Electric valve

A technology of electric valves and needle valves, which is applied in the direction of valve lifts, valve details, valve devices, etc., can solve the problems of high cost, hindering the work of the valve body, and the inability to use the motor drive torque, etc., to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

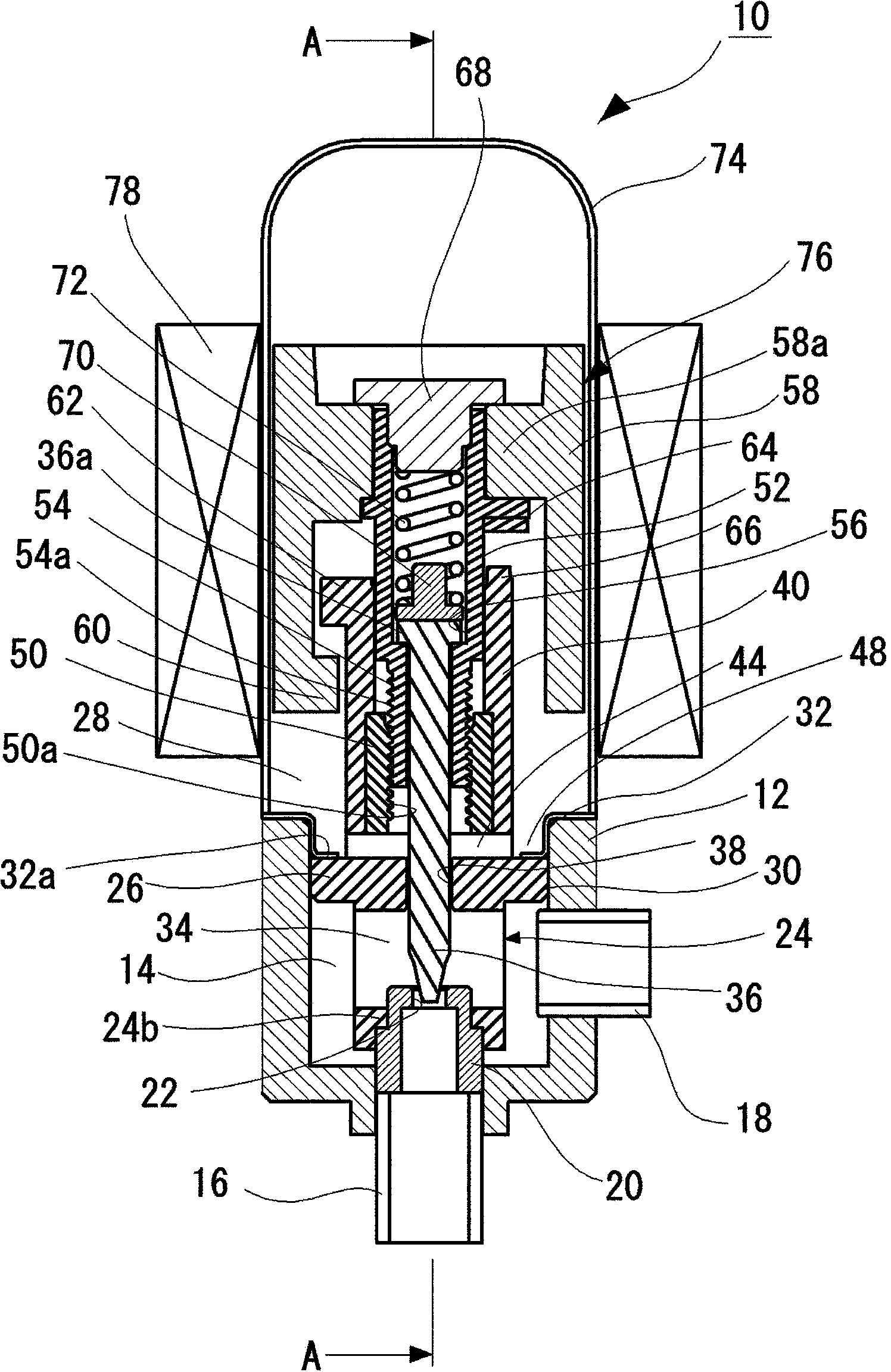

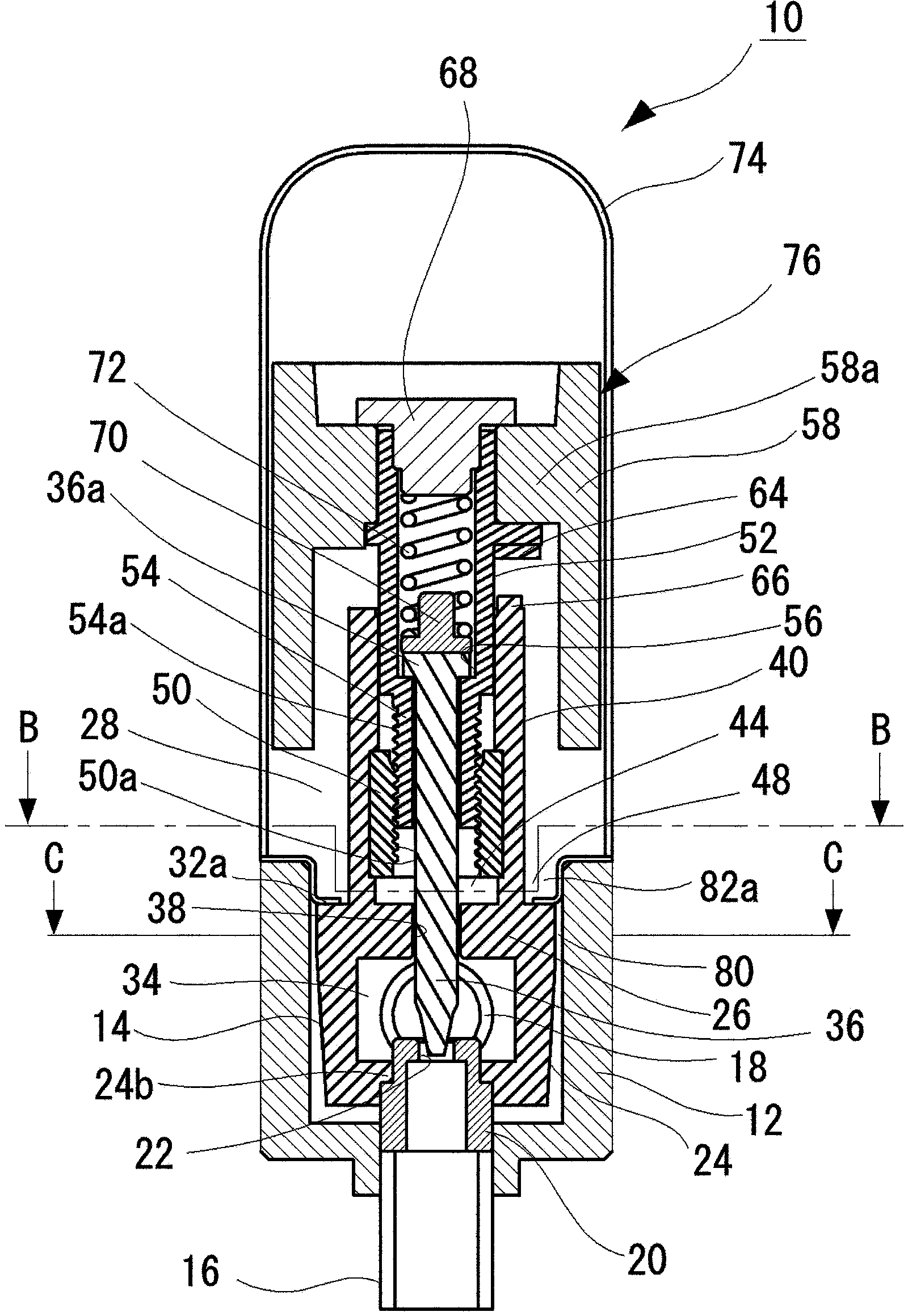

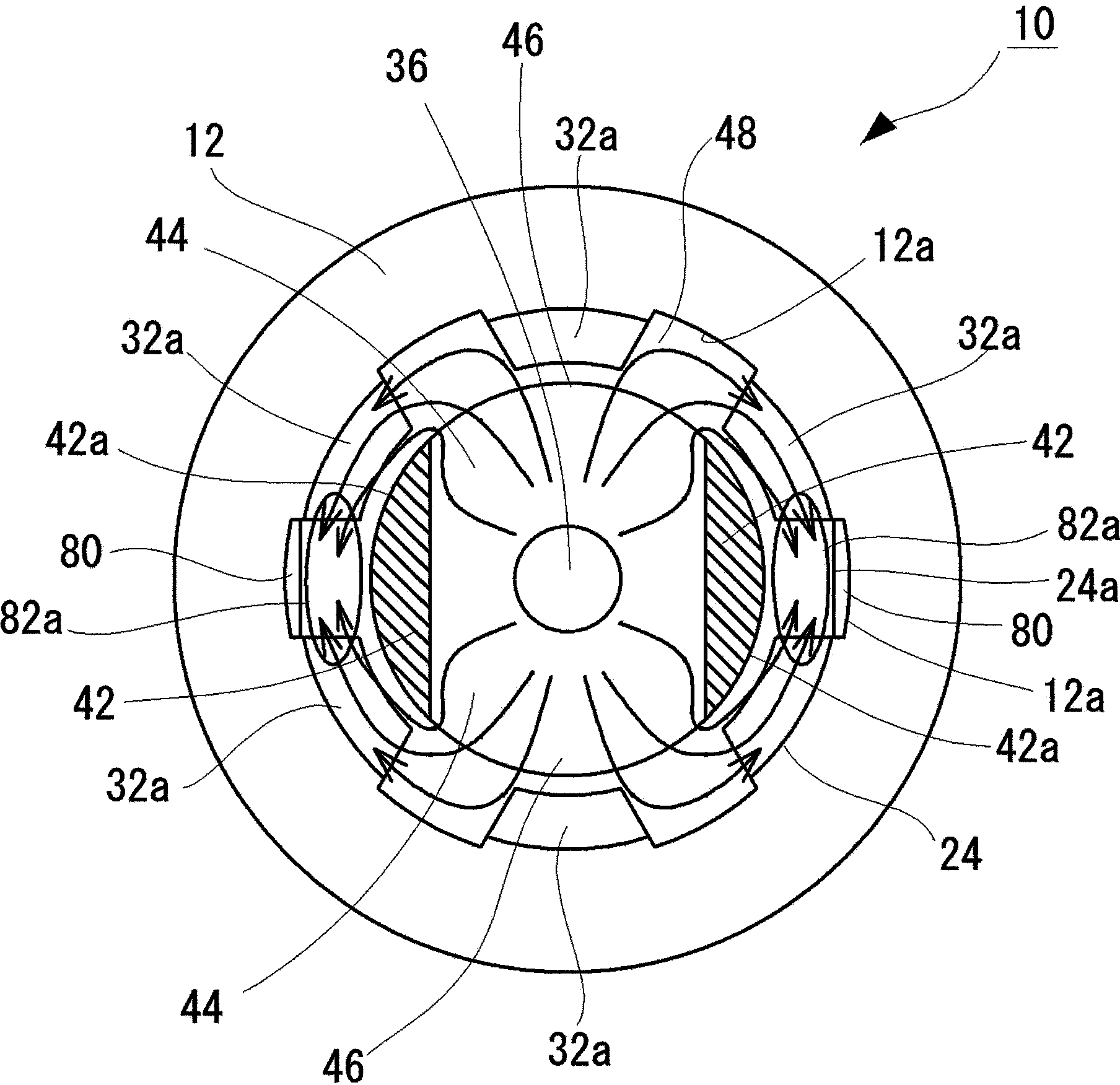

[0054] figure 1 It is a longitudinal sectional view of the valve opening state of the electric valve of the present invention, figure 2 yes figure 1 A longitudinal sectional view of line A-A, image 3 yes figure 2 A sectional view of the B-B line, Figure 4 yes figure 2 A cross-sectional view of line C-C, Figure 5 is closed valve state, and figure 1 The same longitudinal section view.

