Drilling-free cement injecting device for horizontal well

A technology for cement installations and horizontal wells, applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., which can solve the problems of failure to meet and meet the requirements of cementing production operations, restricting the use value, and easy damage Casing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

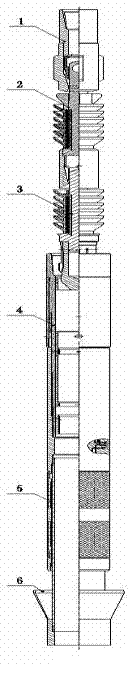

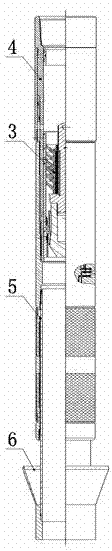

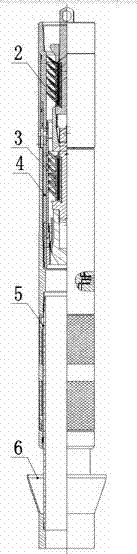

[0034] In order to further disclose the technical solutions of the present invention, the following will be described in detail through implementation cases in conjunction with the drawings of the description:

[0035]A drilling-free cementing device for horizontal wells, including a drill-free device without inner pipe 4, a first-stage switch sliding sleeve rubber plug 3, a second-stage replacement bumper rubber plug 2, a self-locking and retractable overshot 1, and an extended double-stage Parallel seat seal casing outer packer 5 and cement umbrella 6; characterized in that: the connection relationship of the horizontal well drilling-free cement injection device is connected according to the cementing program: when the pre-fluid is injected to clean the well wall, there is cement The extended double-stage parallel seat seal outer packer 5 of the umbrella 6 is connected to the non-inner pipe plug-free device 4, and is connected with the cementing string and lowered into the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com