Double-ring-shaped integrated thermopile sensor

A technology that integrates pyroelectricity and sensors. It is used in instruments, thermometers, and scientific instruments that use electrical/magnetic components directly sensitive to heat. It can solve the measurement requirements that cannot meet high sensitivity and high measurement accuracy. , restricting the scope of use, etc., to achieve the effect of improving measurement accuracy and sensitivity, small relative error, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

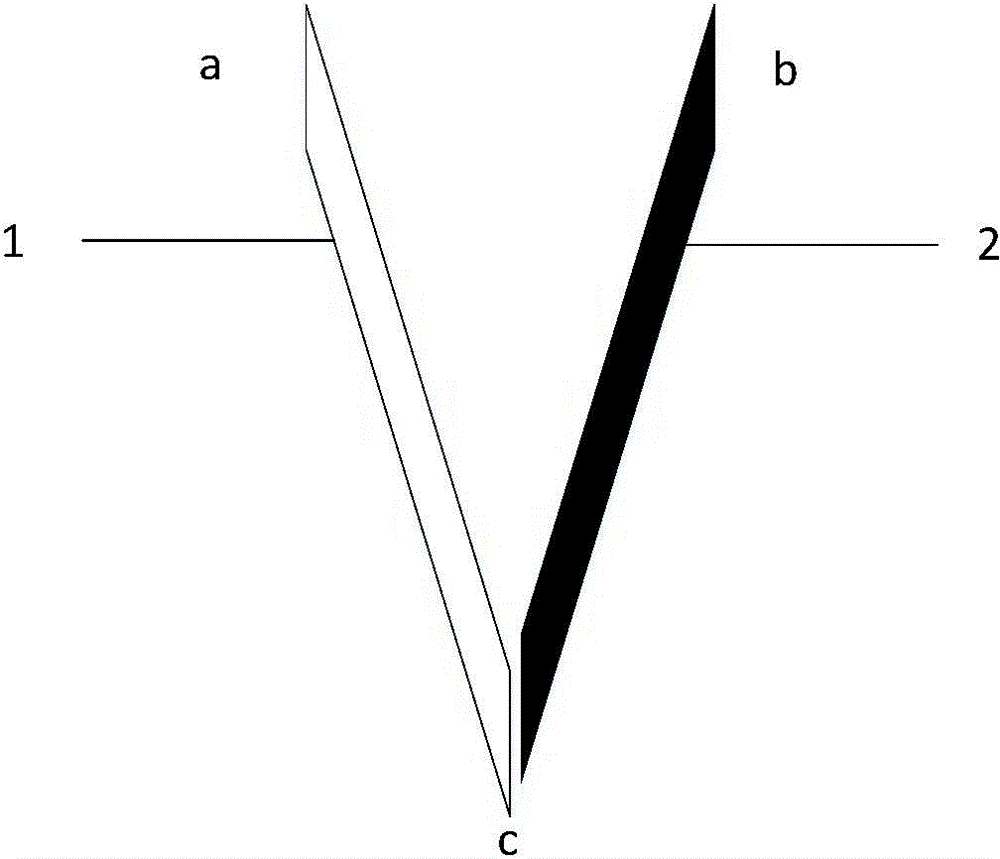

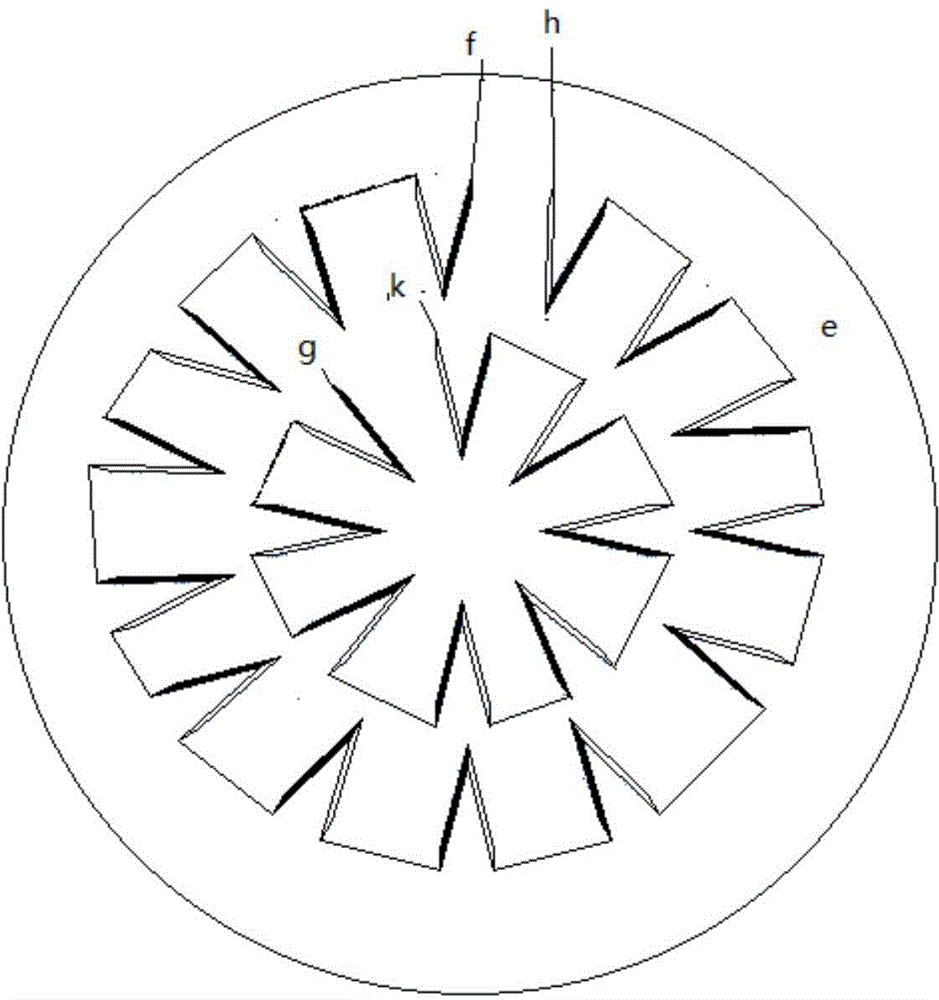

[0026] Such as image 3 As shown, it is a double-ring integrated thermopile sensor formed by V-type thermocouples connected in series. On the substrate e, there are inner rings and outer rings respectively composed of multiple thermocouples connected in series. The high temperature ends of all inner ring thermocouples are distributed in a small area centered on the center of the ring. This area is called temperature The sensing area is used to receive the infrared signal from the detection object, and its size is related to the size of the outer ring of the thermopile sensor. Taking a thermopile with a diameter of 200 μm as an example, the high-temperature ends of the inner ring thermocouples are distributed in an area with a diameter of about 30 μm centered on the center of the inner ring. The cold end one and the cold end two of the inner ring thermocouple are close to the high temperature end of the outer ring thermocouple. The first thermal electrode of the adjacent ther...

Embodiment 2

[0028] Such as Figure 4 As shown, it is a double-ring integrated thermopile sensor formed by grouping and connecting V-type thermocouples in series. The difference between this example and Example 1 lies in the connection mode of the thermocouple. Taking the inner ring as an example, the thermocouples in it are divided into two groups, the first group of thermocouples and the second group of thermocouples are distributed on the inner ring, and the first thermal electrode of the first thermocouple of the adjacent thermocouples in the same group is connected with The second thermal electrode of the second thermocouple is connected in series. In this way, the thermocouples in the same group are connected in series, and then the first thermal electrode (or second thermal electrode) in the first group of thermocouples is connected to the second thermal electrode. The second thermal electrodes (or the first thermal electrodes) in the group of thermocouples are connected in series,...

