Fireworks outer barrel mechanically molded by hydraulic mold at high temperature and manufacturing process of fireworks outer barrel

A high-temperature molding and mold technology, which is applied in pyrotechnics, weapon types, firecrackers, etc., can solve problems such as low production efficiency, polluting the environment, and unsafe conditions such as easy-to-explode cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

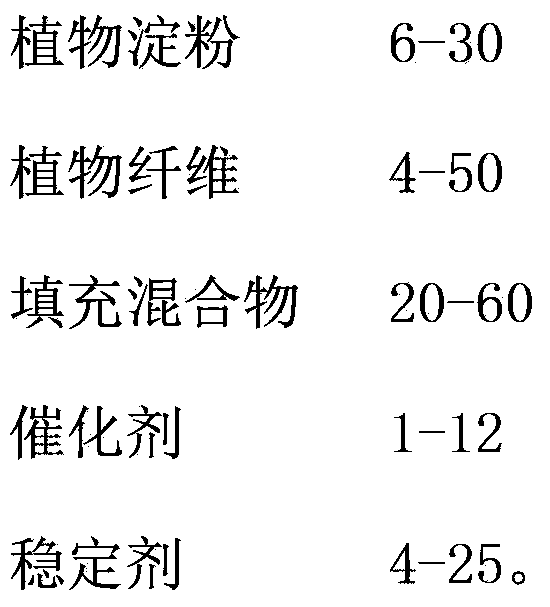

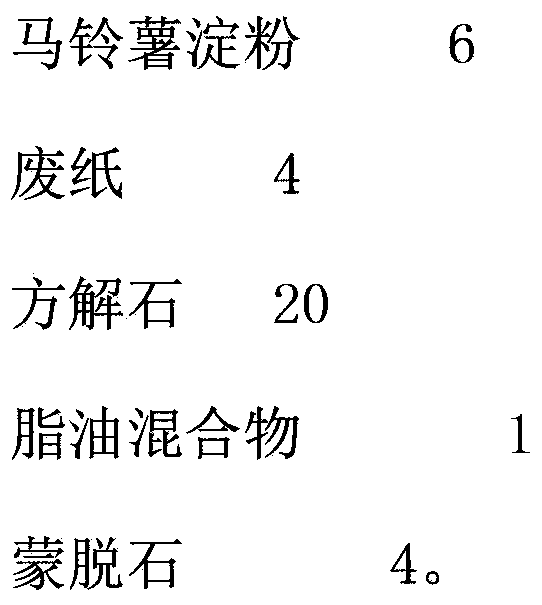

[0020] Mix the following ingredients (unit: kg)

[0021]

[0022] The above mixed raw materials are processed by the following steps to obtain the outer cylinder of fireworks formed by mechanized hydraulic mold at high temperature:

[0023] The first step: mixing ingredients: use a mixing machine to mix the raw materials, and then use a mixer to add an appropriate amount of normal temperature boiling water to stir;

[0024] The second step: high-temperature hydraulic mold forming: according to the first step and the prepared raw materials, pour the material into the hydraulic mold cavity of the hydraulic press with the material distribution plate, and the hydraulic press is closed. At the same time, the heat-conducting oil furnace sends the heat-conducting oil into the hydraulic press mold. Circulating heating, so that the temperature inside the mold is 120-320 degrees, until no water vapor emerges from the outside of the mold, and finally the hydraulic press opens the mold...

Embodiment 2

[0026] Mix the following ingredients (unit: kg)

[0027]

[0028] The above mixed raw materials are processed by the following steps to obtain the outer cylinder of fireworks formed by mechanized hydraulic mold at high temperature:

[0029] The first step: mixing ingredients: use a mixing machine to mix the raw materials, and then use a mixer to add an appropriate amount of normal temperature boiling water to stir;

[0030] The second step: high-temperature hydraulic mold forming: according to the first step and the prepared raw materials, pour the material into the hydraulic mold cavity of the hydraulic press with the material distribution plate, and the hydraulic press is closed. At the same time, the heat-conducting oil furnace sends the heat-conducting oil into the hydraulic press mold. Circulating heating, so that the temperature inside the mold is 120-320 degrees, until no water vapor emerges from the outside of the mold, and finally the hydraulic press opens the mold...

Embodiment 3

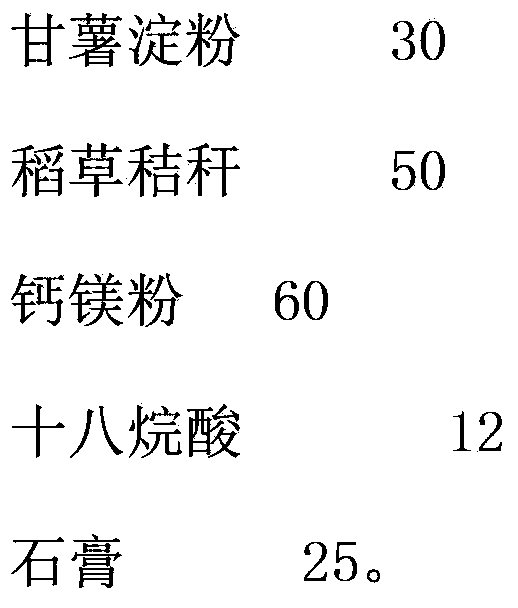

[0032] Mix the following ingredients (unit: kg)

[0033]

[0034] The above mixed raw materials are processed by the following steps to obtain the outer cylinder of fireworks formed by mechanized hydraulic mold at high temperature:

[0035] The first step: mixing ingredients: use a mixing machine to mix the raw materials, and then use a mixer to add an appropriate amount of normal temperature boiling water to stir;

[0036] The second step: high-temperature hydraulic mold forming: according to the first step and the prepared raw materials, pour the material into the hydraulic mold cavity of the hydraulic press with the material distribution plate, and the hydraulic press is closed. At the same time, the heat-conducting oil furnace sends the heat-conducting oil into the hydraulic press mold. Circulating heating, so that the temperature inside the mold is 120-320 degrees, until no water vapor emerges from the outside of the mold, and finally the hydraulic press opens the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com