Transfer and sorting conveyor

A conveyor belt and sorting technology, applied in the field of conveyor belts, can solve problems such as difficult inspection and adjustment, inability to reduce the installation interval of sliders, timing deviation between sliders of switching mechanism and sorting signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

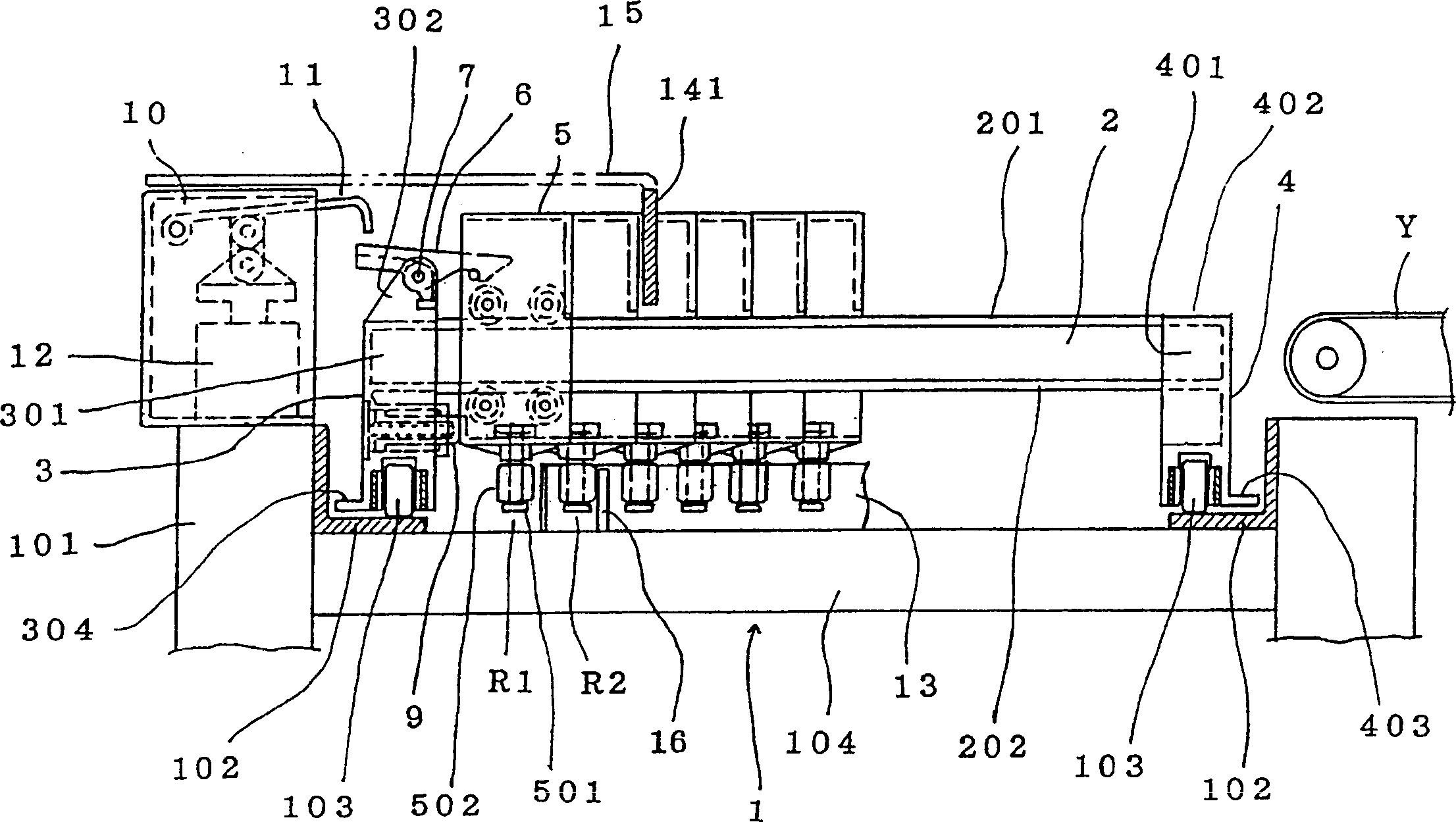

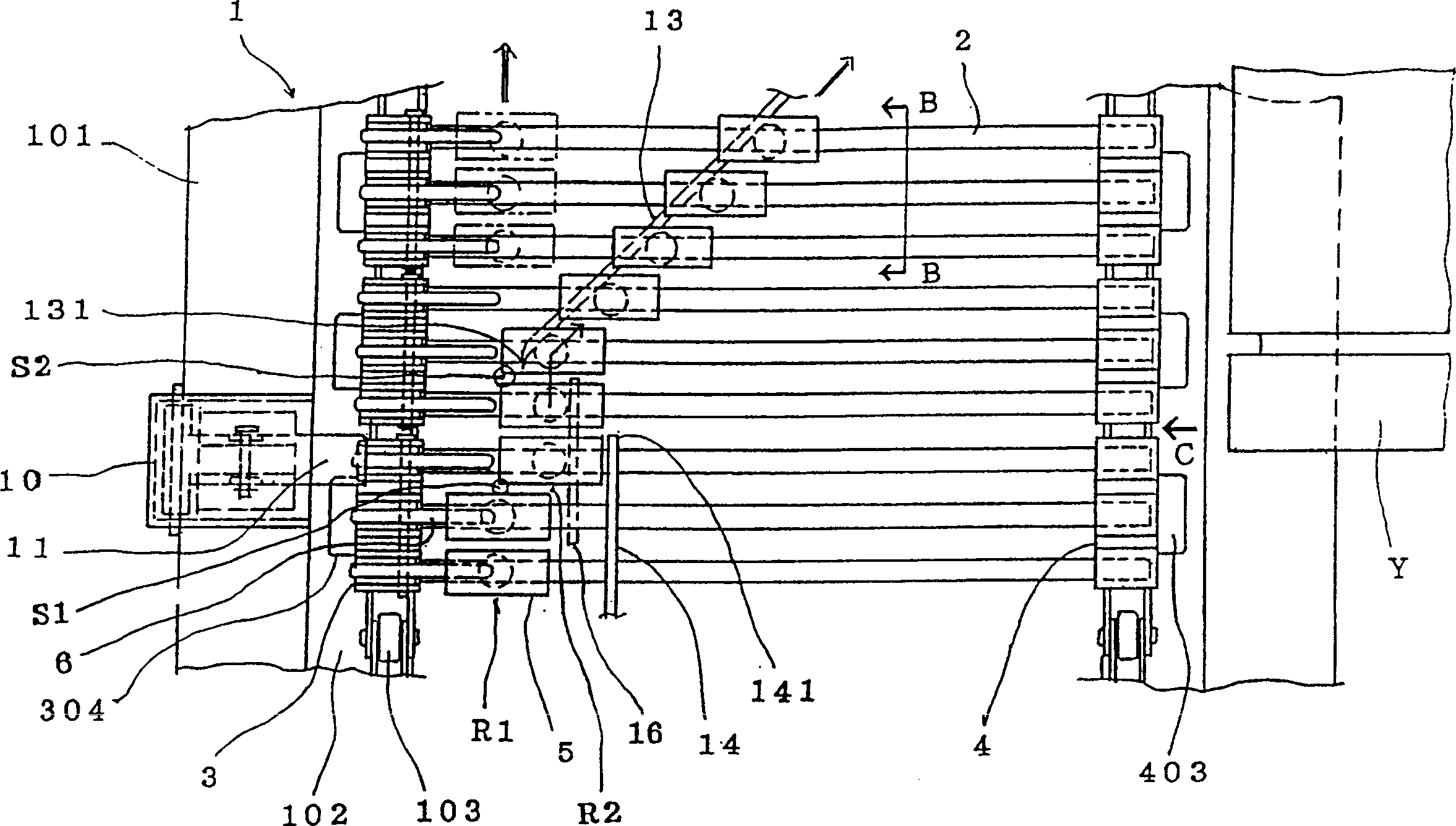

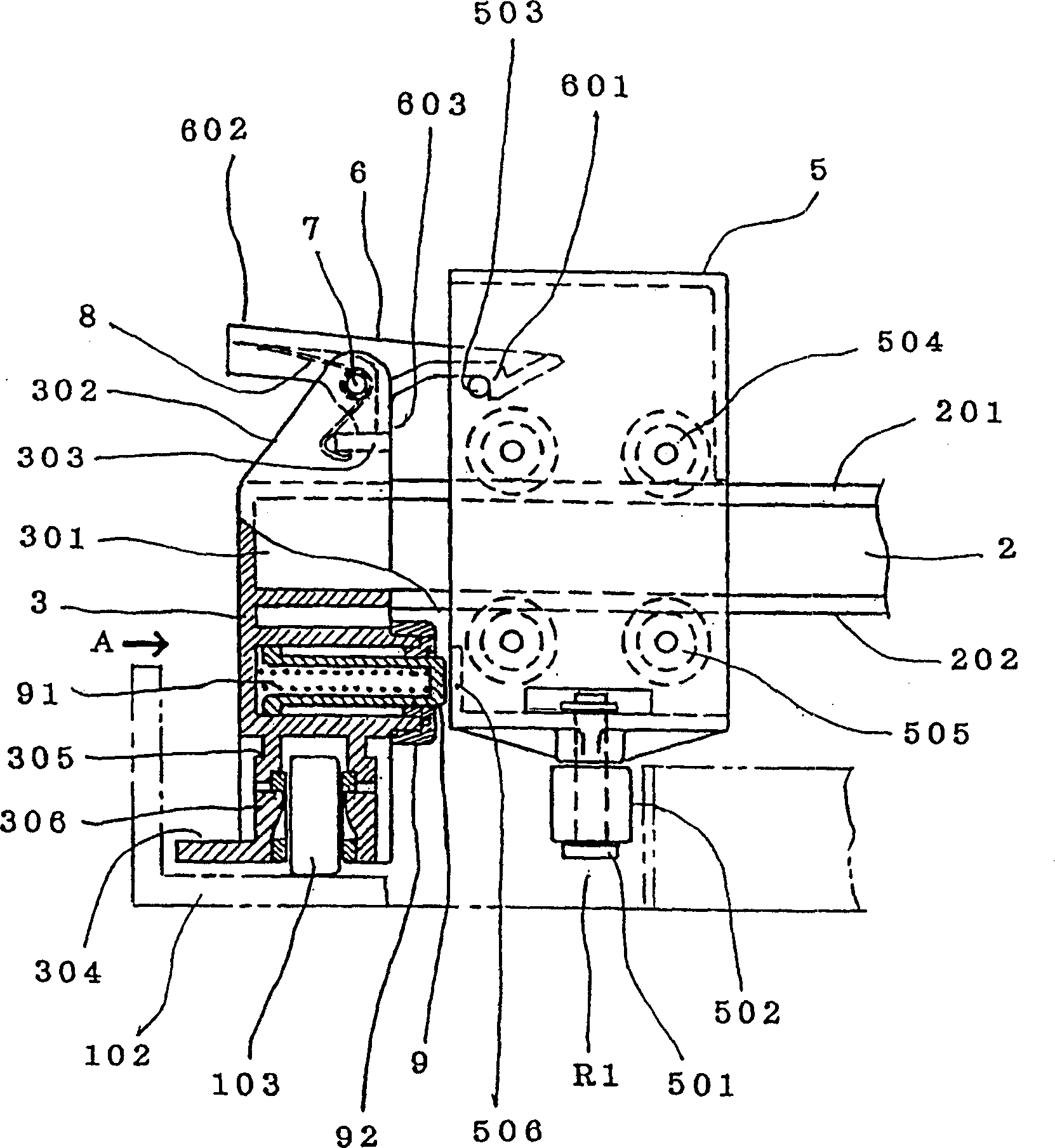

[0039] Below, the embodiments will be described in conjunction with the accompanying drawings. figure 1 is a sectional view of the main part of the sorting conveyor belt, figure 2 is the top view of its main parts, and the detailed structure is shown in Figure 3 ~ Figure 8 .

[0040] In the figure, as a conveyor belt 1, a closed conveyor belt chain 103 is arranged on a chain rail 102 arranged on the inner side of both sides of a frame 101, and the conveying surface forming members 2 are arranged in parallel between the conveyor belt chains 103, and the two ends pass through one side. The installation part 3 on the one side and the installation part 4 on the other side are respectively installed on the chains 103 on both sides.

[0041] Sliders 5 combined so as to be movable (hereinafter also referred to as lateral movement) in the longitudinal direction (hereinafter also referred to as the width direction of the conveyor belt) are respectively attached to each conveying su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com