Engine with variable compression ratio

A compression ratio, engine technology, applied in the direction of machine/engine, mechanical equipment, etc., can solve the problems of reducing compression ratio, high processing difficulty, inconvenient to put into production, etc., to achieve the effect of improving power, convenient control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

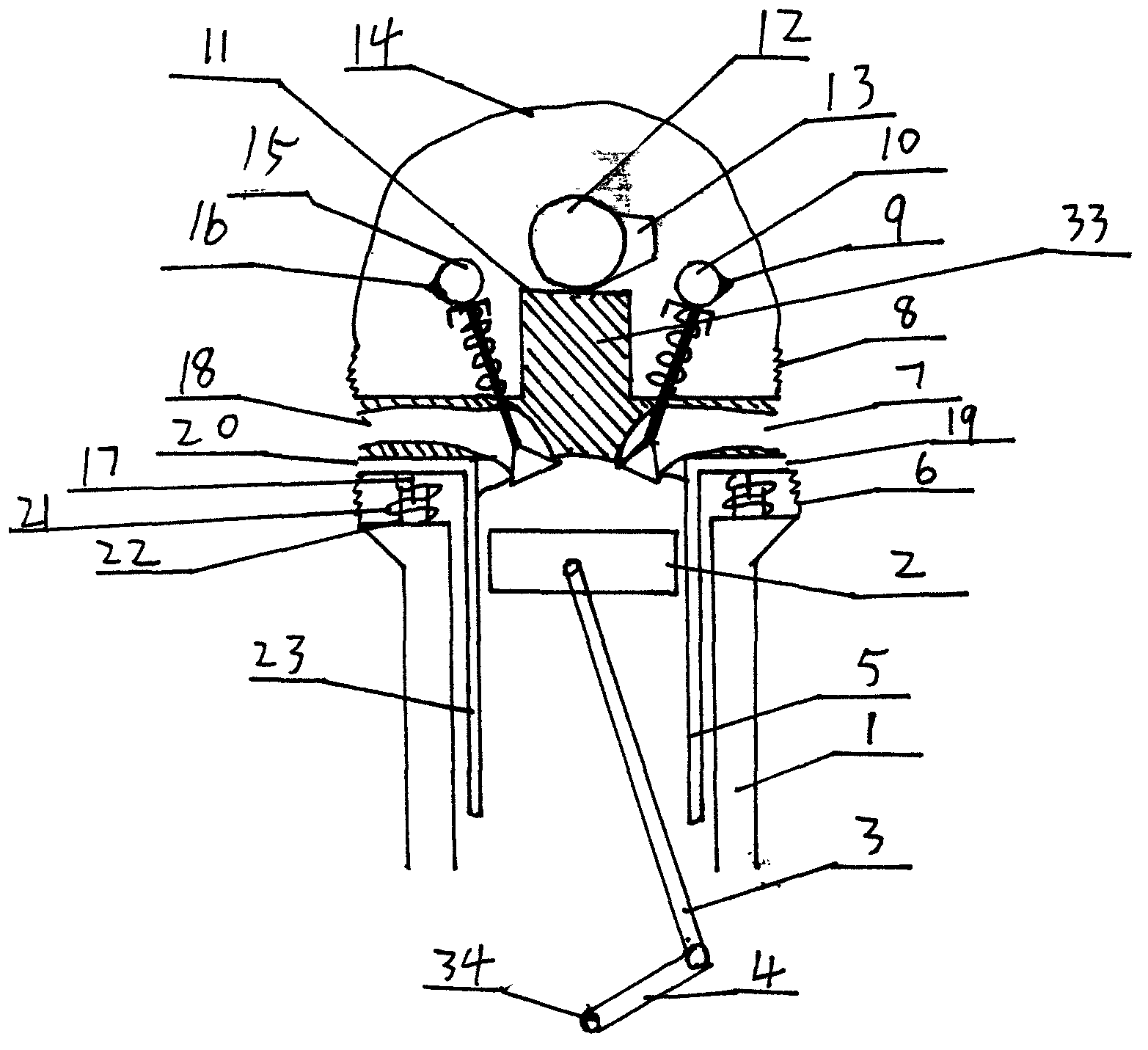

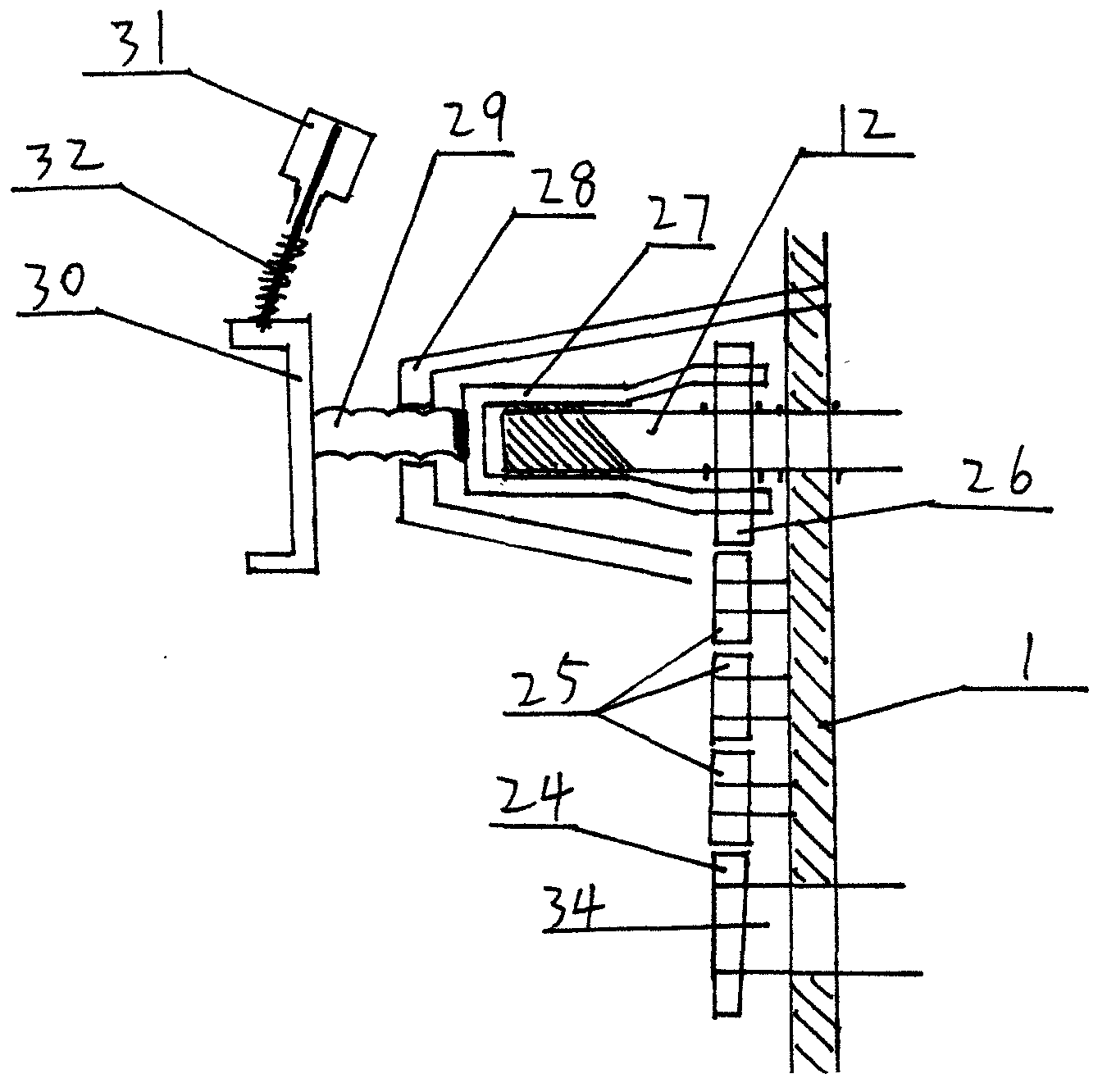

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

[0017] figure 1 with figure 2 As shown, it is a schematic diagram of the horizontal and vertical cross-sectional structure of the present invention, and the engine can be seen when it is cut open, including a cylinder block 1, a cylinder head 33 and a cylinder head cover 14 arranged on the cylinder head 33, and a cylinder barrel 5 is arranged in the cylinder block 1 , Piston 2, connecting rod 3, crank 4 and crankshaft 34.

[0018] The center of cylinder head 33 tops is provided with planar bar 11, and the top of planar bar 11 is provided with cam 13, and cam 13 is fixedly connected on the camshaft 12, and one end of camshaft 12 is provided with oblique tooth pattern, has inner cavity The sliding wheel 27 of the tooth pattern sleeve that matches with oblique tooth pattern. The sliding wheel 27 is driven by the crank gear 24 at one end of the crankshaft 34, and the driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com