Lubricating oil replacing device for nuclear power plant

A technology for replacing equipment and lubricating oil, applied in the direction of mechanical equipment, lubricating parts, engine lubrication, etc., can solve the problems of simple structure, shorten the service life, lubricating oil pollution, etc., achieve simple and compact structure, prolong the service life, avoid The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

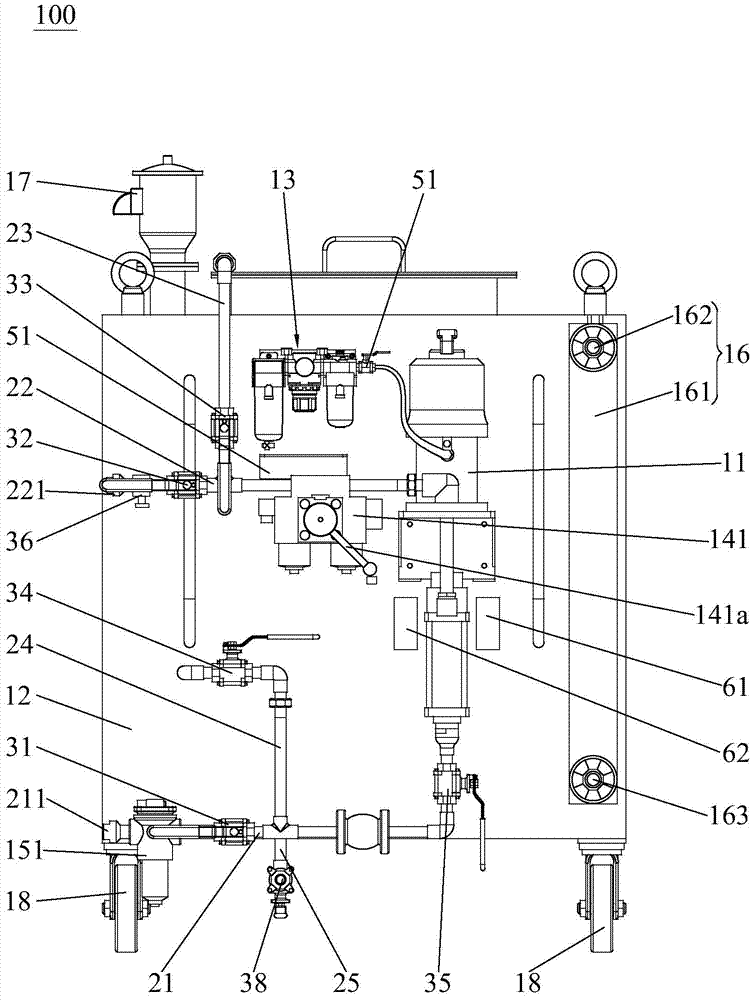

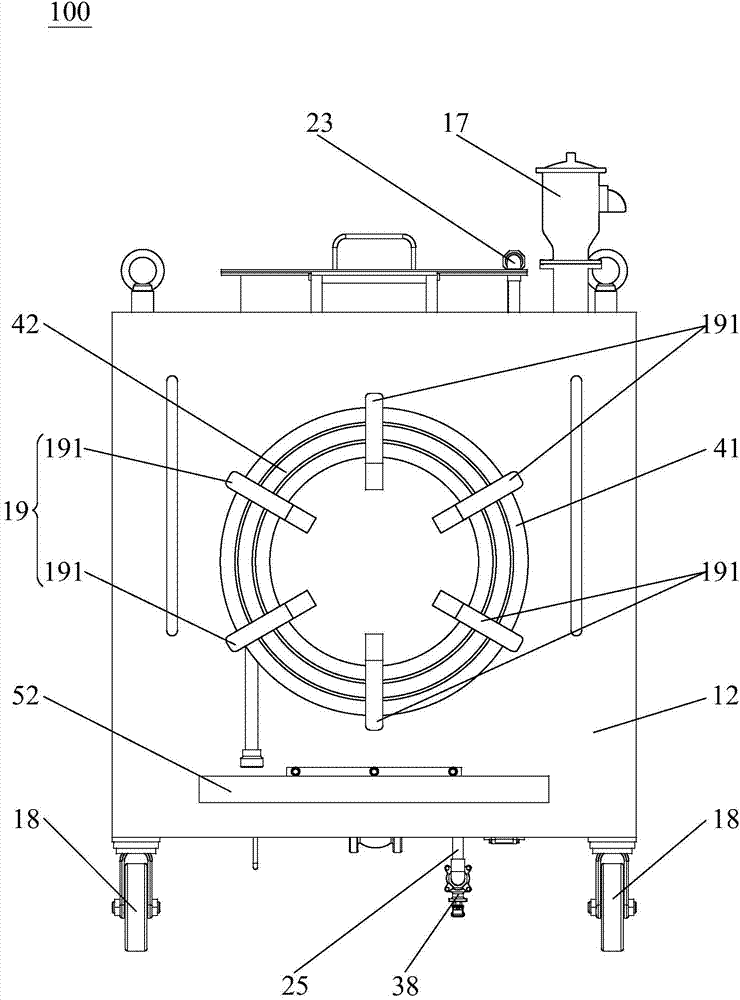

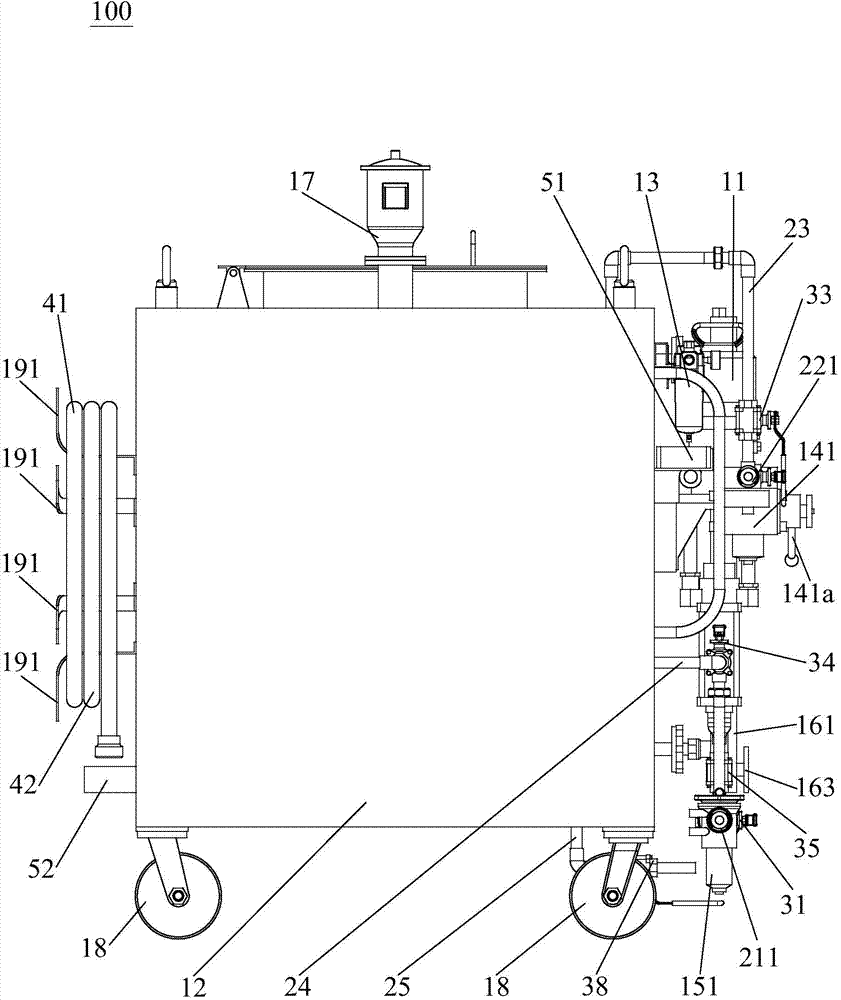

[0026] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

[0027] see Figure 1 to Figure 3 , the lubricating oil replacement equipment 100 for nuclear power of the present invention comprises an automatic oil pump (not marked in the figure), an oil suction pipe 21, an oil supply pipe 22, an oil inlet pipe 23, an oil outlet pipe 24 and an oil storage tank 12 for storing lubricating oil, an oil suction pipe 21 is provided with a first valve 31, the oil supply pipe 22 is provided with a second valve 32, the oil inlet pipe 23 is provided with a third valve 33, and the oil outlet pipe 24 is provided with a fourth valve 34; the oil storage tank 12 is provided with an oil inlet (in the figure not shown) and oil outlet (not shown in the figure), in detail, in the present embodiment, the oil inlet is opened on the top of the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com