Tube bending machine

A pipe bending machine and frame technology, applied in the direction of forming tools, feeding devices, positioning devices, etc., can solve the problems of wasting manpower, easily injuring operators, and shortages, and achieve the effect of ensuring the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

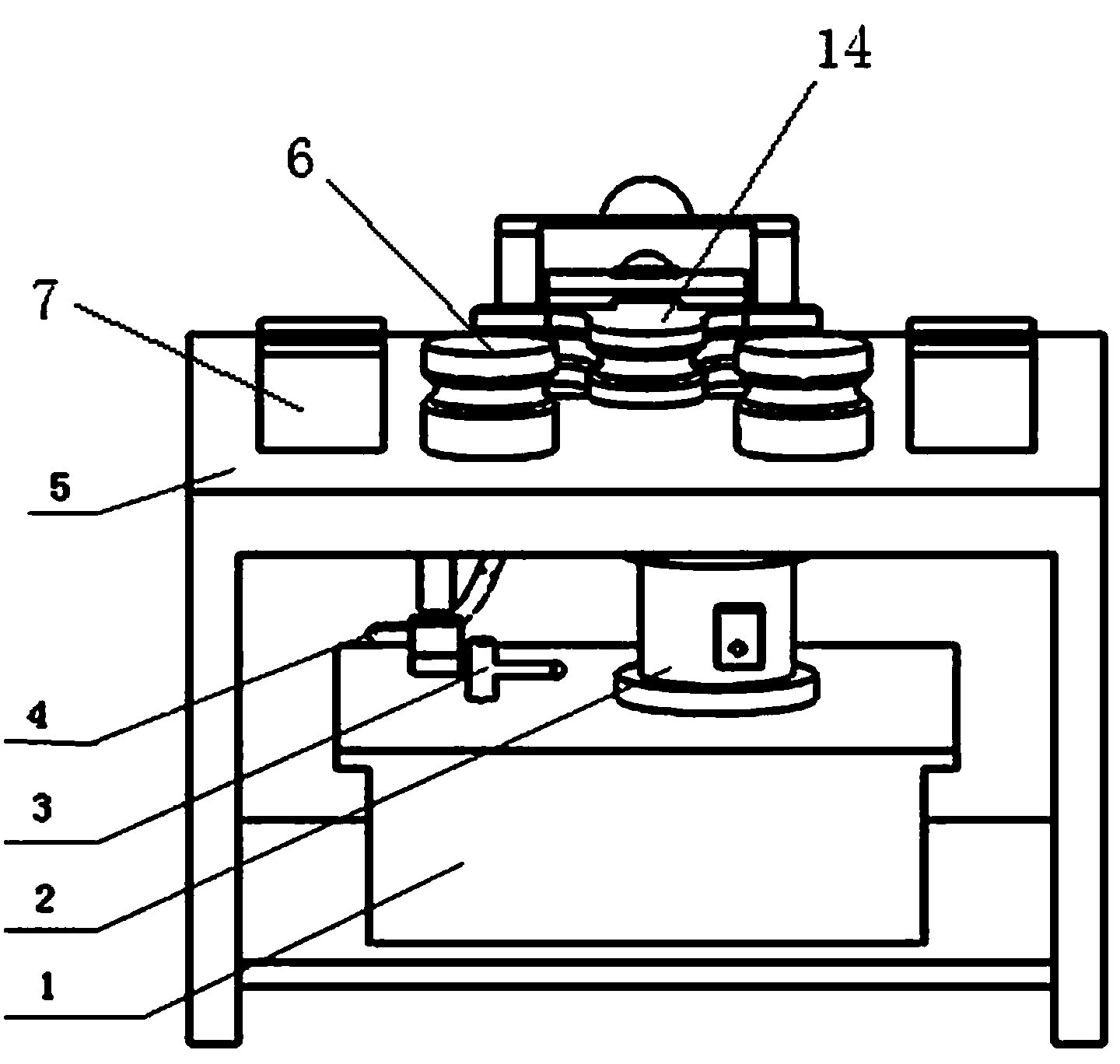

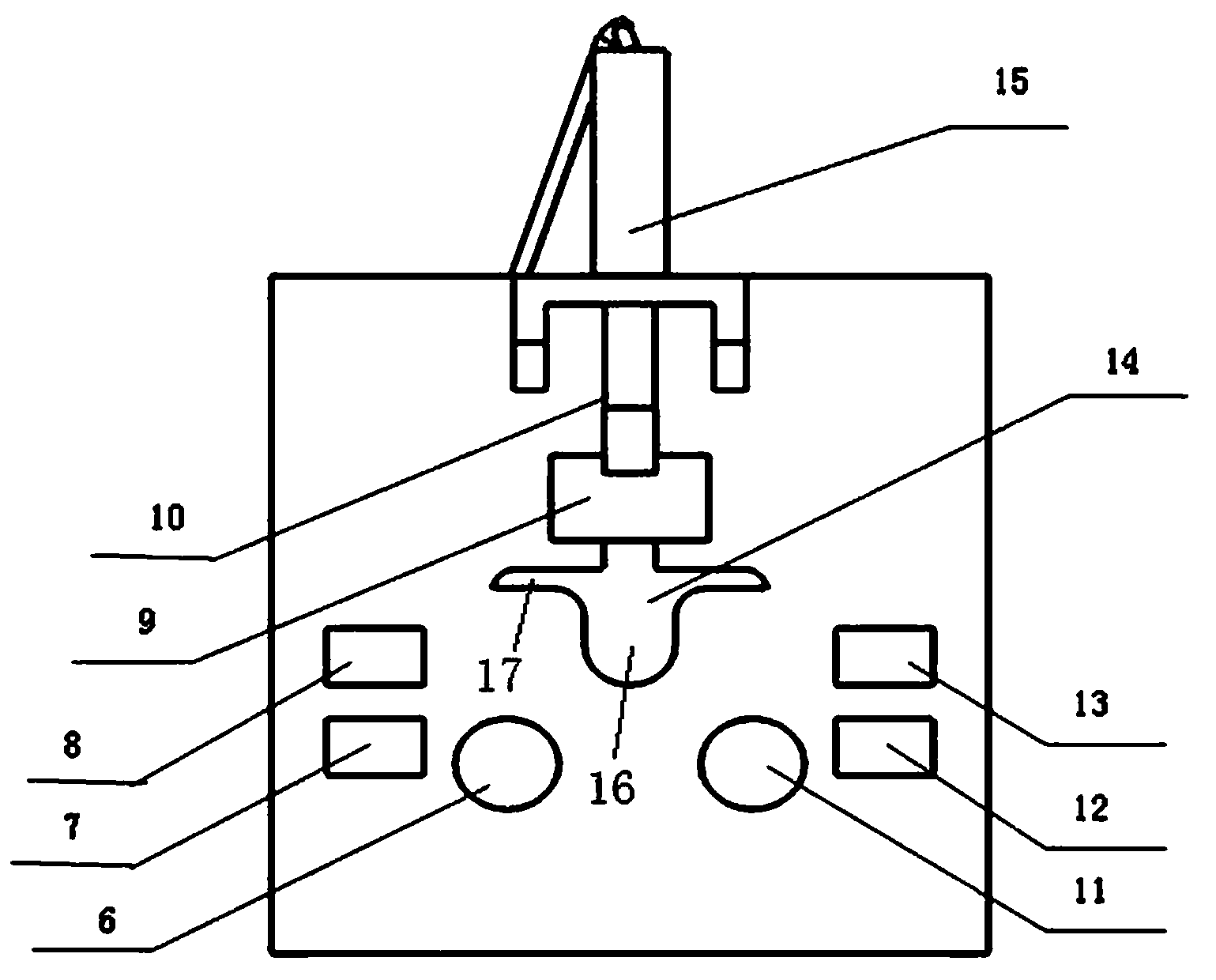

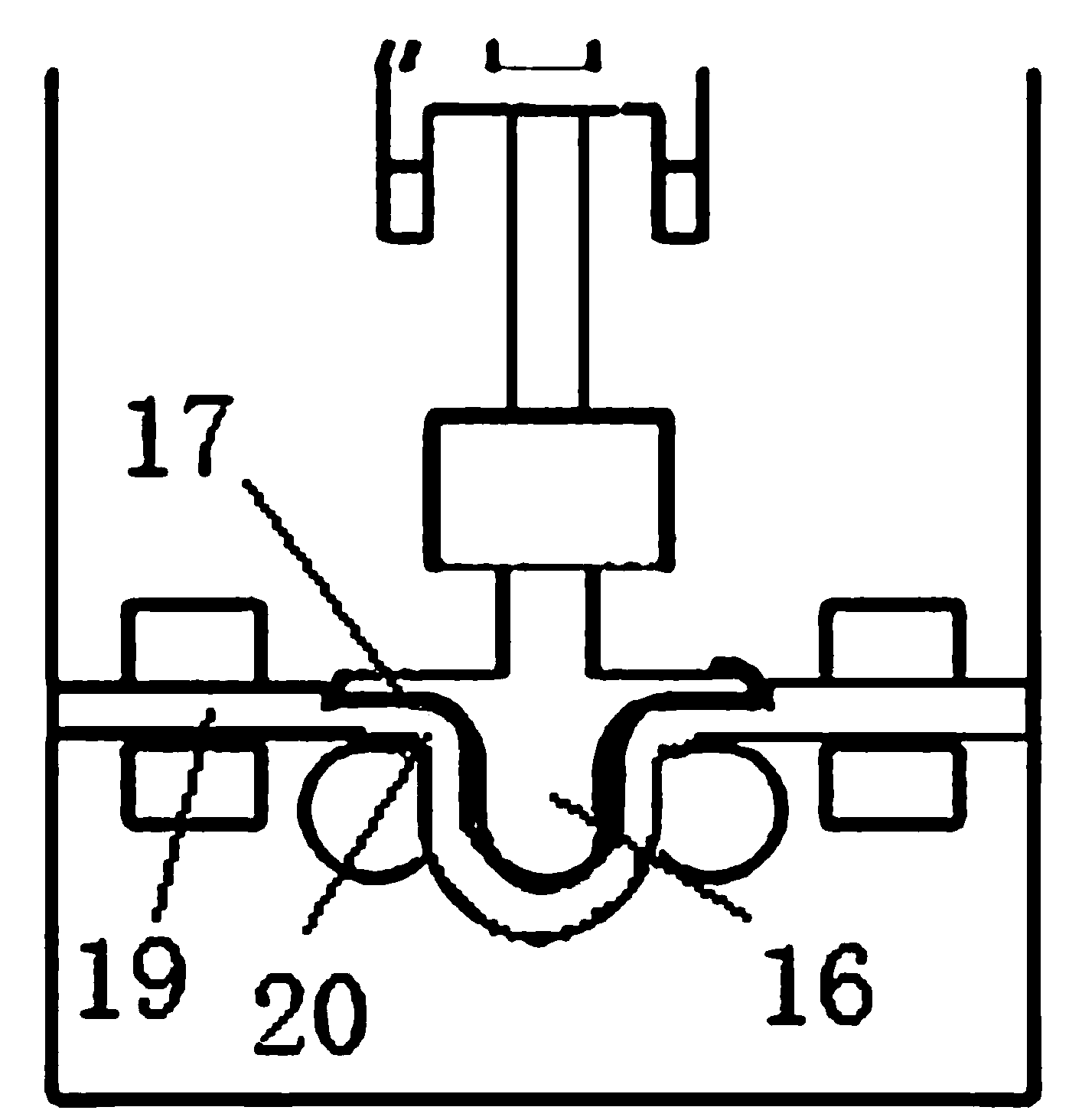

[0023] An example of a pipe bending machine Figure 1~7 Shown: including the frame, the frame includes the frame body and the upper table 5 and the lower table arranged on the frame body at intervals up and down, the frame is provided with a loading mechanism capable of outputting linear displacement motions in the front and rear directions, and the loading mechanism includes The loading oil cylinder 15 on the table, the piston rod 10 of the loading oil cylinder constitutes the power output end of the loading mechanism, the oil pump 1 driven by the motor 2 is arranged on the lower table, the oil outlet of the oil pump is connected with the oil inlet of the loading oil cylinder through the hydraulic pipeline 4 port connection. The piston rod of the loading cylinder is connected with the top bending die 14 through the connecting block 9. The connecting block moves along the front and rear directions and is assembled on the frame. The support wheel 6 and the support wheel 11 ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com