Low-noise voltage-controlled oscillator biasing circuit and frequency source self-calibration method

A technology of voltage-controlled oscillators and bias circuits, applied in power oscillators, electrical components, etc., can solve the problems of increasing circuit costs, high noise of voltage dividing circuits, and increasing the output pins of bias circuits, etc., to reduce the number of pins , the output noise is small, and the effect of avoiding changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

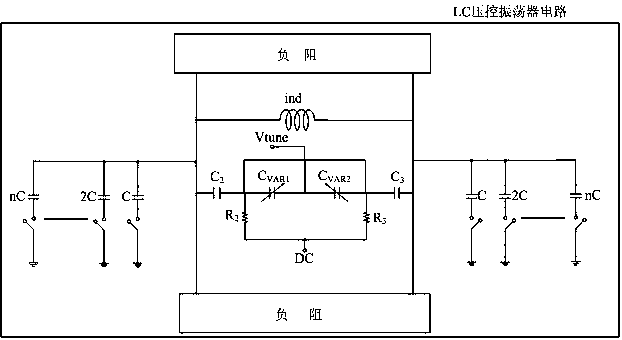

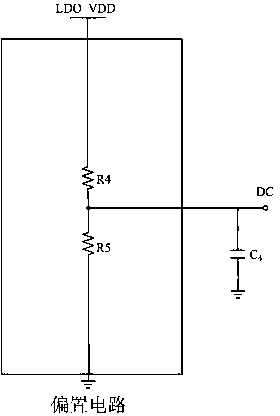

[0024] Such as Figure 4 As shown, the low-noise voltage-controlled oscillator bias circuit is used in conjunction with the LC voltage-controlled oscillator to provide a voltage bias point for the LC voltage-controlled oscillator in the frequency source circuit. It consists of a constant voltage source LDO_VDD, a voltage divider circuit and Composed of filter capacitor C1, the voltage divider circuit includes a high-value poly resistor R1, a first bipolar junction transistor BJT1 and a second bipolar junction transistor BJT2 connected in series, and a high-value poly resistor R1 is connected in series with a BJT tube. The voltage divider circuit divides the voltage output by the LDO. The high value poly resistor R1 is connected to the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com