A garden cutting robot

A robot and gardening technology, applied in the field of robotics, can solve the problems of no robot, loss of aesthetic feeling, uniform appearance of garden plants, etc., and achieve the effect of improving efficiency, convenient and effective use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

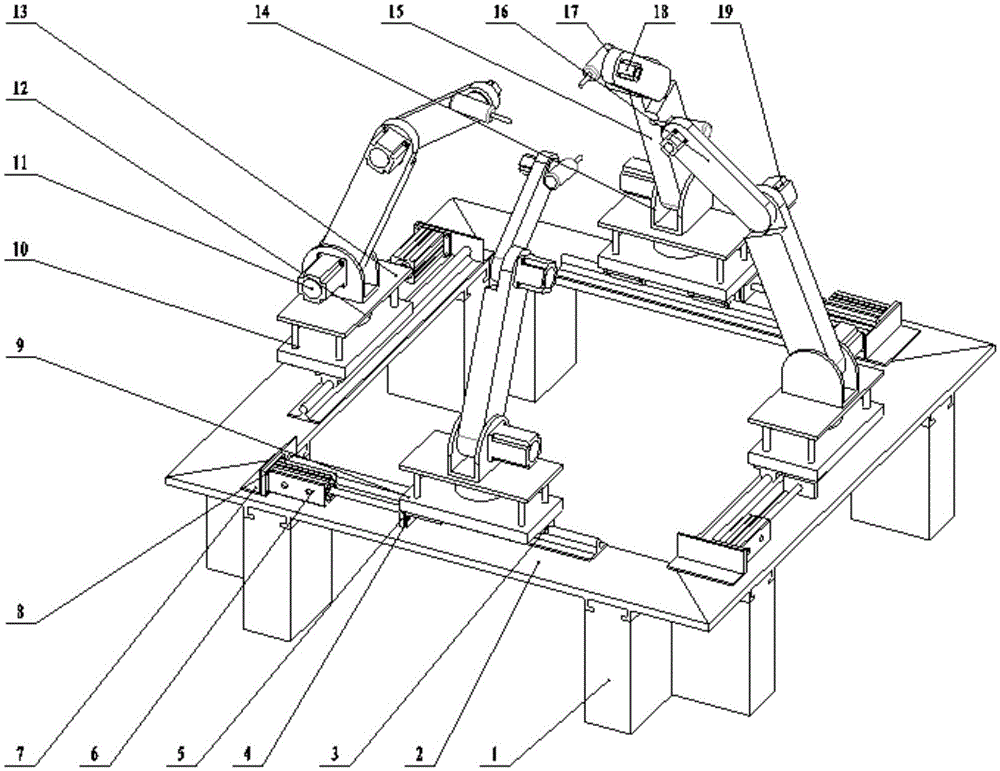

[0008] A garden cutting robot is composed of a bottom column 1, a mounting plate 2, a slider 3, a cylinder pushing plate 4, a cylinder pushing plate 5, a cylinder 6, a cylinder mounting plate 7, a slide rail 8, a sliding plate 9, a support column 10, Double splint motor 11, rotating motor 12, small fixed plate 13, double splint 14, large arm plate 15, small arm plate 16, water cutting head 17, small arm motor 18 and large arm motor 19 are characterized in that: The above-mentioned mounting plate 2 is equipped with 2 base columns 1, 4 mounting plates 2 can be connected together, the slider 3 can move on the slide rail 8, the slide rail 8 is fixed on the mounting plate 2, and the cylinder pushing plate 4 is fixed on the On the cylinder push plate 5, the cylinder push plate 5 is connected with the cylinder 6, the cylinder 6 is fixed on the cylinder mounting plate 7, the sliding plate 9 is installed on the slider 3 and the cylinder push plate 5, and the support column 10 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com