A joist

A joist and steel frame technology, applied in the direction of joists, girders, truss beams, etc., can solve the problems of heightened floor slab thickness and strength, low safety and reliability, and insufficient strength, so as to improve strength, increase construction speed and Safety and reliability, rapid effect of floor splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

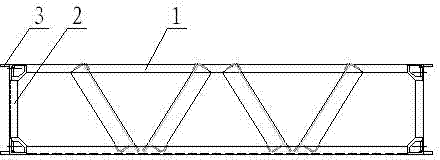

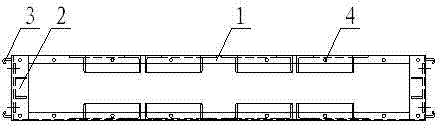

[0013] like figure 1 , figure 2 As shown, a joist 1 is box-shaped or channel-shaped and welded by steel plates or channel steels. When using channel steel to make, the opening of channel steel should be downward, and its bottom is upward, and be drilled with connection hole 4, the size and position of described connection hole 4 should match with the steel frame of the floor slab on joist 1 top, with It facilitates the connection and assembly of the floor slab and the joist 1. The joists 1 can be bolted or welded under the steel frame of the floor slab. When the floors are spliced together, the length of the joist 1 should be designed as the sum of the widths of the two floors, so that the two floors can be combined into a whole, the strength of the connection between the floors can be improved, and the splicing of the floors can be faster, safer and more reliable.

[0014] Both ends of the joist 1 are provided with end plates 2, and the end plates 2 are provided with co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com