Pressing mould for annular refractory brick

A technology for pressing molds and refractory bricks, which is applied in the field of pressing molds, and can solve problems such as damage to punch seats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

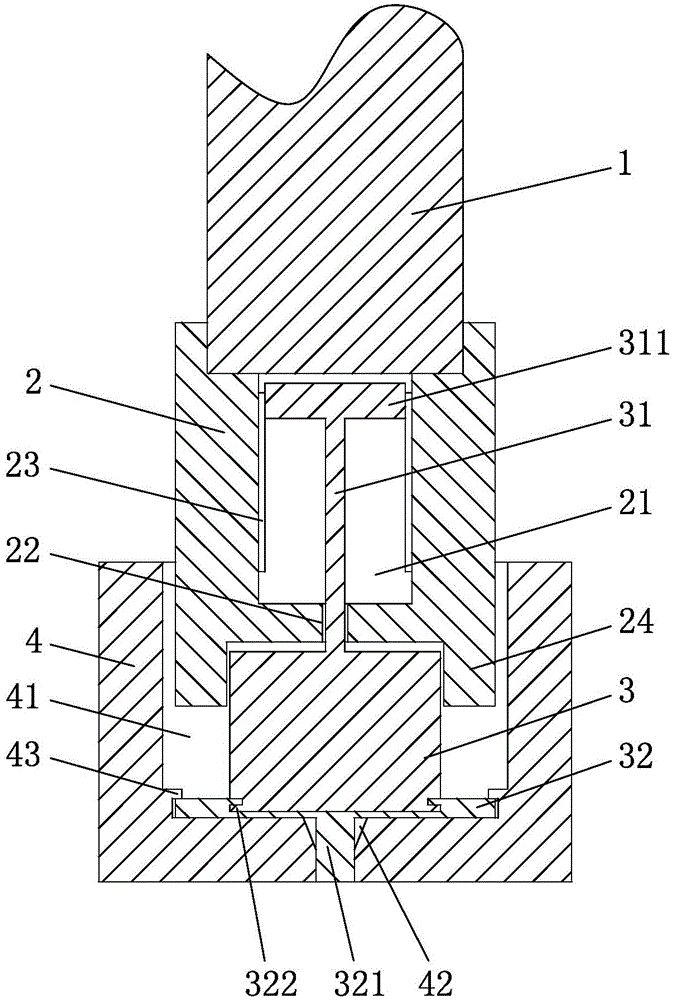

[0015] refer to figure 1 , a pressing mold for annular refractory bricks, including a punch assembly and a punch seat 4, the punch assembly includes an annular ejector pin 1, a stamping head 2, and a spacer block 3 from top to bottom, and the bottom end of the annular ejector pin 1 is The wall is provided with an external thread, and the punching head 2 is provided with a limiting groove 21, and the groove wall at the notch of the limiting groove 21 is provided with an internal thread that cooperates with the external thread, so that the punching head 2 and the annular ejector rod 1 are threaded. connect. The bottom wall of the limiting groove 21 is provided with a limiting hole 22, and the groove wall of the limiting groove 21 is provided with three axially arranged convex ribs 23, and the top surface of the spacer block 3 is provided with a rib that cooperates with the limiting hole 22. The limit rod 31, the top surface of the limit rod 31 is provided with a protrusion 311 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com