Low-temperature curing powder coating and preparation method thereof

A powder coating, low temperature technology, applied in the direction of powder coating, polyester coating, epoxy resin coating, etc., to achieve the effect of excellent hardness and good leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] A kind of low-temperature curing powder coating, it is made by following weight (kg) raw material:

[0033] Carboxylated polyester (acid value 35mg KOH / g) 40

[0034] epoxy resin 22

[0035] Crystalline Carboxyl Compound 10

[0036] Filler 25

[0037] Leveling agent 1.5

[0038] Tribenzylethylphosphonium bromide 0.5

[0039] Benzoin 0.7

[0040] Antistatic agent 0.3

[0041] The preparation method of above-mentioned low-temperature curing powder coating, it may further comprise the steps:

[0042] (1) All materials are weighed according to the ratio, placed in a high-speed mixer, and mixed for 2 minutes;

[0043] (2) The twin-screw foundation is adopted, the screw arrangement is a standard arrangement, and the extrusion temperature is controlled at 85 o around C;

[0044] (3) The extruded tablet is crushed to 40um particles;

[0045] (4) Particles are sieved with 180 mesh and packed for later use.

example 2

[0047] A kind of low-temperature curing powder coating, it is made by following weight (kg) raw material:

[0048] Carboxylated polyester (acid value 70mg KOH / g) 30

[0049] Epoxy 30

[0050] Crystalline Carboxylate 8

[0051] Filler 28

[0052] paint 2

[0053] Leveling agent 1.0

[0054] Tetrabutylammonium bromide 0.8

[0055] Benzoin 0.5

[0056] Antistatic agent 0.2

[0057] The preparation method of above-mentioned low-temperature curing powder coating, it may further comprise the steps:

[0058] (1) All materials are weighed according to the ratio, placed in a high-speed mixer, and mixed for 2 minutes;

[0059] (2) The twin-screw foundation is adopted, the screw arrangement is a standard arrangement, and the extrusion temperature is controlled at 88 o around C;

[0060] (3) The extruded material is crushed to 45um particles;

[0061] (4) Particles are sieved with 180 mesh and packed for later use.

example 3

[0063] A kind of low-temperature curing powder coating, it is made by following weight (kg) raw material:

[0064] Carboxylated polyester (acid value 55mg KOH / g) 40

[0065] epoxy resin 20

[0066] Crystalline Carboxylate 5

[0067] Filler 25

[0068] Pigment 8

[0069] Leveling agent 1.0

[0070] Benzyltriethylammonium bromide 0.3

[0071] Benzoin 0.5

[0072] Antistatic agent 0.2

[0073] The preparation method of above-mentioned low-temperature curing powder coating, it may further comprise the steps:

[0074] (1) All materials are weighed according to the ratio, placed in a high-speed mixer, and mixed for 2 minutes;

[0075] (2) The twin-screw foundation is adopted, the screw arrangement is a standard arrangement, and the extrusion temperature is controlled at 90 o around C;

[0076] (3) The extruded material is crushed to 40um particles;

[0077] (4) Particles are sieved with 180 mesh and packed for later use.

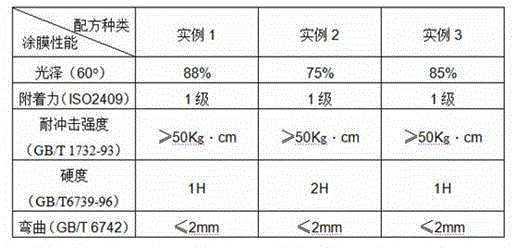

[0078] The powder coatings prepared by the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap