A Method of Improving the Accuracy of Measuring the Seebeck Coefficient of Thermoelectric Materials

A technology of thermoelectric materials and coefficients, applied in the measurement of electricity, measurement of electric variables, measurement devices, etc., can solve the problems of thermoelectric conversion efficiency error, inability to meet the quantitative analysis of material physical properties, low measurement accuracy, etc., to ensure accuracy and precision, The method is effective and easy to implement, and the measurement accuracy is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for improving the accuracy of measuring the Seebeck coefficient of thermoelectric materials,

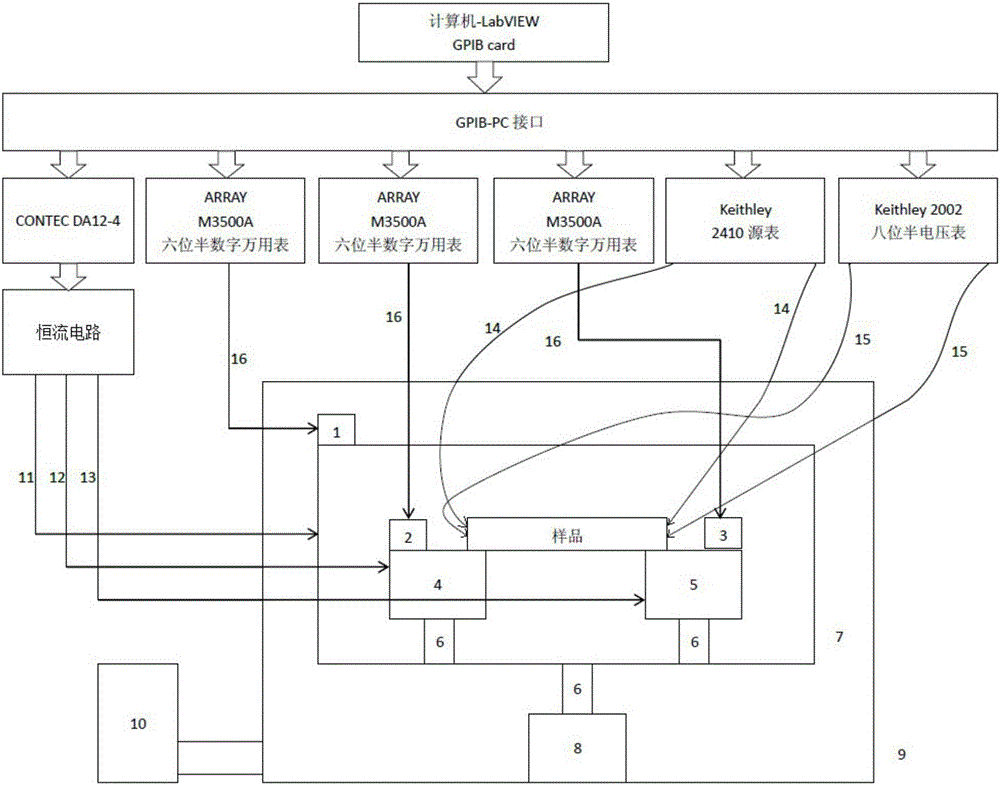

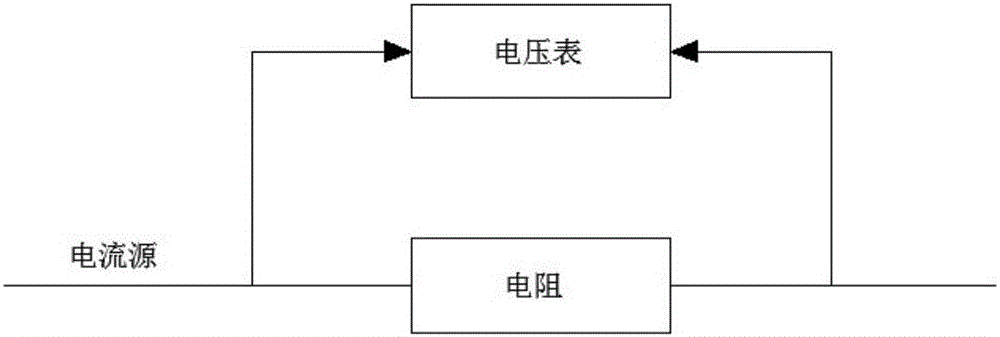

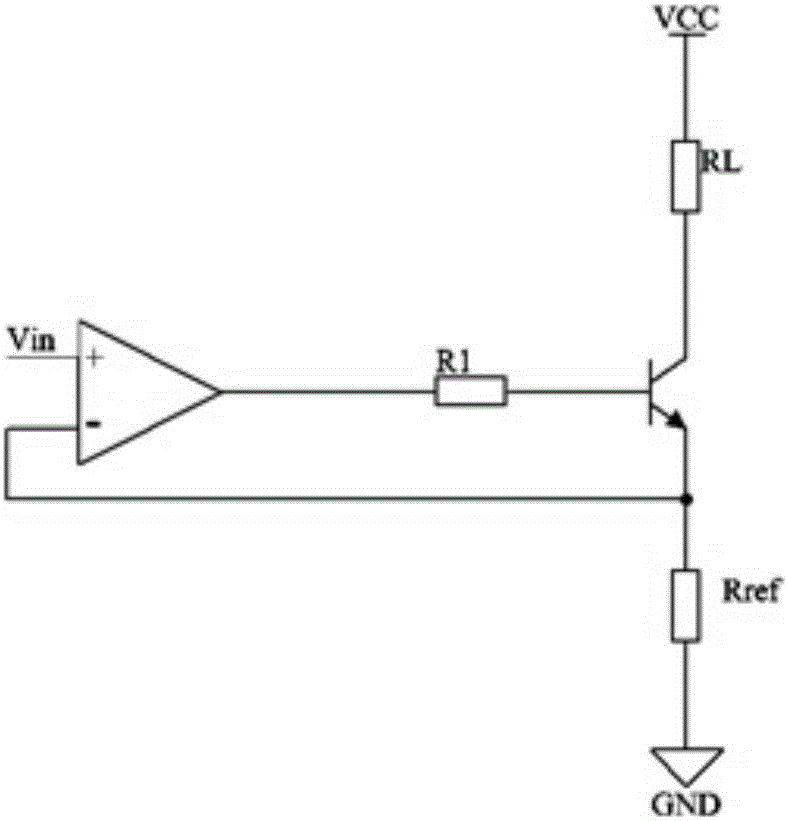

[0050] —Temperature measurement stage: fix three Cernox resistance thermometers on the outer screen 7 of the vacuum, platform A4, and platform B5 where the thermoelectric material is placed, respectively, using thermally conductive glue. These three resistance thermometers are external screen thermometer 1, platform A thermometer 2 and platform B Thermometer 3. The three resistance thermometers are respectively connected to an ARRAY M3500A six-and-a-half-digit multimeter, and the resistance is measured by the four-wire method. The current source provides a controllable constant current for the thermoelectric material. Due to the large internal resistance of the voltmeter, the voltage flowing The current of the meter is ignored, so the reading of the voltmeter divided by the current value is the resistance of the thermoelectric material. Under the condition that the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com