Electric connector and method for installing same on substrate

A technology for electrical connectors and installation directions, which is applied in the direction of connection, connection part protection grounding/shielding device, fixed connection, etc., which can solve the problems of increasing the cost of the shielding part, failing to achieve electrical connection, and increasing the thickness of the shielding part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Preferred embodiments according to the present invention are described below with reference to the accompanying drawings.

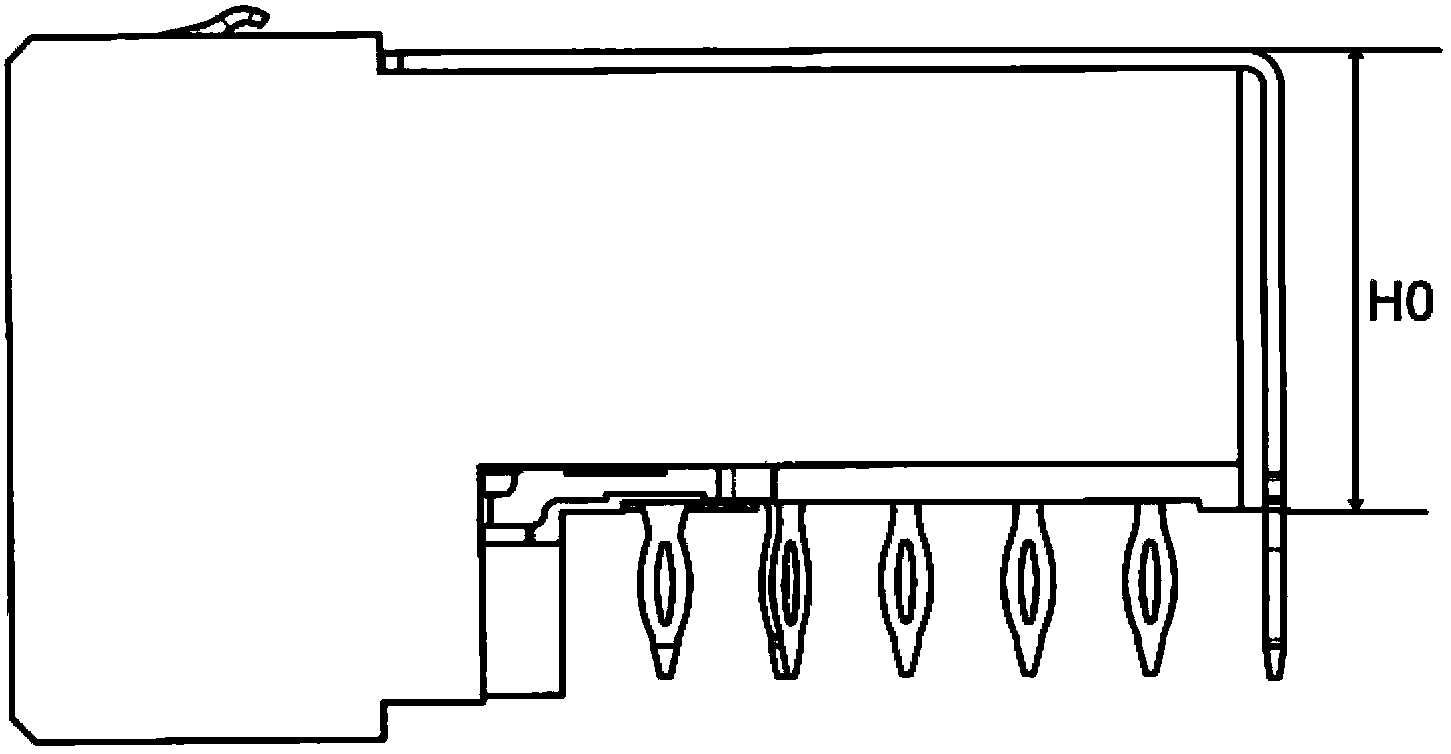

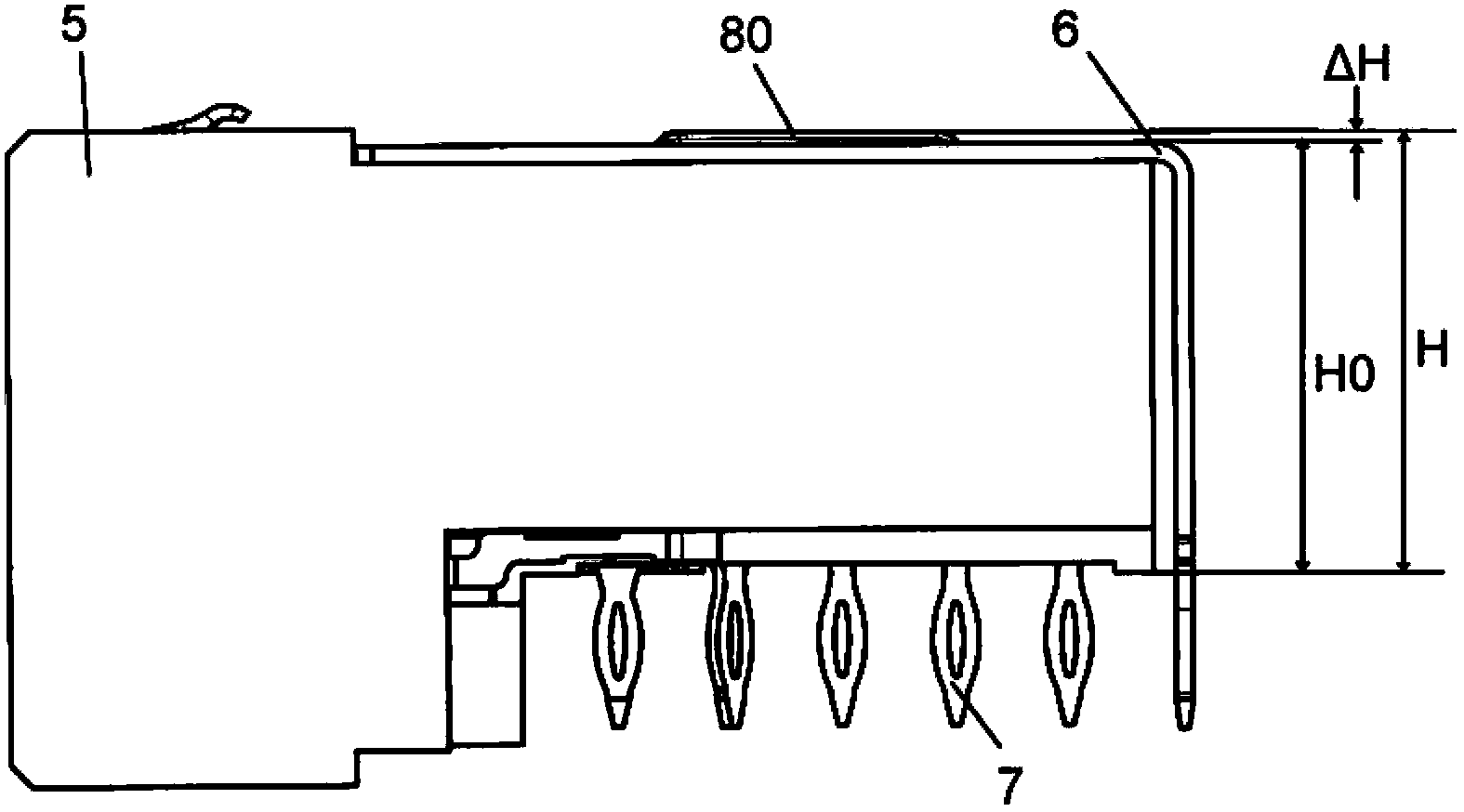

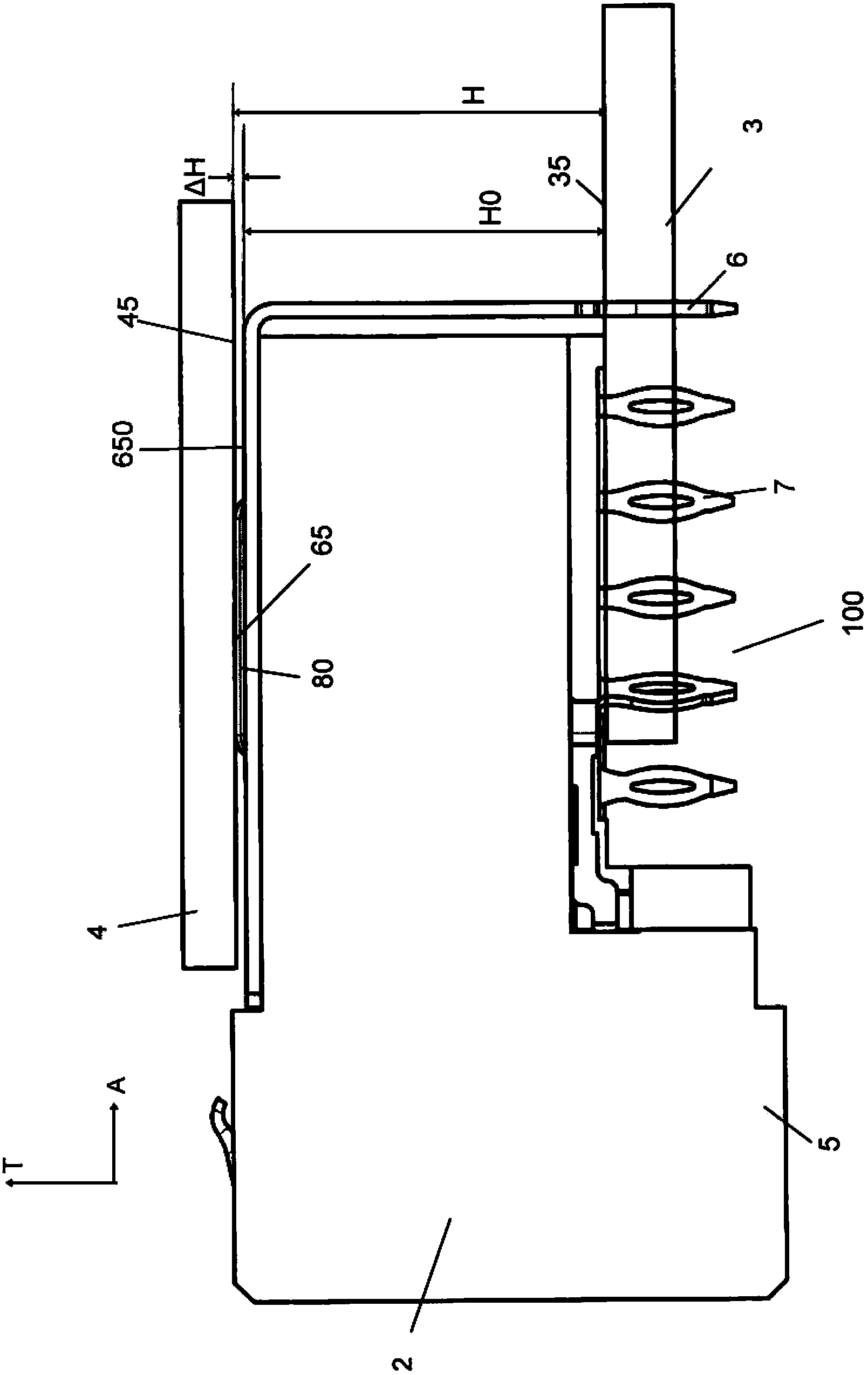

[0042] refer to figure 2 , shows an electrical connector system 100 comprising an electrical connector 2 and a substrate, which may be provided, for example, as a printed circuit board (PCB) 3 , figure 2 A state in which the electrical connector 2 is mounted to the printed circuit board 3 is shown in . The figure also shows a pressing tool 4 for installing the electrical connector 2 on the printed circuit board 3 .

[0043] In this embodiment, the electrical connector 2 is a right-angle electrical connector. image 3 show figure 2 A perspective view of the electrical connector 2 of the electrical connector system 100. The electrical connector 2 defines a mating interface 22 and a mounting interface 24 . The mating interface 22 is configured to cooperate with a mating electrical component, such as another electrical connector or other electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com