Smoothly operated compressor automatic discharging system

A technology of automatic unloading and pressing, which is applied in the directions of filtration and separation, separation methods, chemical instruments and methods, etc., to achieve smooth movement, improve production efficiency, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in conjunction with the following examples.

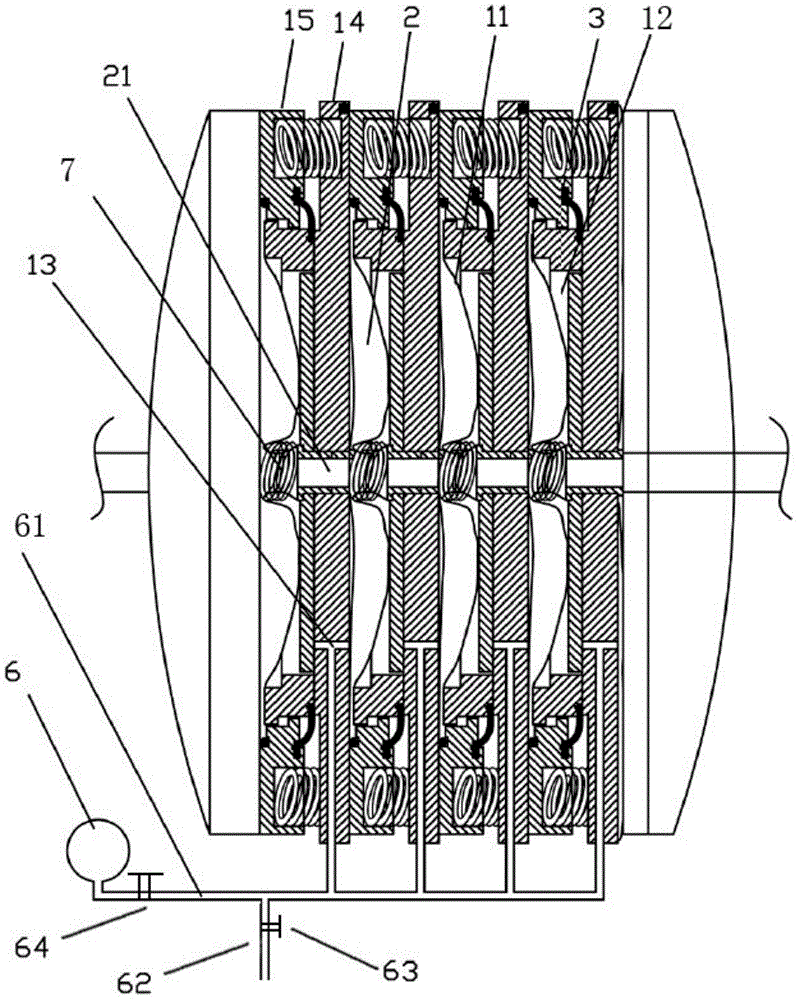

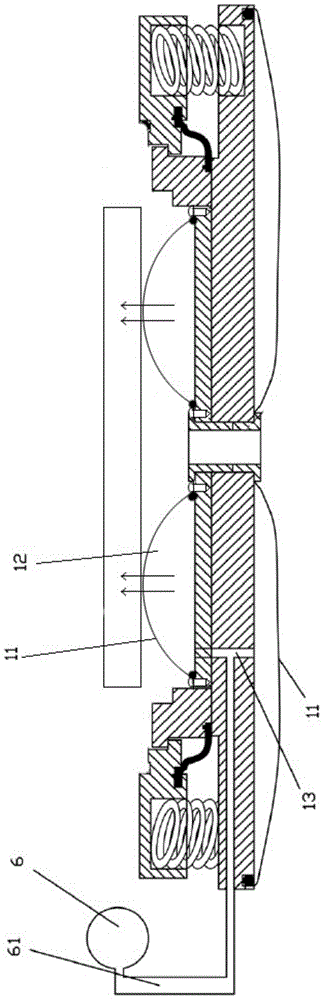

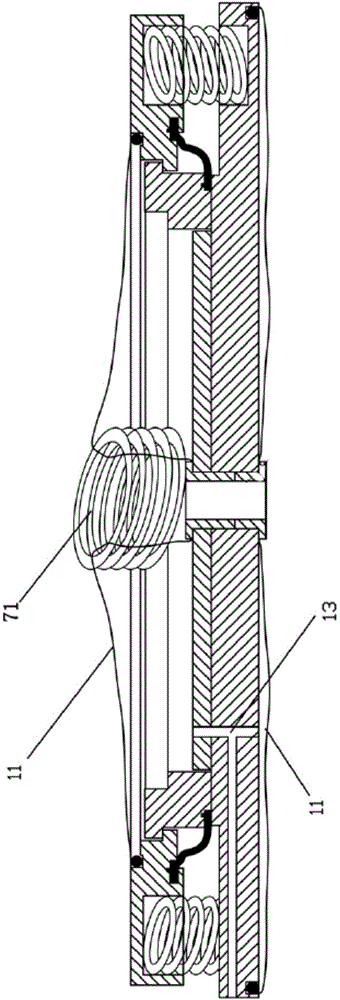

[0027] Such as figure 1 As shown, a smooth-running automatic unloading system for presses includes two or more filter plate groups that are sequentially contacted and connected. A filter cloth 11 is provided on the front of the filter plate groups, and a filter cloth 11 is provided between the two filter plate groups that are in contact with each other. There is a cavity, and the filter cloth 11 divides the cavity into two parts, wherein the filter cloth 11 and the back of the previous filter plate group form the material cavity 2, the filter cloth 11 and the filter plate group to which it belongs form the filtrate cavity 12, and the filter plate group A water outlet hole 13 for discharging filtrate is provided.

[0028] The filter plate group is equipped with an automatic unloading system, which acts on the filter cloth 11 to make the filter cloth 11 bulge toward the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com