Loadable industrial CT (computed tomography) detection device

A detection device, an industrial technology, applied in the field of non-destructive radiation testing and computer tomography, which can solve the problems of limited load bearing capacity, inability to complete real-time CT detection, and the influence of X-ray penetration ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

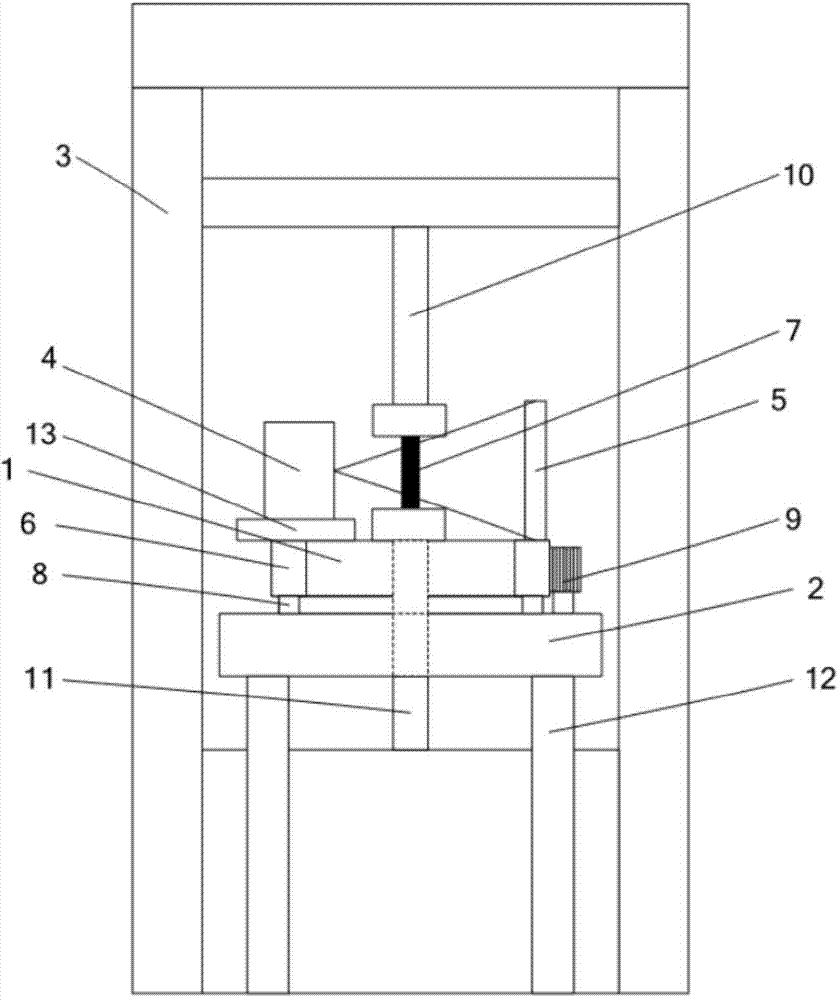

[0020] figure 1 It is a front view of the device of the present invention, as shown in the figure, the device includes a frame 2, a CT scanning device 1 installed on the frame 2, a loading test stand 3, an operation console and an image reconstruction processing device;

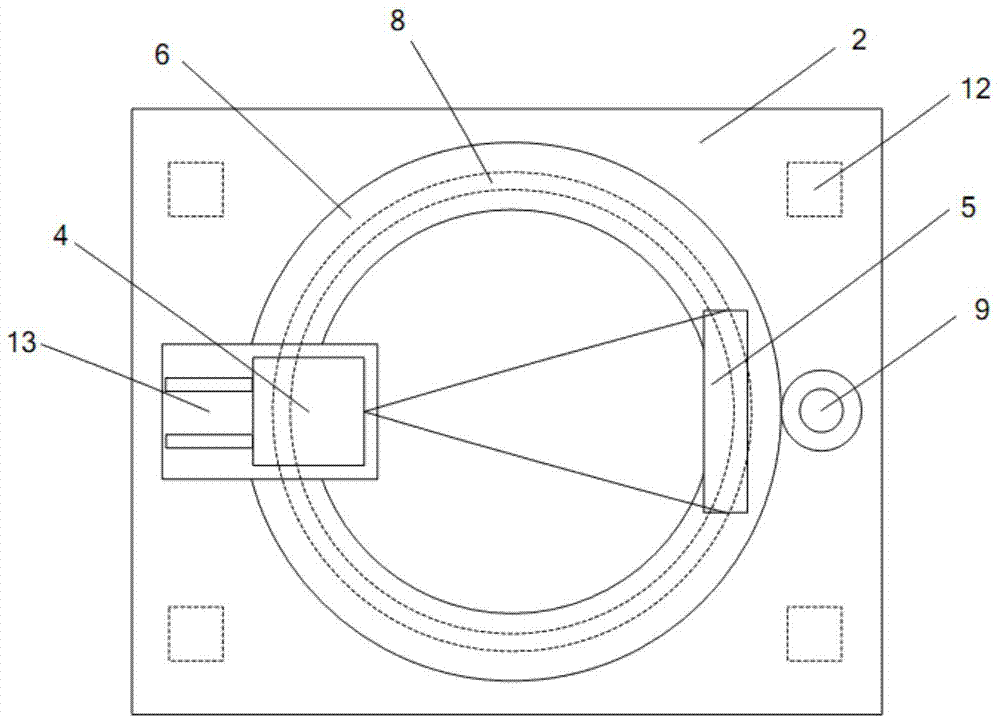

[0021] The CT scanning device 1 is circular. In the CT scanning device, the radiation source 4 and the detector 5 are fixed on a circular ring 6, and the circular ring 6 performs precision rotation on the frame 2. The radiation source 4 can move back and forth along an adjustment mechanism 13 to adjust the distance from the focus of the ray source to the center of the object, such as figure 2 As shown; the loading test bench 3 is used to load the test object with different loads. The loading test bench 3 includes an upper load bar 10 and a lower load bar 11. During CT sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com