fan

A fan and shaft column technology, applied in the fan field, can solve problems such as noise generation, poor efficiency, and reduced pressure difference between the upper and lower airfoils.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

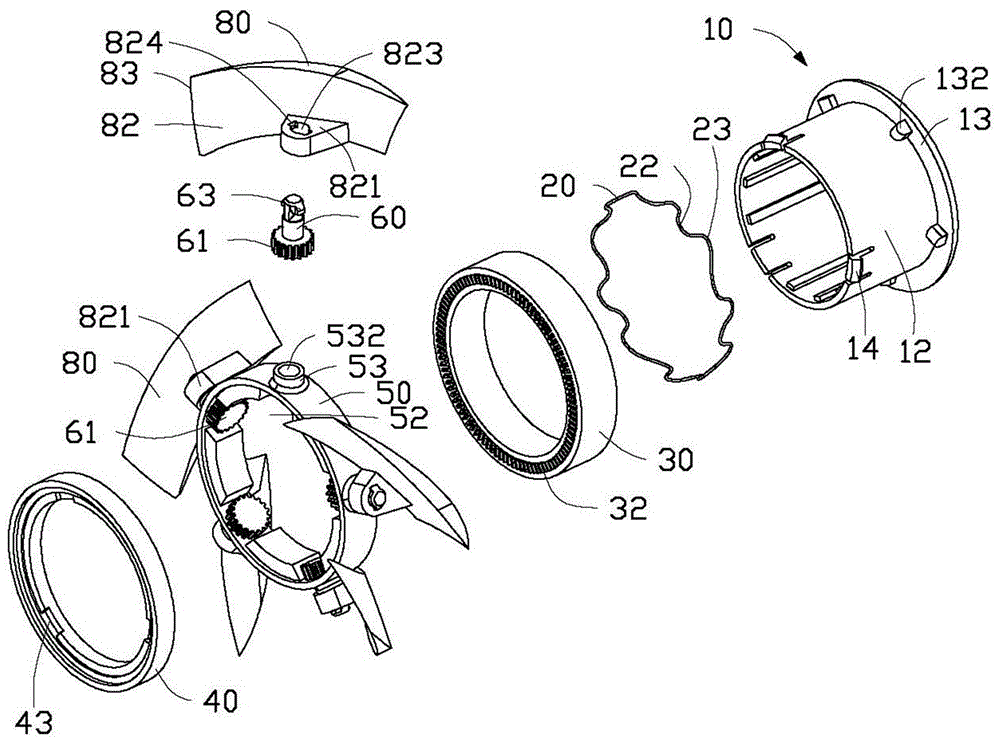

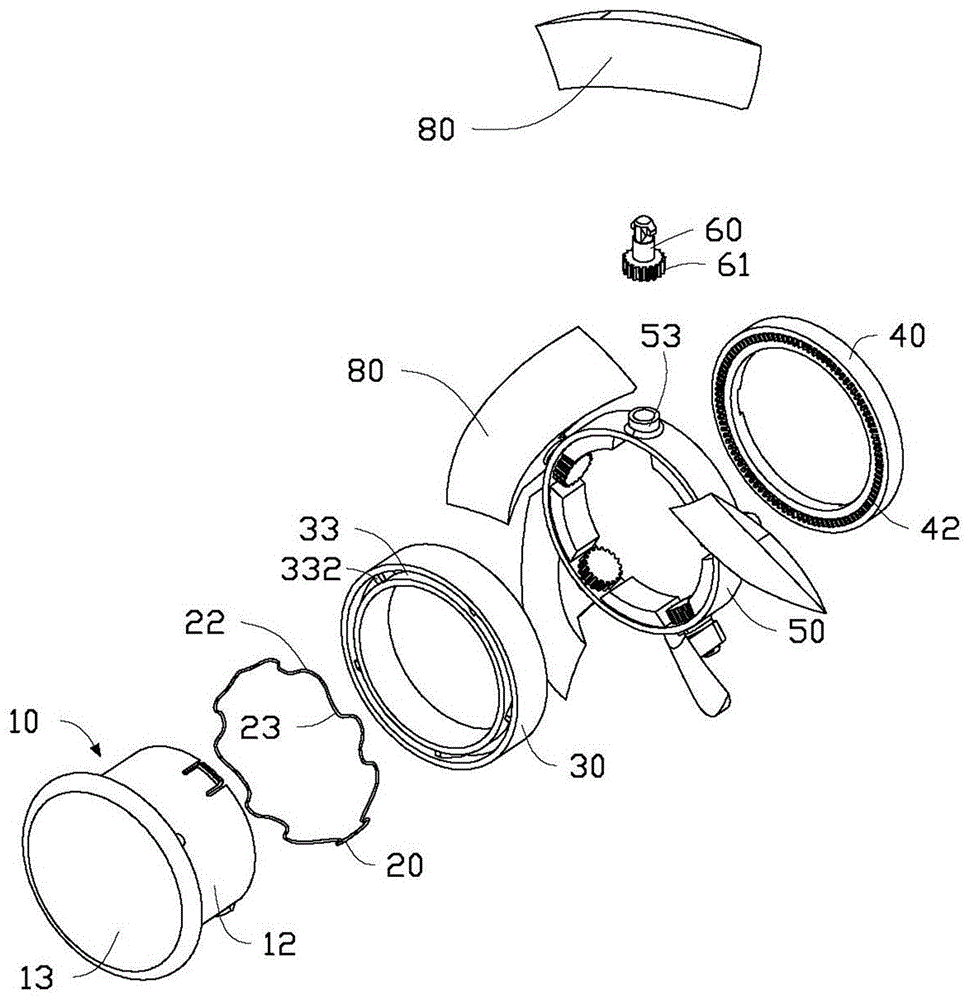

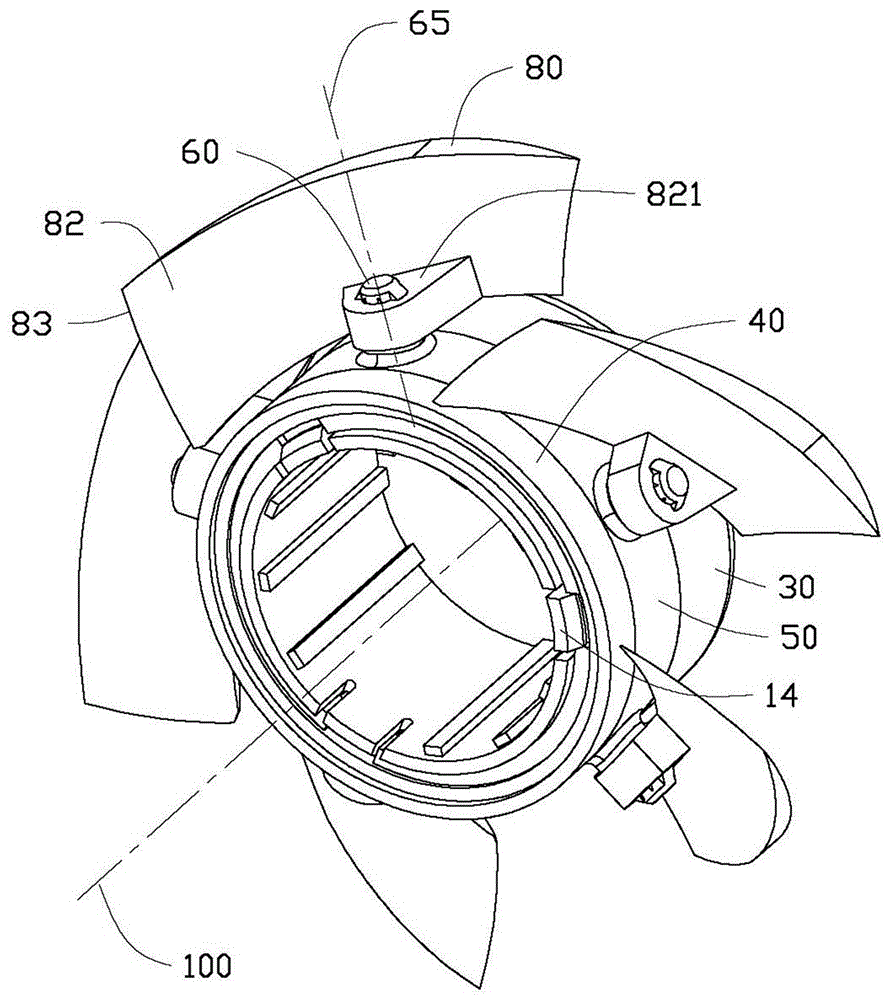

[0015] Please refer to figure 1 A preferred embodiment of the fan of the present invention includes a hub 10 , an elastic member 20 , a transmission ring 30 , a retaining ring 40 , a mounting ring 50 , a number of shafts 60 and a number of blades 80 .

[0016] The hub 10 includes a cylindrical body 12 and an annular end plate 13 disposed at one end of the body 12 . A plurality of fixing blocks 132 extending around the main body 12 are equidistantly extended from the end plate 13 toward the main body 12 . A plurality of hooks 14 are disposed at an end of the main body 12 away from the end plate 13 .

[0017] Please also refer to Figure 5 , the elastic member 20 is roughly ring-shaped. A plurality of first connecting portions 22 on the front side and second connecting portions 23 on the rear side protrude alternately from the elastic member 20 forward and backward. The first connecting portion 22 of the elastic member 20 is fixed to the fixing block 132 of the end plate 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com