Combined energy-saving environment-friendly biomass fuel boiler

A biomass fuel, energy-saving and environment-friendly technology, applied in steam boilers, water-tube steam boilers, combustion chambers, etc., can solve the problems of short service life and inability to adapt to burners, so as to prolong service life, reduce backfire and pyrotechnic reaction channeling and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

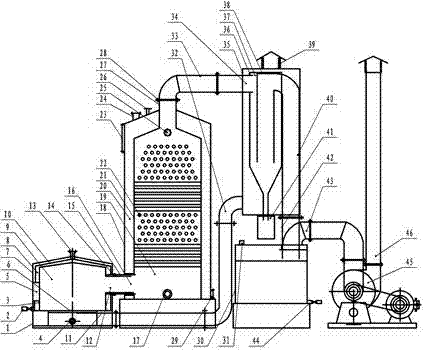

[0016] In order to introduce the present invention in more detail, the present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, a combined energy-saving and environment-friendly biomass fuel boiler includes a combustion device, a boiler device and a waste heat dust removal purifier. The combustion device is a burner with an inner cavity on the furnace wall to recover heat; The boiler device is provided with a plurality of heat-absorbing tubes; the waste heat dust removal purifier is a device that combines waste heat collection and dust removal, and the boiler device is connected to the nozzle 15 of the combustion device through the boiler fire inlet 16, and the boiler device The chimney 27 is connected with the waste heat dust collector through a chimney pipe 33 with a flange 28 .

[0018] The combustion device includes a burner base 1, a boiler burner liner 3, a casing 7, a furnace 9 and a nozzle 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com