Embodiment 3

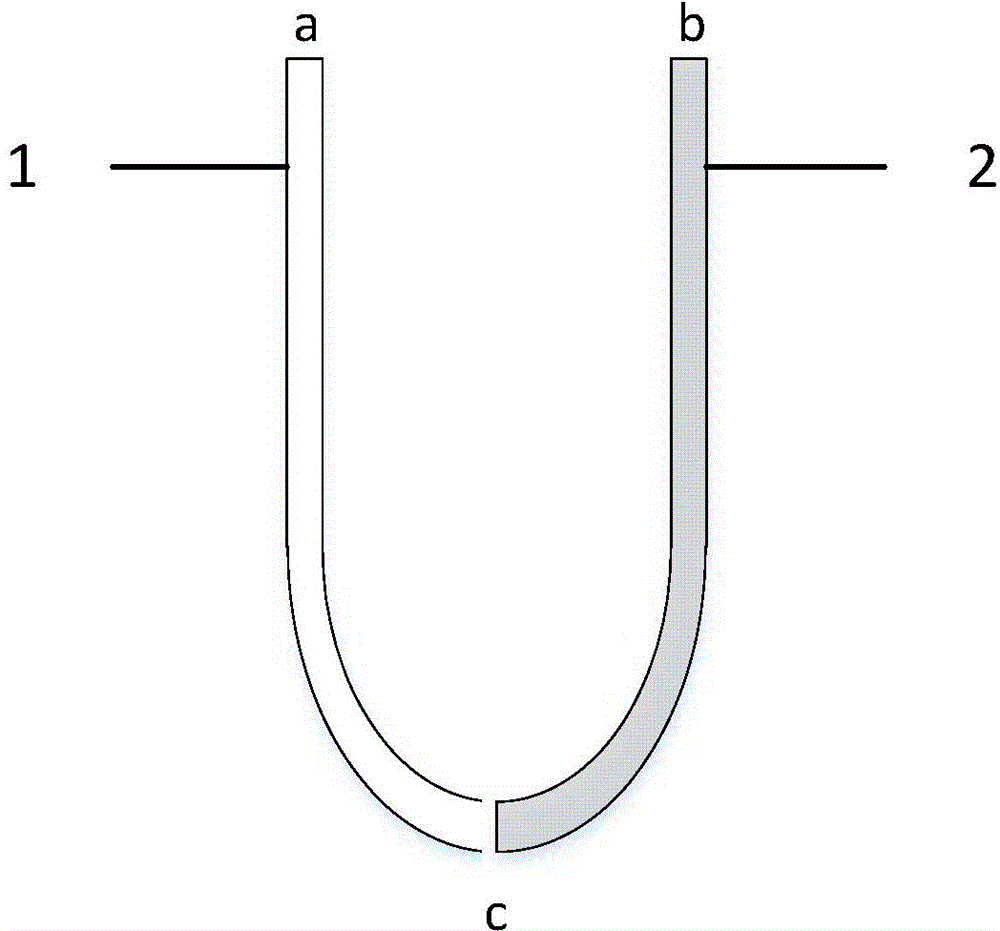

[0030] Such as Figure 5 As shown, it is a double-ring integrated thermopile sensor formed by connecting U-shaped thermocouples in series. The connection method is similar to that of Example 1, but U-shaped thermocouples are used, and the double-ring integrated thermopile sensor formed by it is more compact than the double-ring integrated thermopile sensor formed by V-shaped thermocouples in Example 1. In this example, the inner-ring lead-out electrodes f, h and the outer-ring lead-out electrodes g, k are respectively connected to the secondary measurement structure, and the thermomotive force on the electrodes f, h and electrodes g, k are calculated again in the secondary measurement structure In order to get the thermoelectric potential generated by the whole thermopile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com