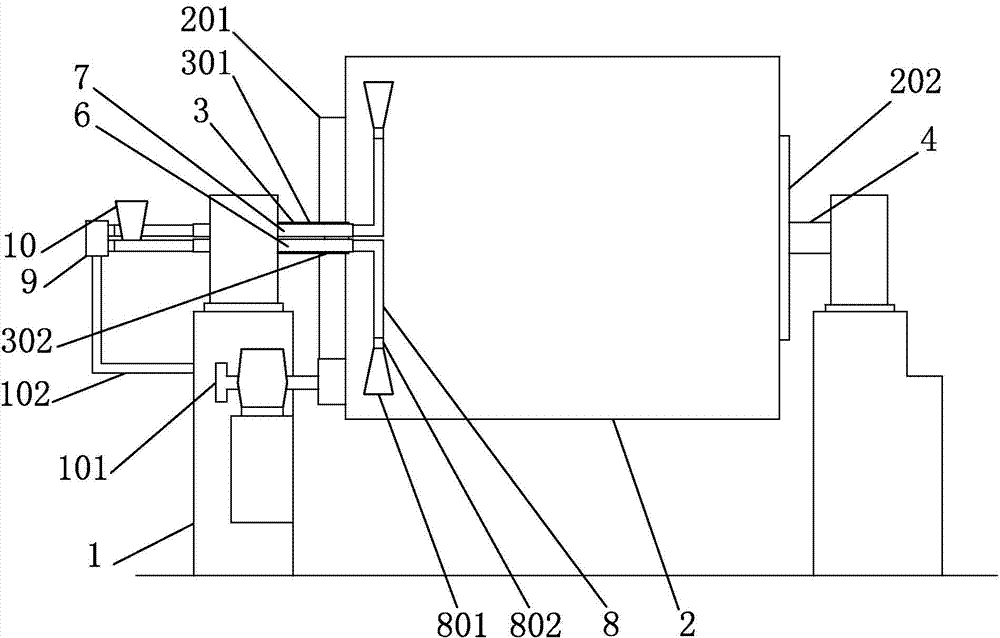

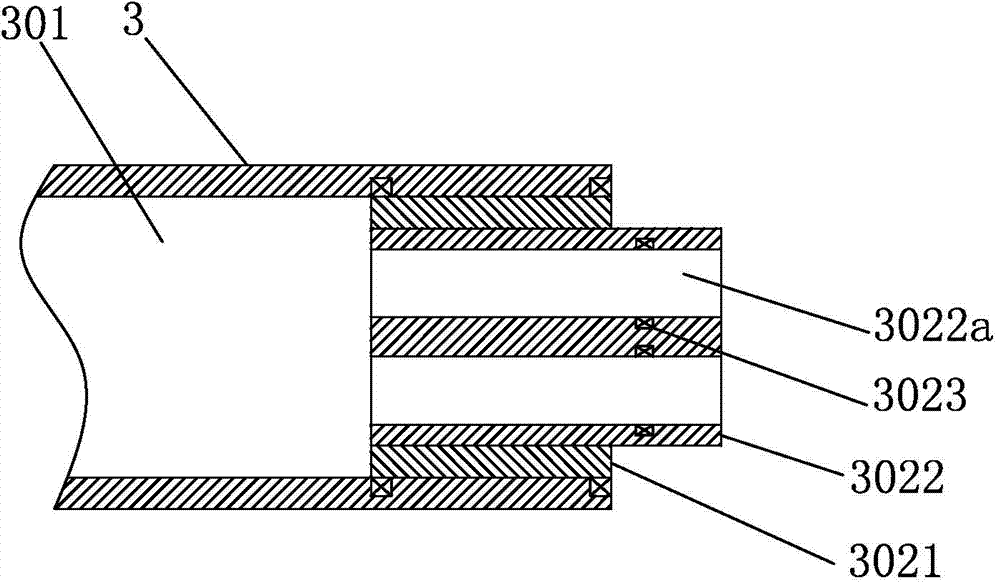

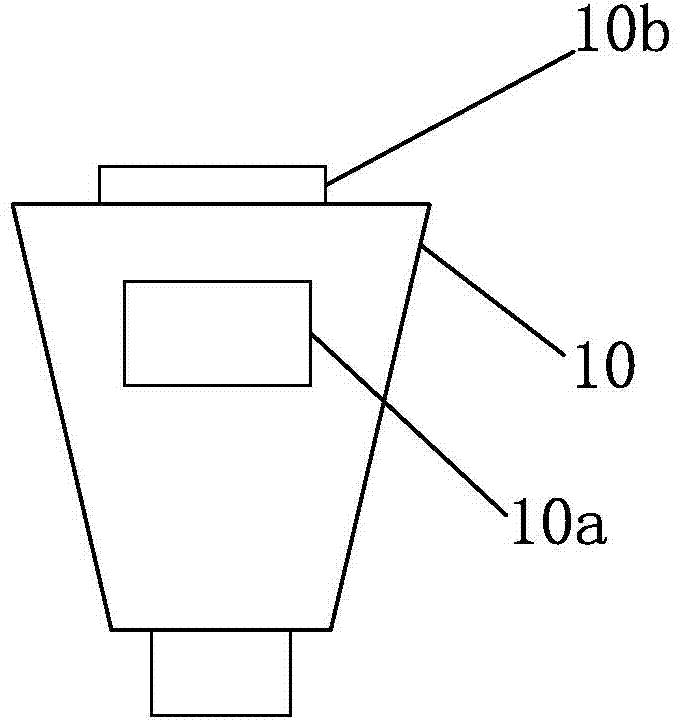

[0022] Such as figure 1 As shown, the present invention comprises a frame 1 and a hollow drum body 2, and the two ends of the drum body are respectively provided with a large gear 201 and a counter plate 202, and the frame is provided with a reduction mechanism 101 connected to the large gear, and the The large gear is connected to the first rotating shaft 3, and the counter plate is connected to the second rotating shaft 4. The two ends of the frame are respectively provided with bearing seats 5, and the first rotating shaft and the second rotating shaft are respectively connected to the bearing seats. It is characterized in that: A through hole 301 is provided along the axis in the first rotating shaft, and one end of the first rotating shaft connected to the large gear communicates with the inner chamber of the drum. The thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com