Gas mixer and gas mixing system

A gas mixer and gas technology, applied in the direction of gas and gas/steam mixing, fluid mixer, mixer, etc., can solve the problems of poor overall efficiency and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

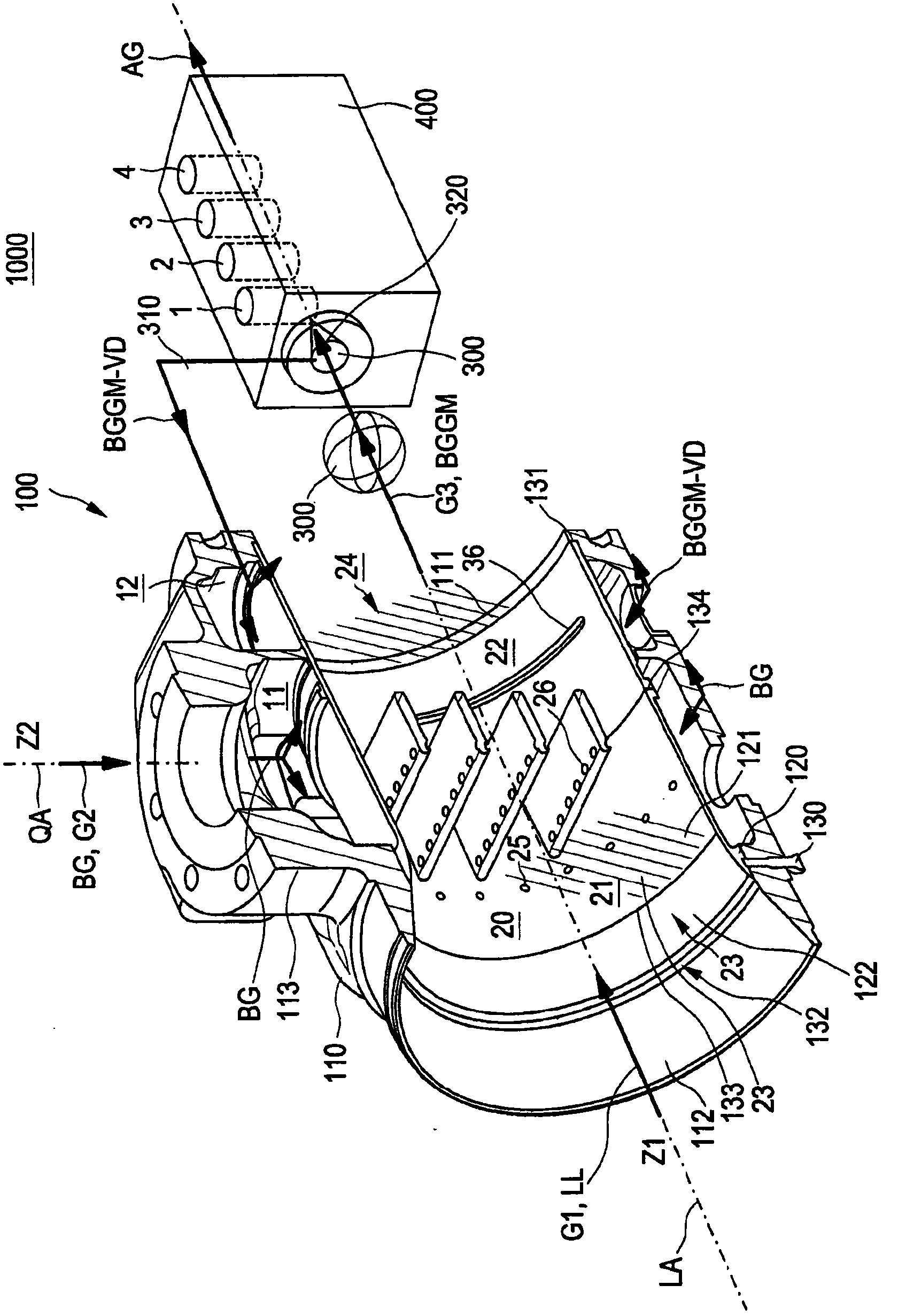

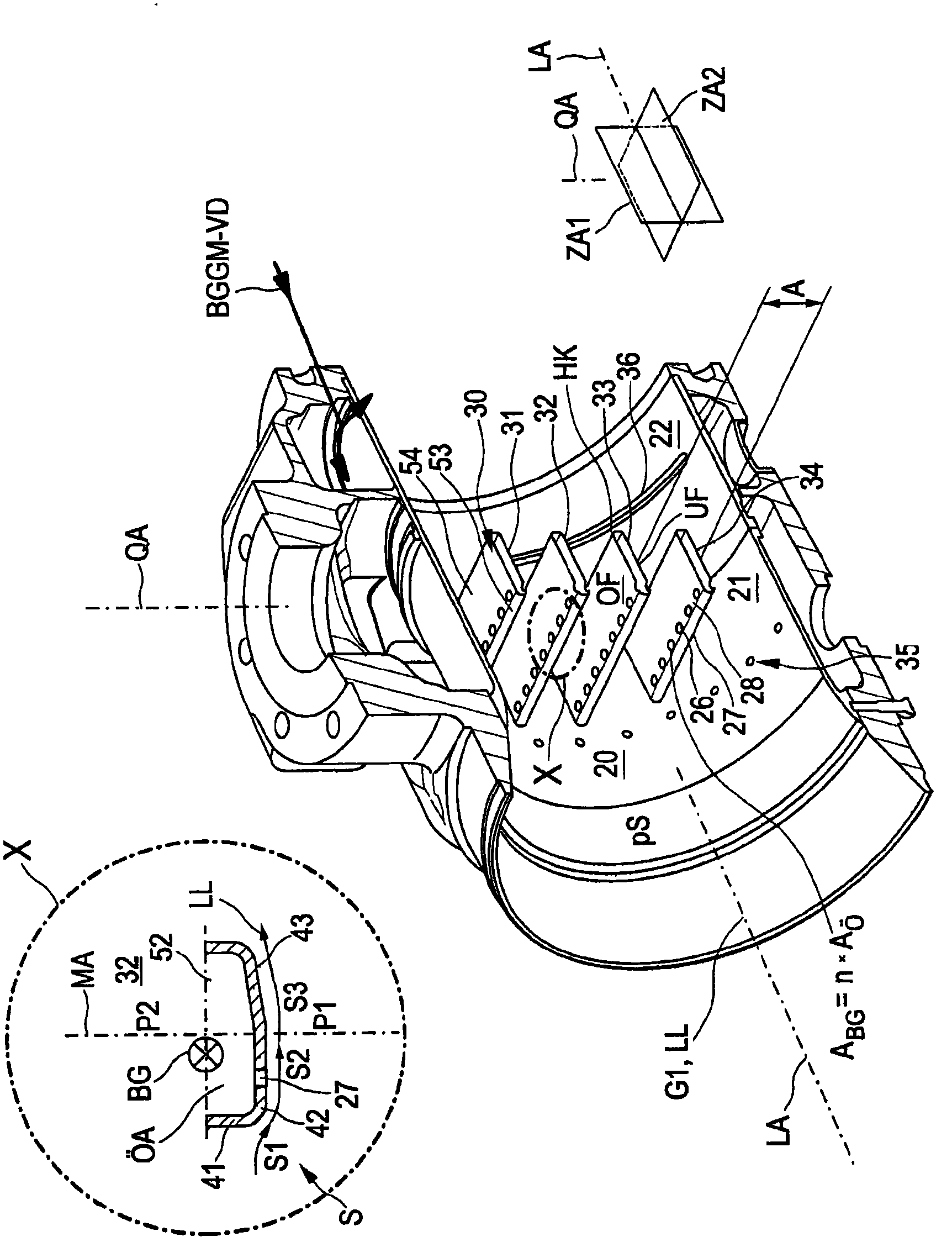

[0035] figure 1 Shown is a gas mixing system 1000 with a gas mixer 100 for mixing a first gas G1 - charge air LL in this embodiment and a second gas G2 - in this embodiment combustible gas LL, for a gas engine 400 Gas BG. The gas mixture G3 formed by the first gas G1 and the second gas G2 - in this embodiment a combustible gas mixture BGGM - is supplied to a compressor 300 and finally in compressed form to an internal combustion engine which in this embodiment A gas engine 400 with cylinders 1 , 2 , 3 , 4 is shown symbolically in FIG. Combustible gas mixture BGGM combusted for work in gas engine 400 is discharged as exhaust gas AG into an exhaust gas recirculation system and, if necessary, into the environment via an exhaust gas aftertreatment system, which will not be explained further. In this embodiment shown, the gas mixer 100 is incorporated into a high pressure recirculation system 310 . The pressure regulator 320 serves in this embodiment to power the gas engine 400 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com