A method for manufacturing a carbon fiber composite material propeller by secondary molding

A technology of overmolding and composite materials, which is applied in the field of carbon fiber composite material propellers to achieve the effects of reasonable design, long life and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

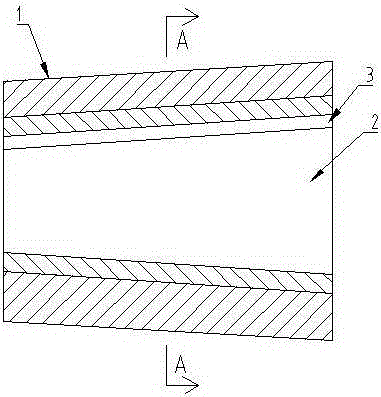

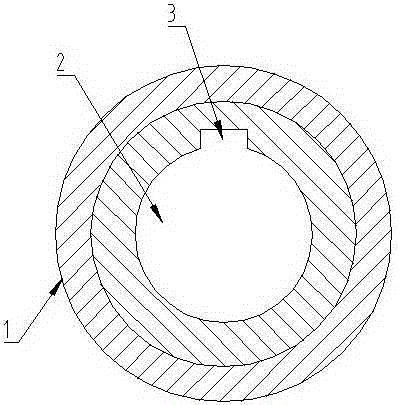

[0046] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

[0047] A method for manufacturing a carbon fiber composite propeller with secondary molding, the steps are as follows,

[0048] 1. Preparation:

[0049] 1.1 Selection and processing of molds:

[0050] 1.1.1 Selection of mold: The mold is divided into upper and lower molds, both of which are metal molds; the mold meets the following conditions: ① fully consider the fluidity of the resin in the mold, and reasonably set the injection port and exhaust port; ② the strength of the mold High, small deformation, accurate size;

[0051] 1.1.2 Mold treatment: first use a cloth of soft material to wipe off the dust and oil stains on the surface of the mold, and wax evenly on the surface of the clean mold for at least 2-4 times to facili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com