Exhaust gas feed device for an internal combustion engine

A technology of exhaust gas introduction and internal combustion engine, applied in the direction of internal combustion piston engine, exhaust gas recirculation, combustion engine, etc., can solve the problems of high pressure loss, no mixing, exhaust gas pipeline pulsation and difficult adjustment of pressure difference, etc. Effects of reduced space, reduced temperature spikes, simple installability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

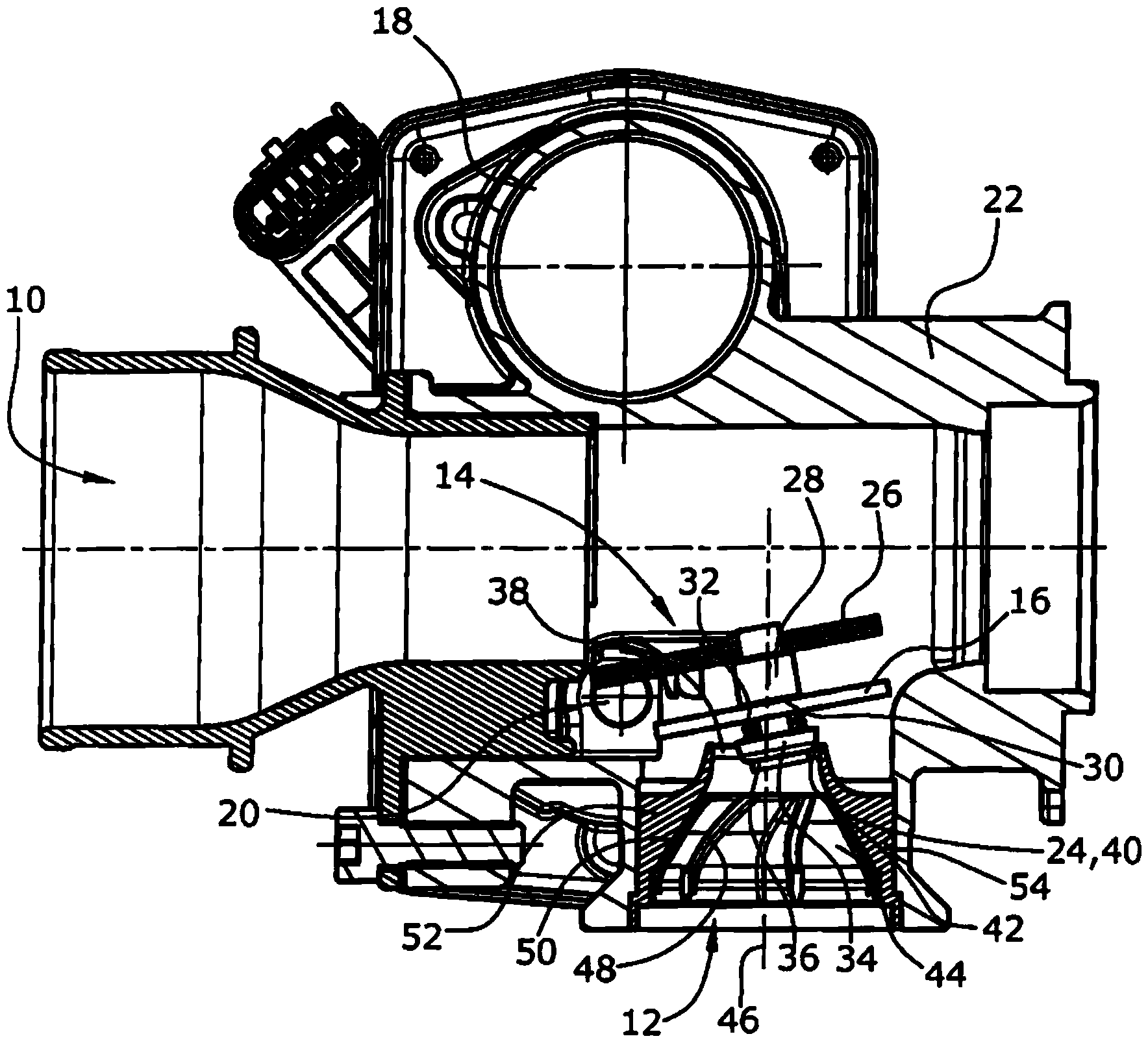

[0021] The exhaust gas introduction device according to the present invention includes an air suction passage 10 in which air used for combustion in an internal combustion engine is sucked in the direction of the compressor of the turbocharger through a filter on the upstream side of the flow not shown. The returned exhaust gas is introduced into the air suction passage 10 in the low-pressure exhaust gas return part before the compressor.

[0022] This is done through the exhaust gas return passage 12, which in this embodiment opens into the air suction passage 10 at right angles to the air suction passage 10. The amount of returned exhaust gas is adjusted by an exhaust gas return valve 14 whose regulating body is formed by an eccentrically supported plate 16 in this embodiment.

[0023] The exhaust gas return valve 14 has an actuator 18 in the form of an electric motor followed by a transmission through which a shaft 20 used as a rotating shaft rotates. This shaft 20 is supported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com