A lower horizontal plate swivel bending clapping flat mold device

A mold and horizontal plate technology, which is applied in the field of the lower horizontal plate rotating, bending and flattening mold device, can solve the problems of cumbersome completion, inconvenient loading and unloading of the lower horizontal plate, too many processes, etc., and achieves simple and convenient operation, convenient and quick disassembly, and improved machining accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

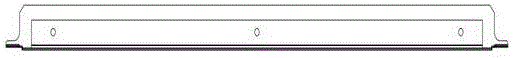

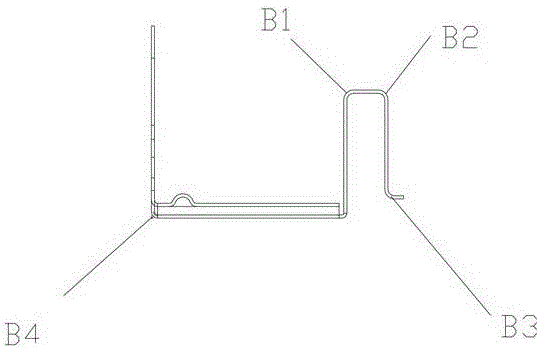

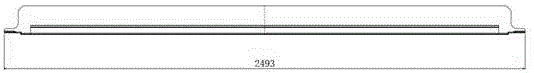

[0031] Figure 1 to Figure 9Shown is the embodiment of the flat mold device of the lower transverse plate rotary bending of the present invention. The mold device is installed on the punching machine. The mold device includes a first module 1 and a second module 2. The first module 1 is provided with a first driving module 11; The flattening module 22 for flattening the lower horizontal plate, the second drive module 23 for driving the movement of the flattening module 22; the punch press drives the first module 1 to move in the direction of covering the second module 2, driving the first driving module 11 Move to contact with the second driving module 23, the second driving module 23 drives the leveling module 22 to contact the lower horizontal plate and level the lower horizontal plate. Specifically, the first module 1 is provided with a pressing member 12 , the pressing member 12 cooperates with the fixing member 21 , and the pressing member 12 is provided with a first ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com