Stove with afterheat utilization function

A stove and function technology, which is applied to the stove field with the function of waste heat utilization, can solve the problems of unfavorable water tank insulation, unfavorable personnel safety, heat energy loss, etc., and achieves the effect of better waste heat utilization, improved detection accuracy, and safety protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

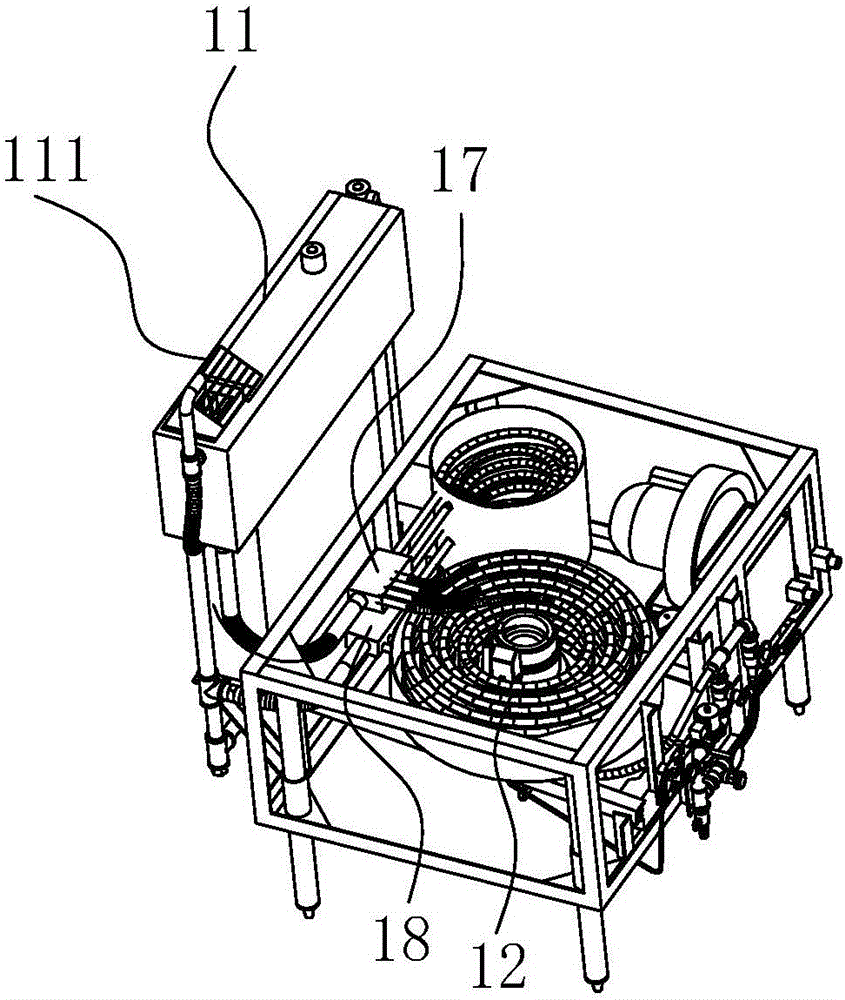

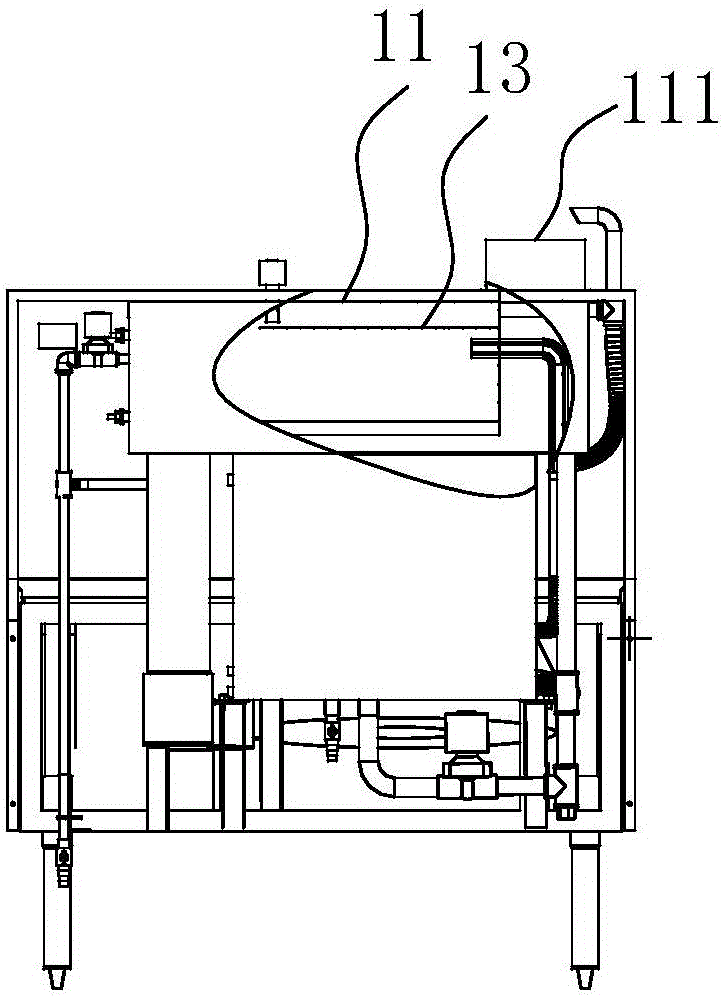

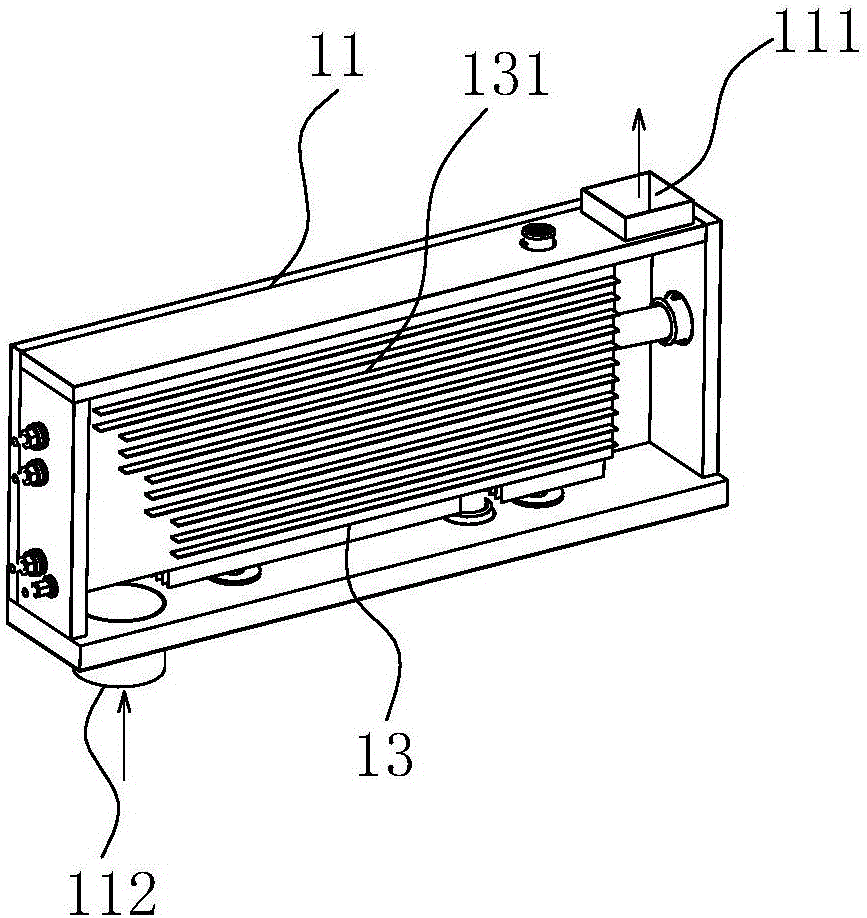

[0031] Now describe in detail the structural features of the present invention in conjunction with the accompanying drawings:

[0032] The stove with waste heat utilization function of the present invention includes a sealed box 11 that communicates with the furnace and allows the flue gas generated in the furnace to pass through. The furnace is provided with a heat exchange tube 12 for absorbing the waste heat of the flue gas. The sealed box 11 is provided with a cold water heating box 13 for absorbing waste heat of flue gas. The surface of the cold water heating box 13 is provided with a heat absorbing sheet 131. The heat exchange tube 12 communicates with the cold water heating box 13. The sealed box 11 There is also a smoke exhaust grid 111 on it. In the present invention, the flue gas generated in the furnace is removed by the flue gas channel formed by the gap between the inner wall of the sealed box 11 and the cold water heating box 13, which greatly prolongs the flow p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com