A research device and method for electrochemical corrosion behavior in spray splash zone

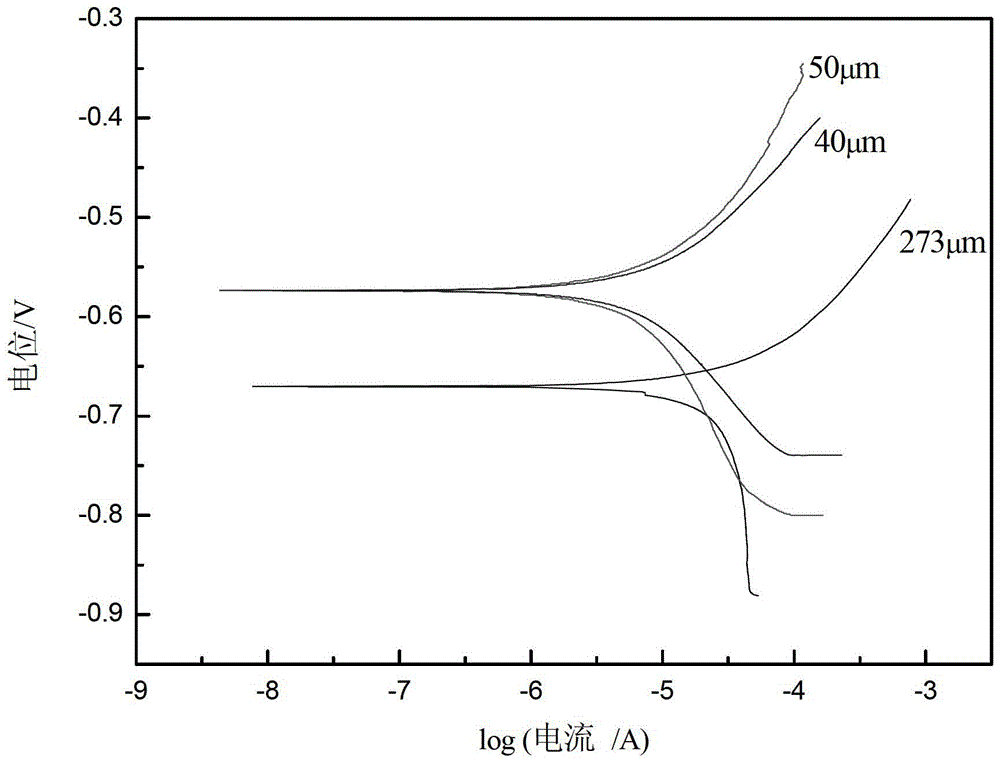

A spray splash and electrochemical technology, applied in electromagnetic measuring devices, measuring devices, weather resistance/light resistance/corrosion resistance, etc., can solve the problems of inability to continuously and effectively control liquid film measurement, large liquid film thickness error, etc., and achieve high precision , The liquid film thickness measurement is accurate and the effect of ensuring authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

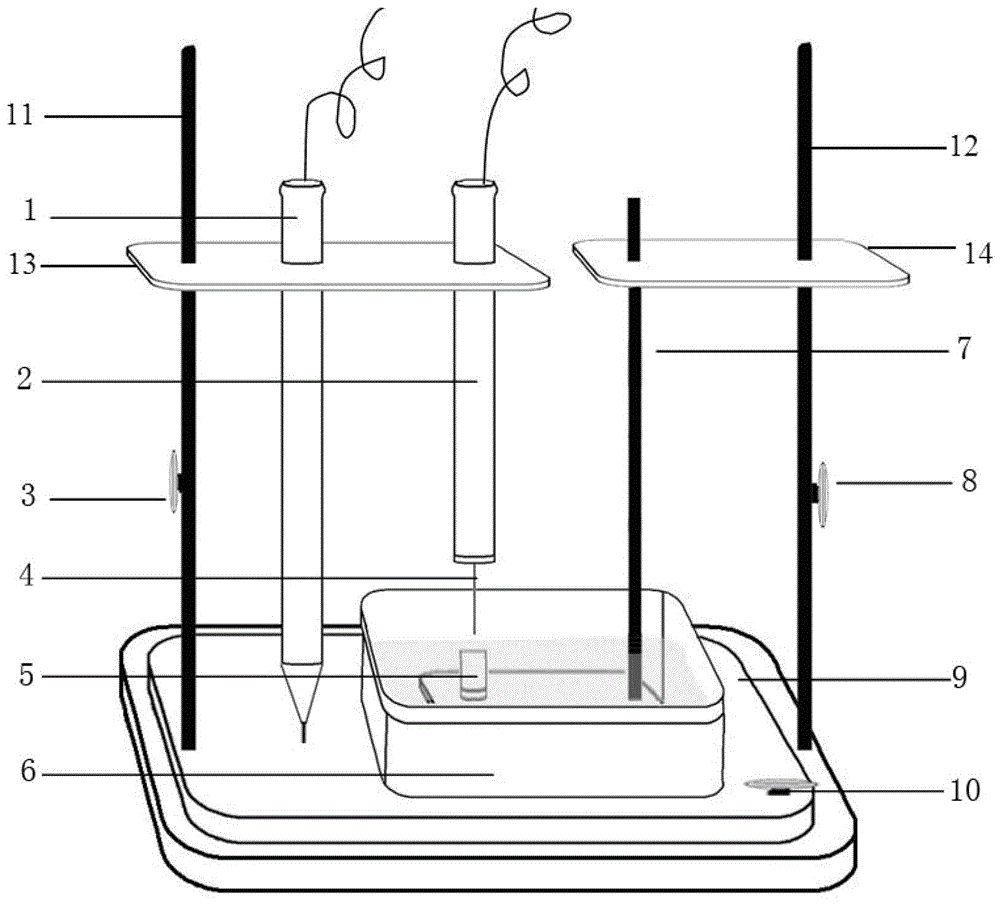

[0031] Such as figure 1 Shown is a schematic diagram of the thin-layer liquid film thickness measuring device of the present invention. Including: first guide rail support 11, second guide rail support 12, XY axis moving platform 9, displacement sensor 1 (with an accuracy of 1 μm), insulating cylinder 2, high-precision digital display instrument, external DC power supply, multi-channel data recorder, Platinum wire probe, working electrode 5, T-shaped electrode loading platform 7, bottom platform and container 6.

[0032] Wherein, the first guide rail bracket 11 is fixed on the side of the XY-axis moving platform 9, and a strip-shaped iron plate platform 13 is installed on the upper part of the first guide rail bracket 11, and the displacement sensor 1 and the insulating cylinder 2 pass through the above-mentioned first strip-shaped iron plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com