Environment-friendly reclaimed rubber extruding equipment

A technology of extrusion equipment and reclaimed rubber, which is applied in the field of environmentally friendly reclaimed rubber extrusion equipment, can solve the problems of poor quality of waste rubber regeneration equipment, and achieve the effects of broad market development prospects, long service life and good fracture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

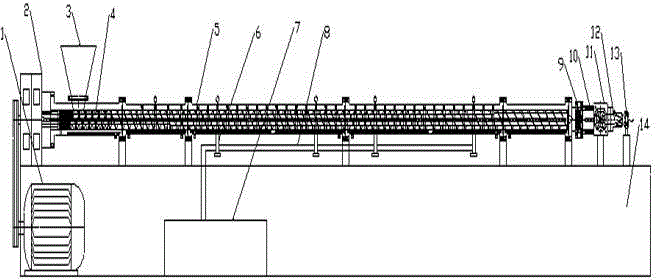

[0029] Environmentally friendly reclaimed rubber extrusion equipment, including motor 1, reduction box 2, hopper 3, feeding section 4, plasticizing recovery device 5, air release valve 6, waste recovery device 7, connecting pipe 8, filter 9, cooler 10. Extruder 11, discharger 12, tractor 13 and base 14, motor 1, reduction box 2 and waste recovery device 7 are installed on the base 14, motor 1 and reduction box 2 are connected, deceleration The box 2 is connected with the feeding section 4 to provide propulsion power. The feeding section 4 is provided with a hopper 3, and the right end of the feeding section 4 is connected to the plasticizing recovery device 5. The cooperation between the feeding section 4 and the plasticizing recovery device 5 is realized Feed and extrusion will not produce the disadvantage of insufficient raw material slipping and conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com