Elevator guide rail damping device

A technology of shock absorbing device and elevator guide rail, which is applied in transportation, packaging, elevators, etc. It can solve the problems of noise, affecting the effect of shock absorption and noise reduction, and failure to achieve the use effect, so as to prolong the service life and ensure the effect of shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

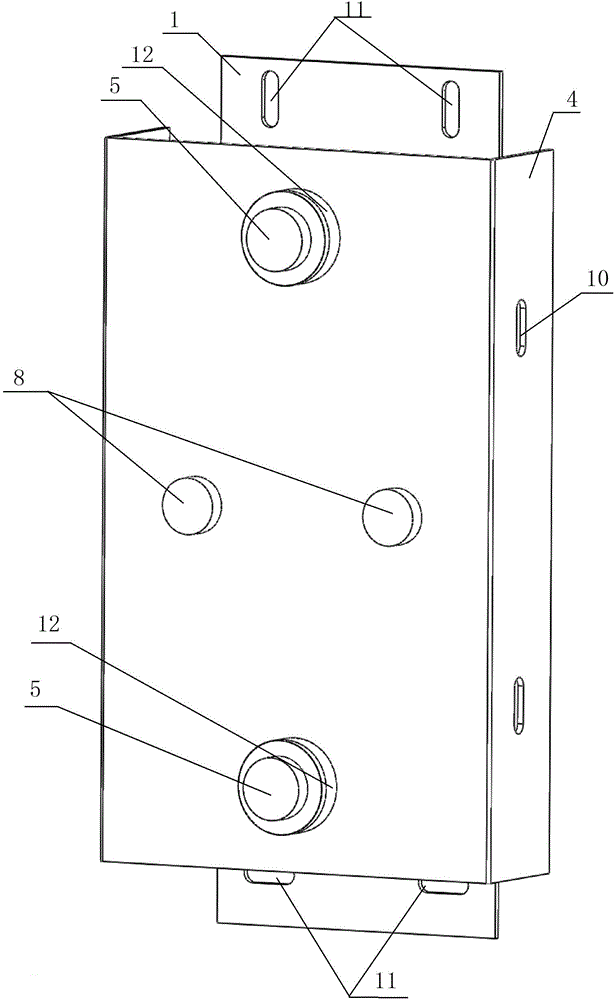

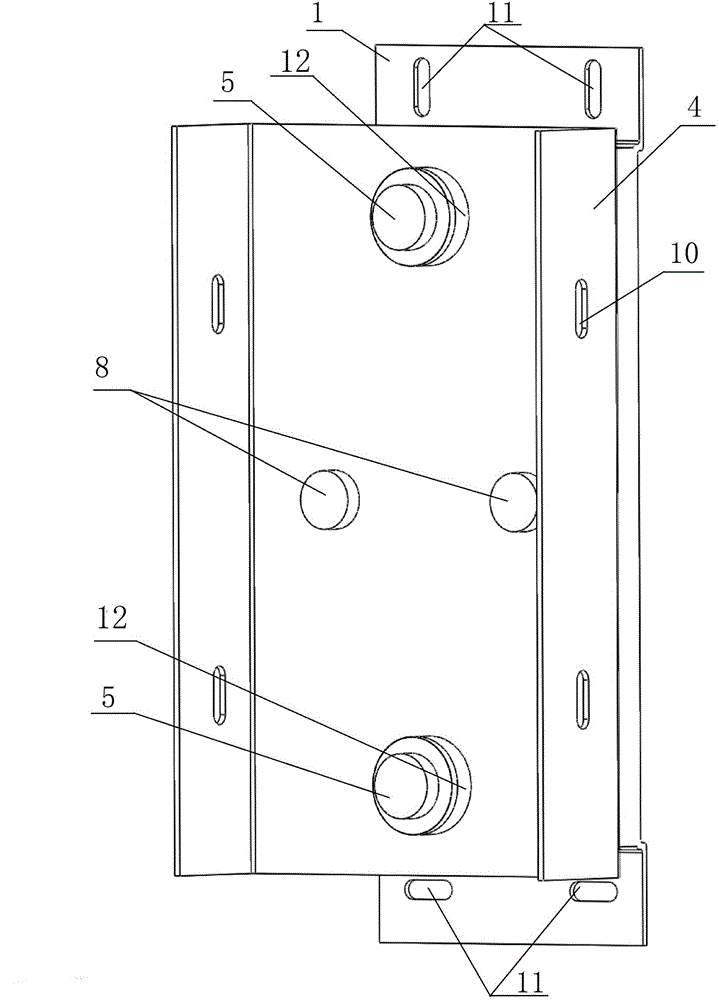

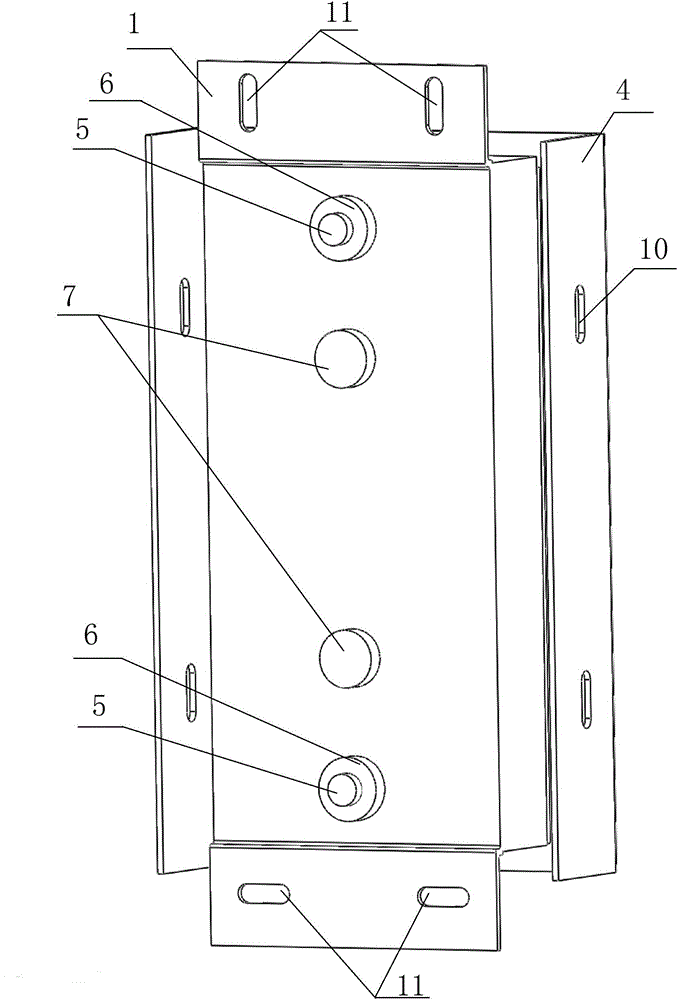

[0018] A damping device for elevator guide rails, such as Figure 1 to Figure 8 As shown, a vibration damping device for an elevator guide rail includes a wall mount 1, one side of the wall mount 1 is provided with a storage tank 2, an elastic shock absorber 3 is placed in the storage tank 2, and the guide rail support connecting cover 4 is covered in the storage tank 2 Above; the first bolts 8 are symmetrically arranged on both sides of the guide rail support connecting cover 4, run through the guide rail support connecting cover 4, and are screwed on the nuts deeply buried and fixed in the elastic shock absorbing pad 3 in advance, and the guide rail support connecting cover 4 and The elastic damping pad 3 is pressed tightly; the second bolt 7 is symmetrically arranged on the wall bracket 1, runs through the wall bracket 1, and is screwed on the nut deeply buried and fixed in the elastic damping pad 3 in advance, and the wall bracket 1 is pressed against the elastic damping p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com