Fire-extinguisher placing box

A technology of fire extinguisher and placement box, which is applied in fire rescue and other directions to improve efficiency, provide overall performance, and facilitate installation and locking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

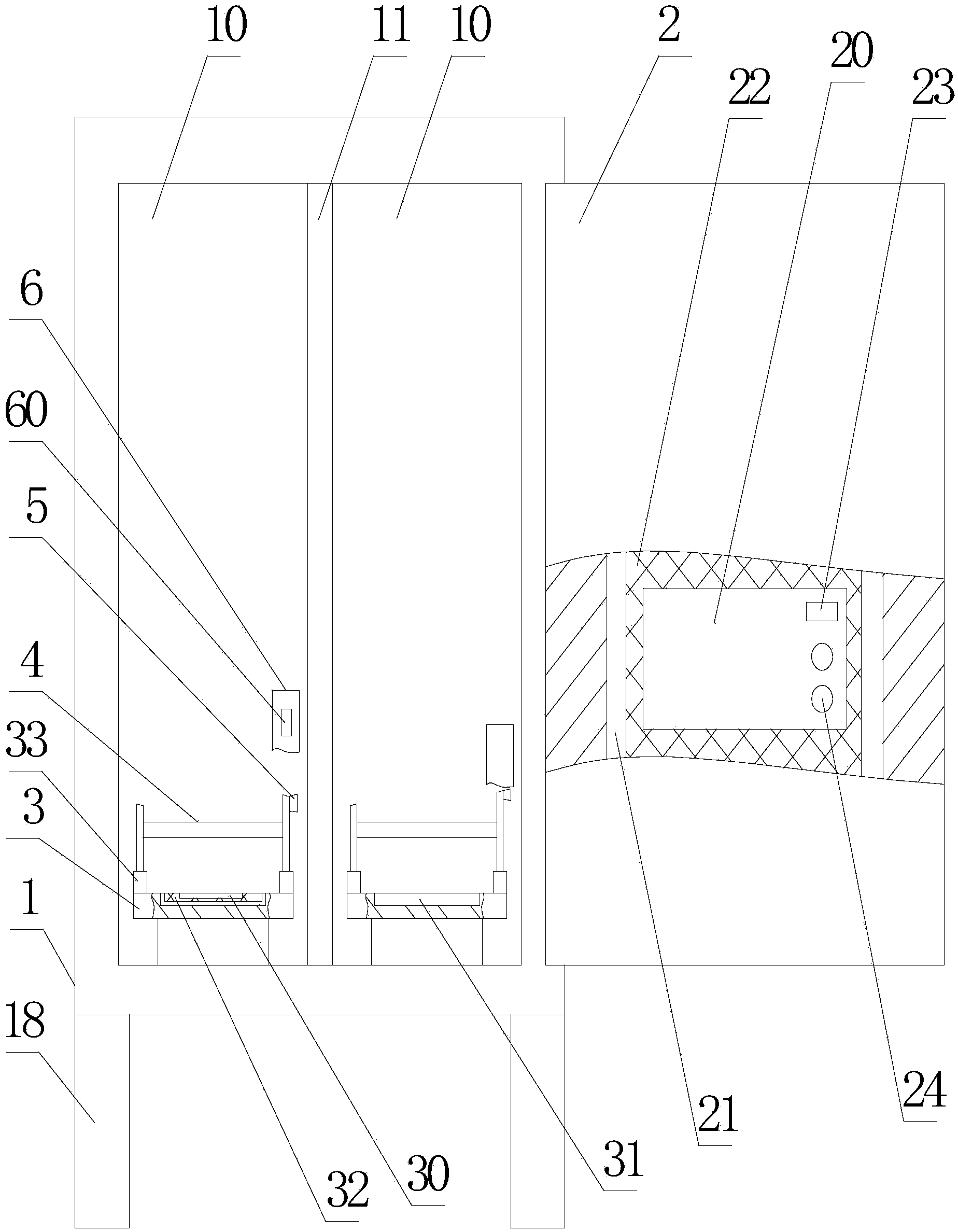

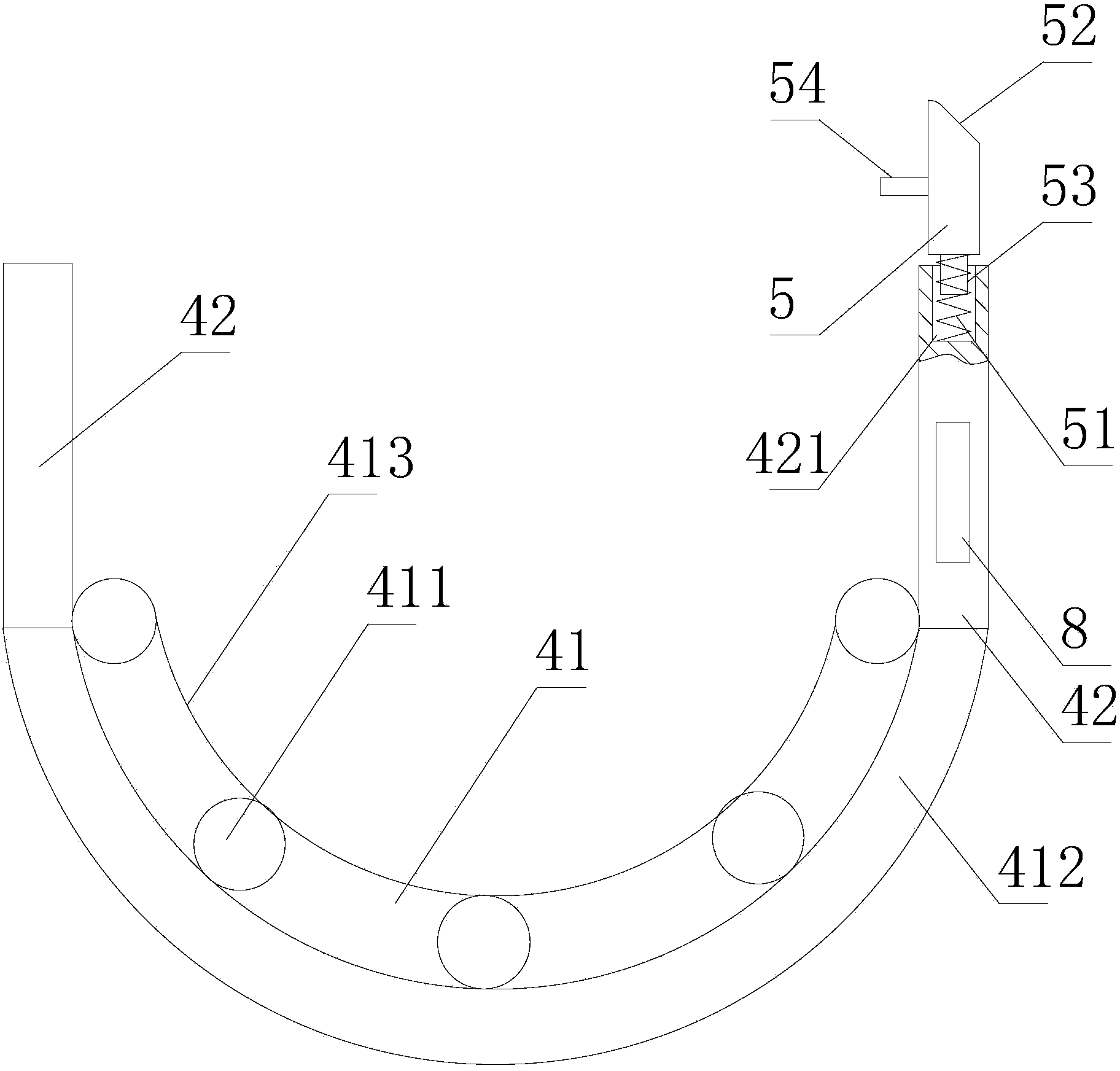

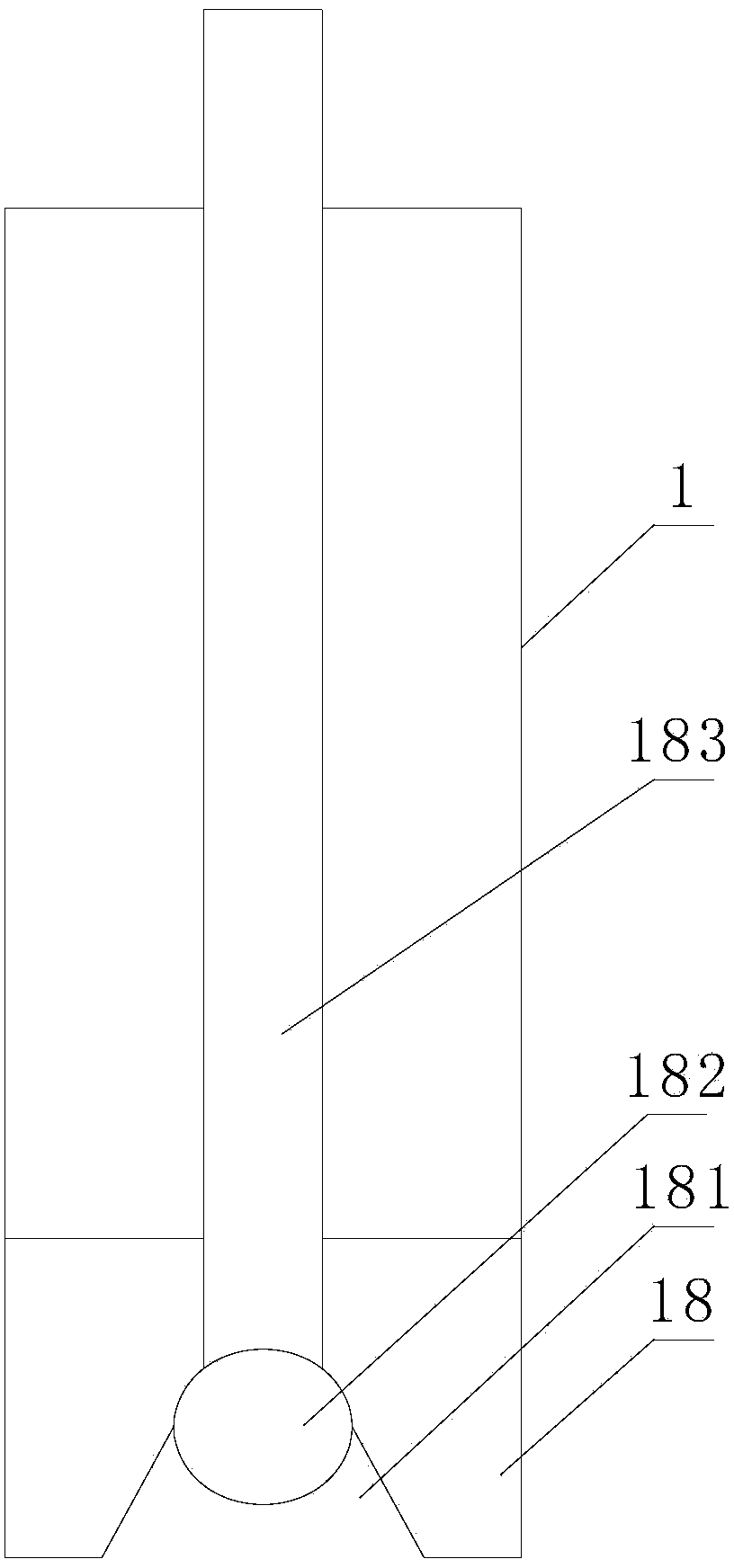

[0014] Such as figure 1 , figure 2 , image 3 As shown, a fire extinguisher storage box includes a box body 1, a sealing plate 2 that is rotatably connected to the box body 1, and at least one vertical wall that divides the box body 1 into at least two placement cavities 10 is provided in the box body 1. Straight partitions 11, a turntable 3 is provided at the bottom end of each placement chamber 10, and a placement assembly 4 that facilitates the placement of fire extinguishers is provided on each turntable 3, and the placement assembly 4 includes a circular arc portion 41, at least A first baffle plate 42 arranged on the arc portion 41 is movably connected with at least one locking tongue 5 for locking the turntable 3 in the box body 1, and the box body 1 is provided with There is a buckle 6 connected with the deadbolt 5, a weight sensor 30 for detecting the weight of the fire extinguisher is provided at the bottom of each turntable 3, and a display panel 20 connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com