Premixing type pressure-adjusting secondary fuel gas nozzle and method

A pressure regulation, gas burner technology, applied in the field of kiln combustion, can solve the problems of excess combustion-supporting air, waste of combustion-supporting air and natural gas, and achieve the effects of reducing consumption, increasing sintering speed, and improving sintering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

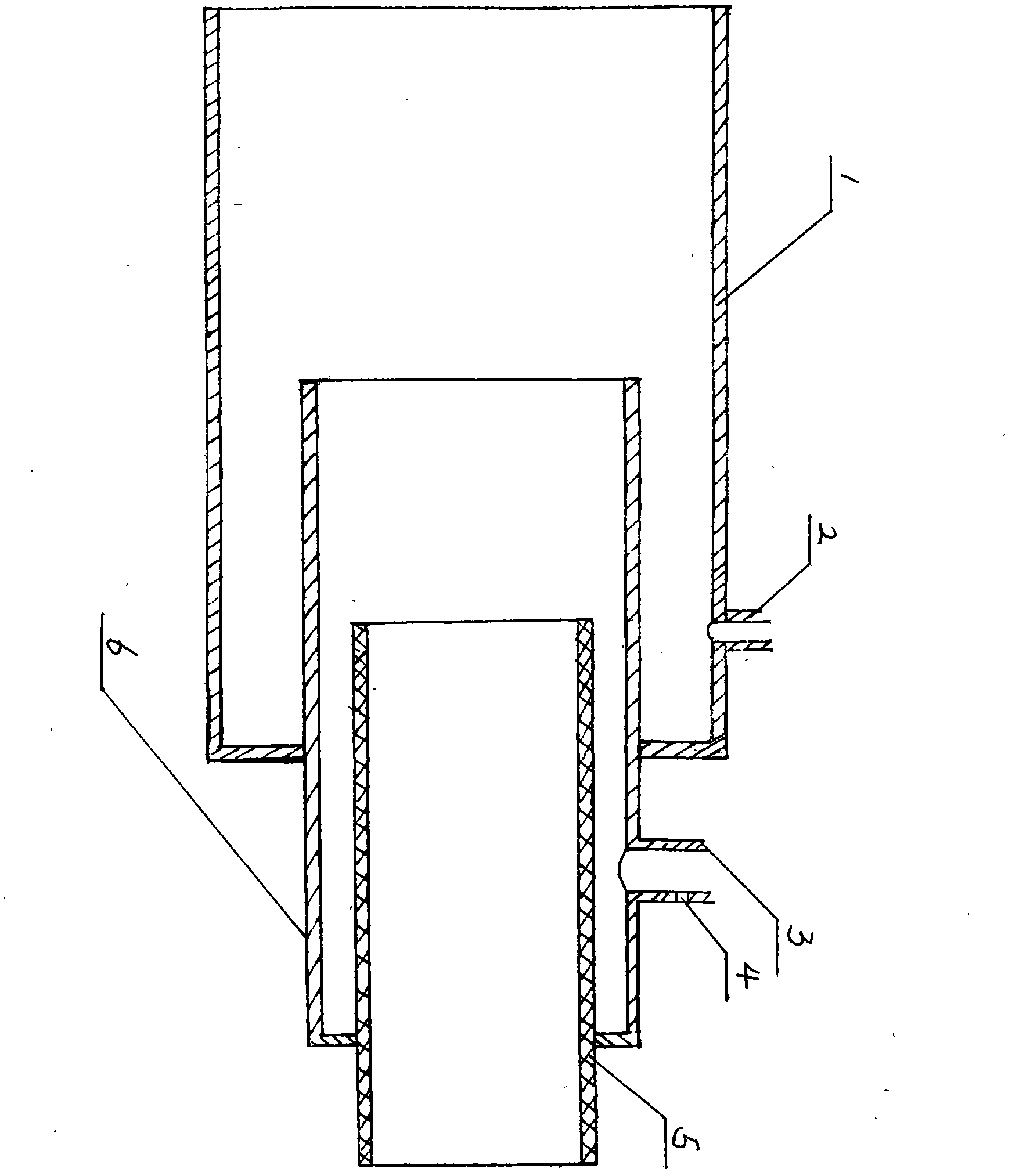

[0009] Such as figure 1 The specific embodiment of the premixed pressure regulating secondary gas burner and method of the present invention is shown, which is characterized in that a gas pipe 5 is provided, the gas pipe 5 is fixedly linked with the mixing pipe 6, and the mixing pipe 6 is set outside the gas pipe 5 , the mixing pipe 6 is provided with a secondary air outlet 3, the secondary air outlet 3 is provided with a pressure gauge interface 4, the mixing pipe 6 is fixedly linked with the air inlet pipe 1, the air inlet pipe 1 is set outside the mixing pipe 6, and the air inlet pipe 1 Main air outlet 2 is arranged on it.

[0010] In the present invention, the accurate dosage of natural gas and combustion-supporting air is judged by observing the change of the pressure gauge, so that the natural gas and combustion-supporting air are fully mixed in the mixing tube. Reasonable gas volume Mixing gas can reduce gas consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com