[0055] exist Figure 1 to Figure 5 In , the whole of symbol 10 represents the electric valve of the present invention.

[0056] Such as Figure 1 ~ Figure 2 As shown, the electric valve 10 of the present invention has a valve body 12 in which a valve chamber 14 is formed. Furthermore, a first pipe member 16 serving as an inlet joint and a second pipe member 18 serving as an outlet joint are attached so as to communicate with the valve chamber 14 .

[0057] In addition, a valve seat 20 is fixed to the valve main body 12 on the upper portion of the first piping member 16 , and a va...

Embodiment 2

[0092] Image 6 is another embodiment of the electric valve of the present invention, and image 3 The same cutaway view.

[0093] The configuration of the electric valve 10 of this embodiment is basically the same as the configuration shown in Embodiment 1, and the same components are given the same reference numerals, and detailed description thereof will be omitted.

[0094] In the electric valve 10 of this embodiment, as Image 6 As shown, four horizontal flow expansion passages 44 are formed on the guide portion 40 of the guide sleeve 24 .

[0095] On the other hand, four opposing communication outlets 46 are formed, and four deposition portions 82 of the outer annular flow path 48 where the fluids flowing in the outer annular flow path 48 merge with each other and the flow velocity is reduced are formed. Four vertical flow paths 80 are formed on the portion 82 .

[0096] Also in the motorized valve 10 of this embodiment, the same effect as that of the motorized valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com