Zinc-alloy zipper

A zinc alloy, zipper technology, applied in clothing, fasteners, sliding fastener components, etc., can solve the problems of high resistance, easy damage, high cost of zippers, etc., and achieve the effects of low resistance, long life and reasonable product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

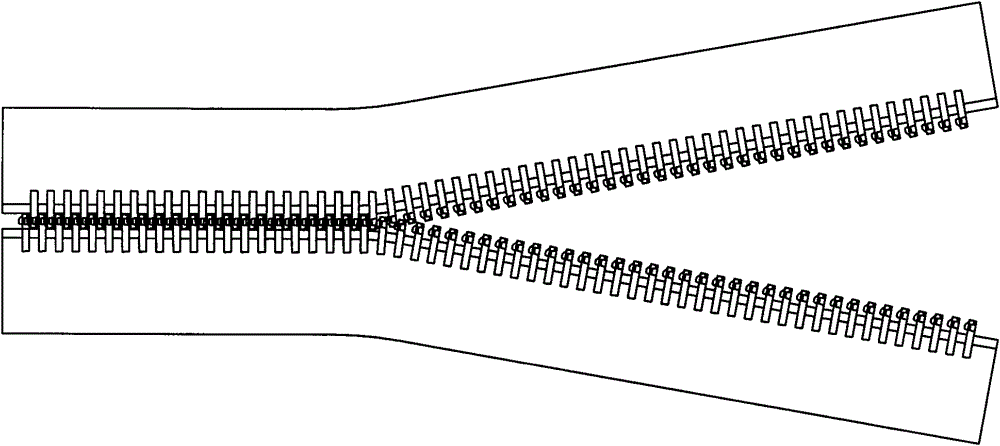

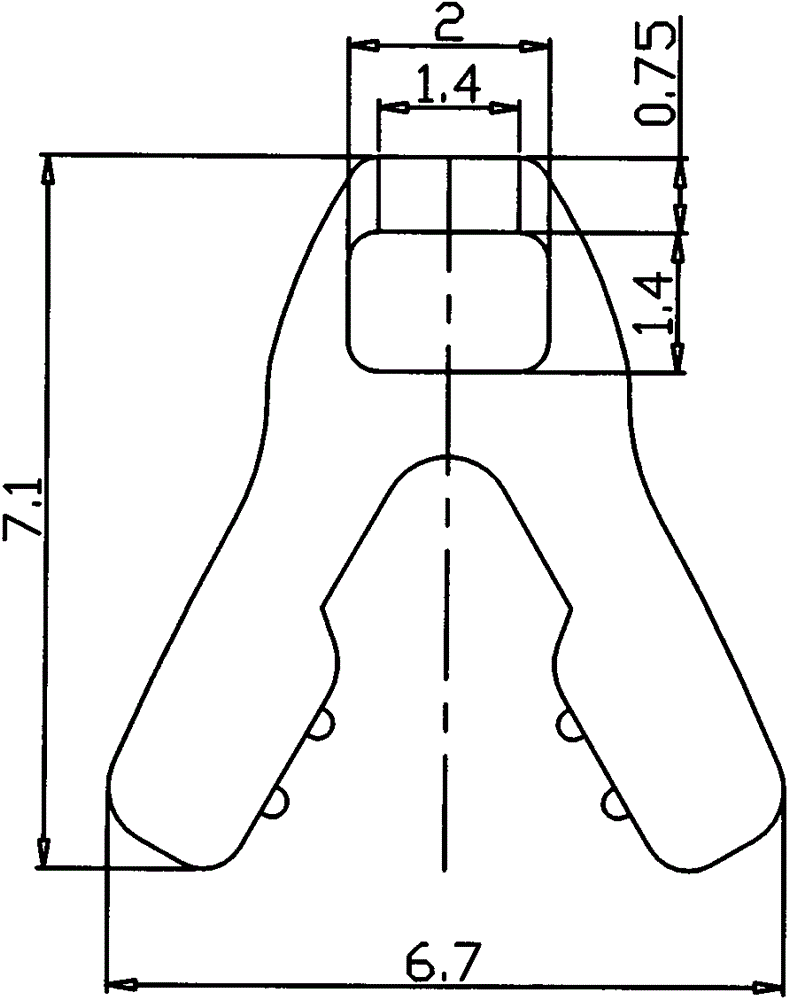

[0020] to combine Figure 1-10 , is a structural schematic diagram of an embodiment of a zinc alloy zipper of the present invention, including chain tooth rice grains and zipper cloth tapes. The chain tooth rice grains are formed by hot die-casting of zinc alloy materials, and after polishing and electroplating, they are attached by an automatic feeding machine A zipper is formed on the zipper tape; the chain teeth rice grains are European tooth type, corn type or Y tooth type; the chain tooth rice grains include an engaging end and a mounting end, and both ends are formed by one-time die-casting of zinc alloy material An integral structure, the chain tooth rice grains are 3-8mm long, 3-7mm wide, and 1-3mm thick.

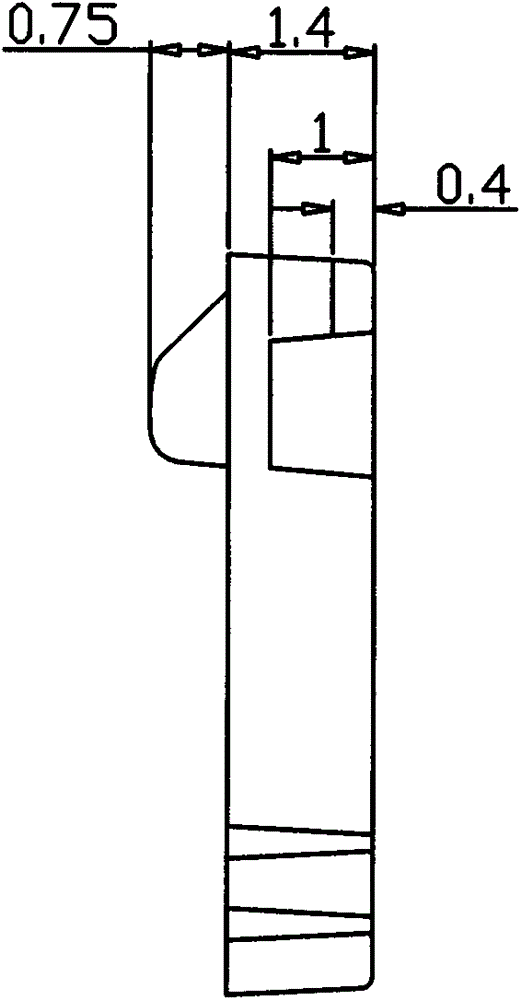

[0021] to combine Figure 2-4 , is a schematic diagram of the embodiment structure of the 5# European tooth type chain tooth rice grain of the zinc alloy slide fastener, including 3#, 5#, 8#, 10#, 12#, 15# specifications like this style.

[0022] to combine Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com