Multi-path sharing sealing performance detecting device

A technology of sealing performance and oil circuit, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, and by measuring the acceleration and deceleration rate of fluid, etc., which can solve the problem of increasing the number of pipelines, hidden dangers, safe burial of operators and equipment, etc. problems, to reduce the number of oil circuits, the detection principle is simple, and the effect of preventing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

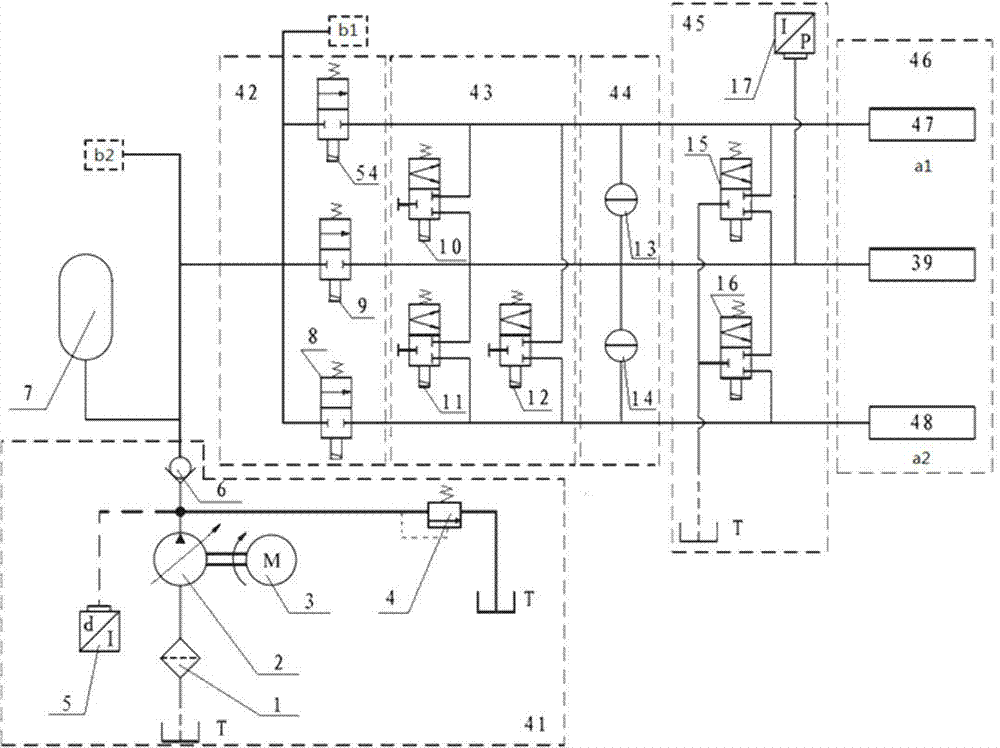

[0038] The present invention is further described below in conjunction with accompanying drawing:

[0039] For multi-channel shared sealing performance detection devices, one or more detection branches with different detection calibers are set up, and one or more detection stations are set for one kind of caliber detection branch, such as Figure 11 , 12 shown. It includes an operating station, and also includes a hydraulic system, a monitoring platform, a safety protection device and a control system. The hydraulic system includes a pressure source module 41 and a number of detection devices connected to the pressure source module 41 that are respectively suitable for different calibers of the test pieces. Branches, each detection branch of a caliber includes one oil circuit for standard parts and several oil circuits for parts to be tested.

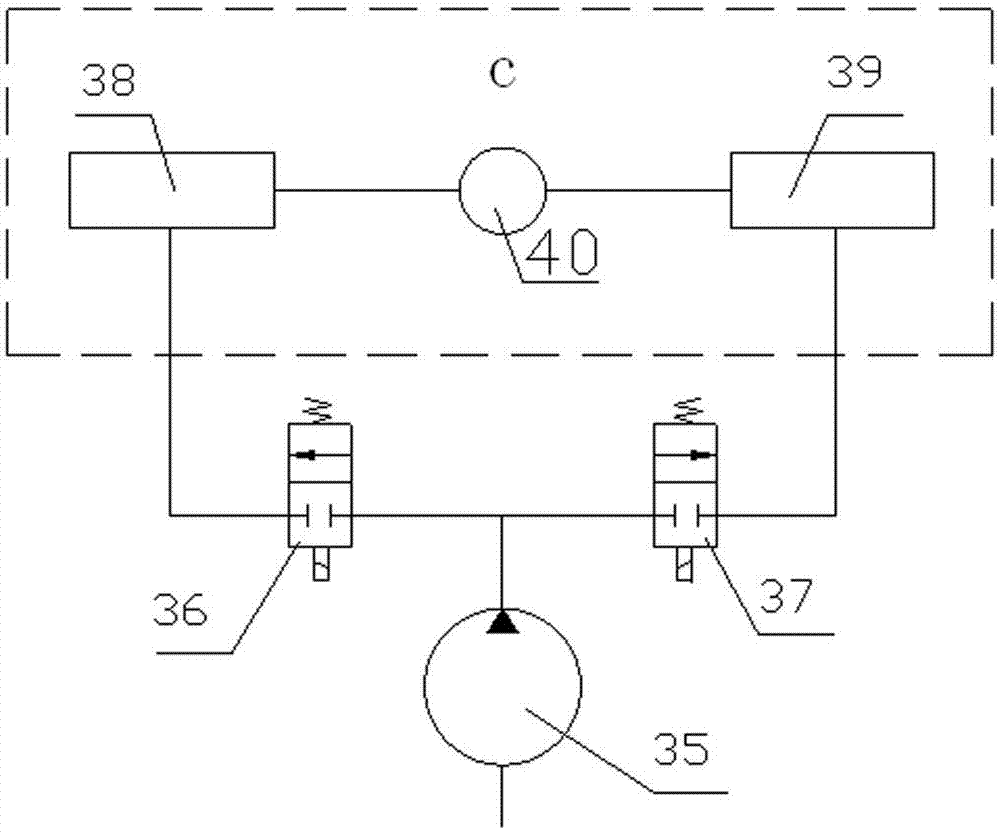

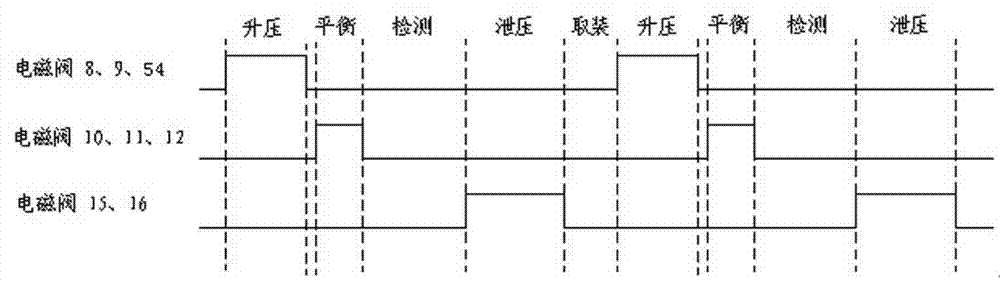

[0040]The hydraulic system of the detection branch of each caliber includes a pressure boosting module 42, a balance module 43, a de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com