Adjustable constant speed sampling system

A sampling system, adjustable technology, applied in the direction of the sampling device, etc., can solve the problems of unstable air pressure of the sampling device, the position of the main sampling tube cannot be adjusted, etc., to achieve the effects of avoiding vibration, ensuring accuracy, and uniform standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

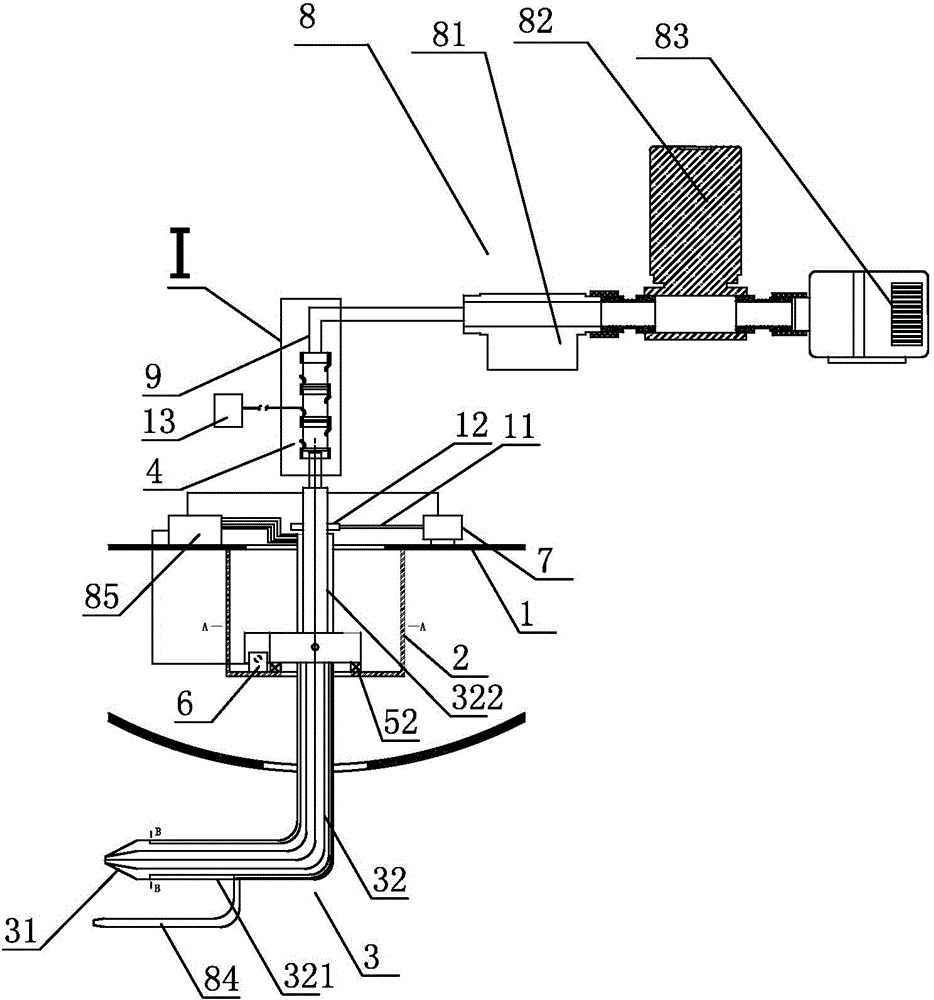

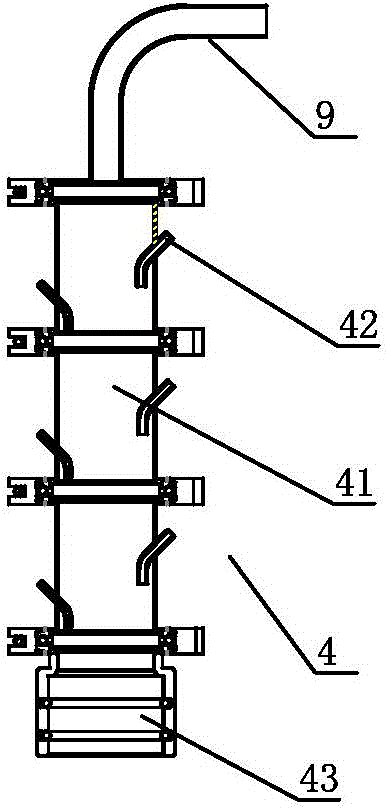

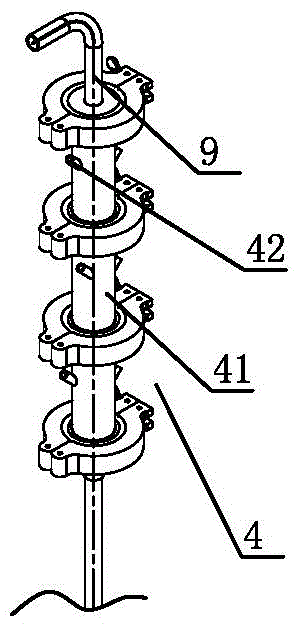

[0024] like figure 1 As shown, the adjustable constant velocity sampling system of the present embodiment includes a cabin panel 1, a bracket 2 fixed below the cabin panel 1, a constant velocity sampling device 3 installed on the bracket 2, and is communicated with the constant velocity sampling device 3. The main sampling pipe 4 and the particle monitoring sampling instrument 13 communicated with the main sampling pipe 4, the main sampling pipe 4 is composed of a plurality of joint pipes 41, the joint pipes 41 are provided with constant velocity sampling joints 42, and the main sampling pipe 4 passes through the constant velocity The sampling joint 42 is connected with the particle monitoring sampling instrument 13 .

[0025] Isokinetic sampling device 3 comprises isokinetic head 31 and isokinetic tube 32, and isokinetic tube 32 is " L " shape pipe, and isokinetic head 31 is detachably installed in the port of transverse tube 321 of isokinetic tube 32 , isokinetic tube The v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com