Fireproof cable sleeve

A technology for fireproof casing and cable, applied in electrical components and other directions, can solve the problems of inability to prevent and protect cable fire, time-consuming, power cable fire and burn, etc., to improve the safety performance of electricity consumption, reduce the risk of fire, shorten the The effect of response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

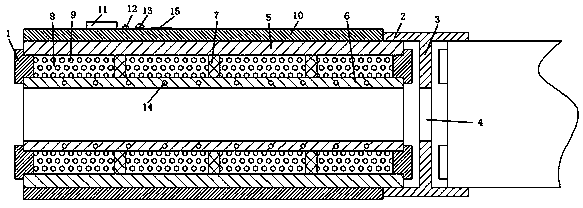

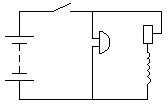

[0013] Such as figure 1 and 2 As shown, a fireproof casing for cables is composed of a wire protection sleeve, a connecting sleeve, a sealing plug 1 and a wire breakage alarm system. The wire protection sleeve is composed of at least two wire-passing pipes, and It is connected through a connecting sleeve. The connecting sleeve is composed of a pipe wall 2 and a baffle 3, wherein the pipe wall 2 and the baffle 3 are of an integrated structure and the axial section is "H" type, and the baffle 3 is additionally provided with The wire hole 4, the wire passing pipe is a hollow tubular structure, the pipe wall is composed of an insulating outer wall 5 and a hot-melt inner wall 6, wherein the distance between the insulating outer wall 5 and the hot-melt inner wall 6 is not less than 1 cm, and is composed of The ribs 7 are connected to form a fireproof cavity 8, the fireproof cavity 8 is distributed parallel to the axial direction of the wire passing pipe, the fire extinguishing cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com