Bayesian Network Fault Prediction Method for Modular Complex Equipment

A Bayesian network and fault prediction technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as poor practicability, achieve strong practicability, reduce maintenance costs, and improve maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

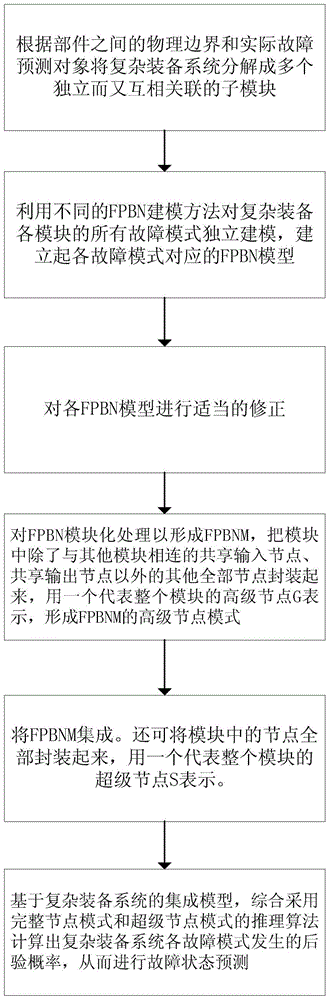

[0047] refer to Figure 1-7 . The specific steps of the Bayesian network fault prediction method for modular complex equipment of the present invention are as follows:

[0048] Step 1. According to the physical boundary between components and the actual fault prediction object, the complex equipment system is decomposed into multiple independent and interrelated sub-modules. The specific method is as follows:

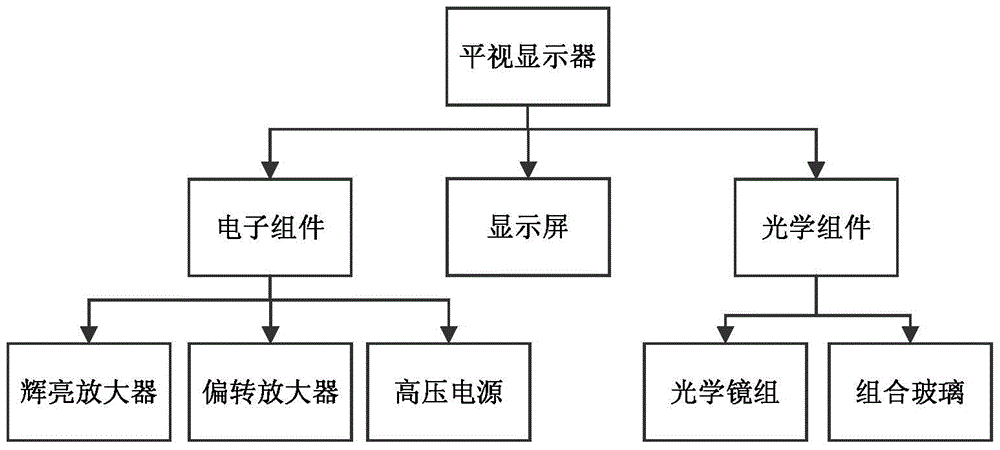

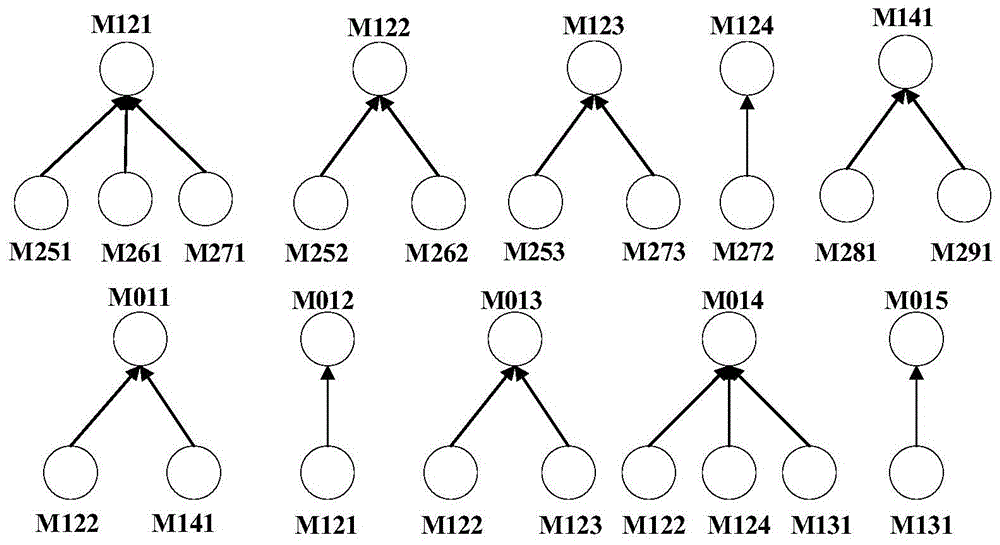

[0049] In this embodiment, taking "head up display (HUD)" as the failure mode, according to the original design data of HUD and its system structure composition, first decompose the HUD into functional modules of different levels according to the function, and the decomposed system modules such as figure 2 shown. Table 1 lists the failure modes and descriptions corresponding to the modules at each level of the HUD.

[0050] Table 1 Failure modes of each module of HUD

[0051] mode number level Module number module failure mode coding 1 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com