A grid line electrode structure on the back surface of a monocrystalline silicon solar cell and a monocrystalline silicon solar cell

A solar cell and back surface technology, which is applied in the field of solar cells, can solve the problems of large amount of silver paste usage and large backside recombination, and achieve the effects of reducing usage, reducing backside recombination, and improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

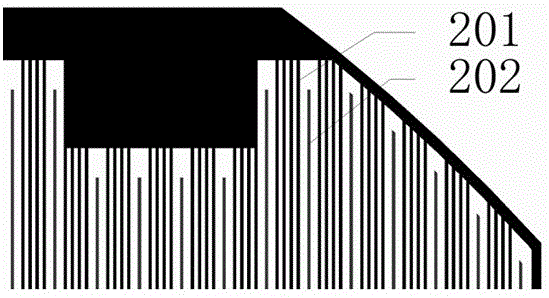

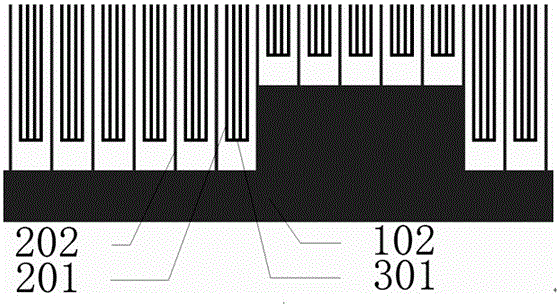

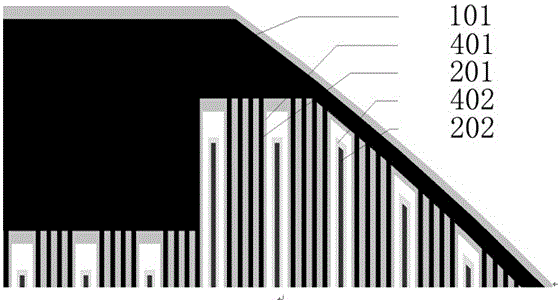

[0030] Such as Figure 1-4 As shown in , the grid line electrode structure on the back surface of the monocrystalline silicon solar cell provided in this embodiment uses a silicon wafer of 156 mm×156 mm with rounded chamfered n-type single crystal silicon wafers, including The p-type emitter 401 and the n-type back field 402 on the surface, the p-type emitter 401 and the n-type back field 402 are alternately distributed and not in contact with each other, and also include the p-type emitter main gate electrode 101, the n-type back field main gate The electrode 102, the p-type emitter fine grid electrode 201 and the n-type back field fine grid electrode 202, wherein the p-type emitter fine grid electrode 201 is located on the p-type emitter 401, and the n-type back field fine grid electrode 202 is located on the n-type back surface On the field 402, the p-type emitter fine grid electrode 201 is connected to the p-type emitter main gate electrode 101, the n-type back field fine ...

Embodiment 2

[0039] Such as Figure 5 As shown in a, the gate line electrode structure on the back surface of the monocrystalline silicon solar cell provided in this embodiment adopts a 4 mm×4 mm square n-type single crystal silicon wafer, including The p-type emitter and the n-type back field, the p-type emitter and the n-type back field are distributed alternately and do not touch each other, and also include the p-type emitter main gate electrode, the n-type back field main gate electrode, the p-type emitter fine The gate electrode and the n-type back field fine grid electrode, wherein the p-type emitter fine grid electrode is located on the p-type emitter, the n-type back field fine grid electrode is located on the n-type back field, and the p-type emitter fine grid electrode is connected to the p-type The emitter main grid electrode is connected, the n-type back field fine grid electrode is connected to the n-type back field main grid electrode, and each p-type emitter fine grid elect...

Embodiment 3

[0051] The difference from Embodiment 1 is that in this implementation, each p-type emitter fine grid electrode is composed of five parallel and evenly distributed thin grids, and the ends of the five parallel and uniformly distributed thin grids are connected by a thin grid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com