Cigarette weight collecting device and method

A collection device and weight technology, which is applied in the field of cigarette weight collection and processing, can solve problems such as abnormal signals and shredded tobacco signal transmission noise, and achieve the effects of simple measurement methods, accurate weight deviation calculation and control, and overcoming noise and abnormal signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

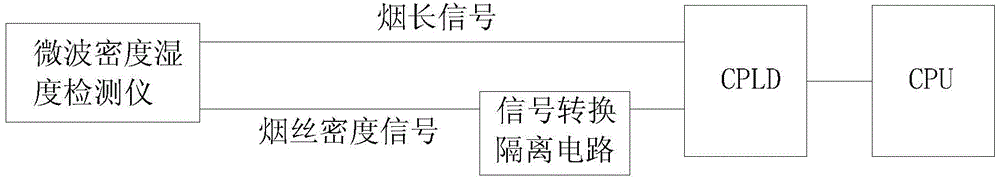

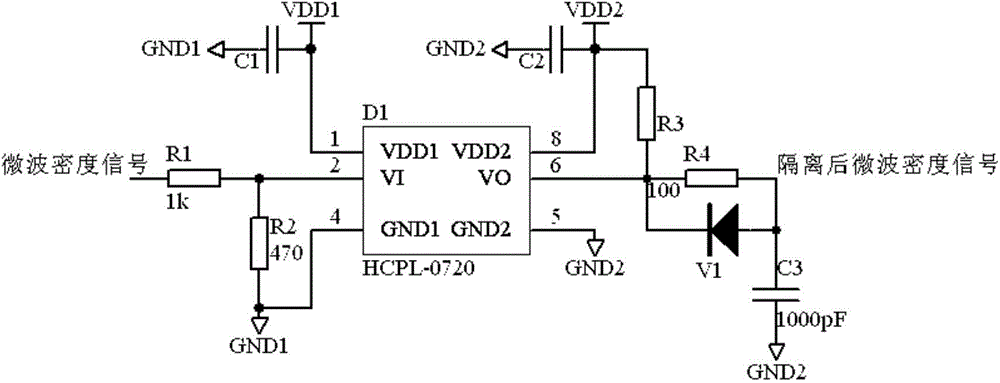

[0013] see figure 1 As shown, a cigarette weight acquisition device includes a microwave density and humidity detector, a signal conversion isolation circuit, a CPLD, and a CPU. The signal output terminals of the microwave density and humidity detector are respectively connected to the input of the signal conversion isolation circuit and the CPLD, The output of the conversion isolation circuit is connected to the input of the CPLD, and the output of the CPLD is connected to the input of the CPU. The signal conversion isolation circuit is composed of a high-speed optocoupler model HCPL-0720, and a voltage divider circuit and an RCD circuit are built on the high-speed optocoupler.

[0014] In the above signal conversion isolation circuit, the VDD1 pin of the high-speed optocoupler of model HCPL-0720 is connected to the voltage VDD1, and the VDD2 pin is connected to the voltage VDD2, and the VDD1 pin of the high-speed optocoupler is connected to the common ground GND1 and VDD2 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com