Overhead air conditioning unit with sand wind preventing function and for railway vehicle

A technology for rail vehicles and air-conditioning units, which is applied in the heating/cooling of railway vehicles, railway car body parts, and railway transportation, etc. problems, to achieve the effect of improving cooling effect, low cost, and improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

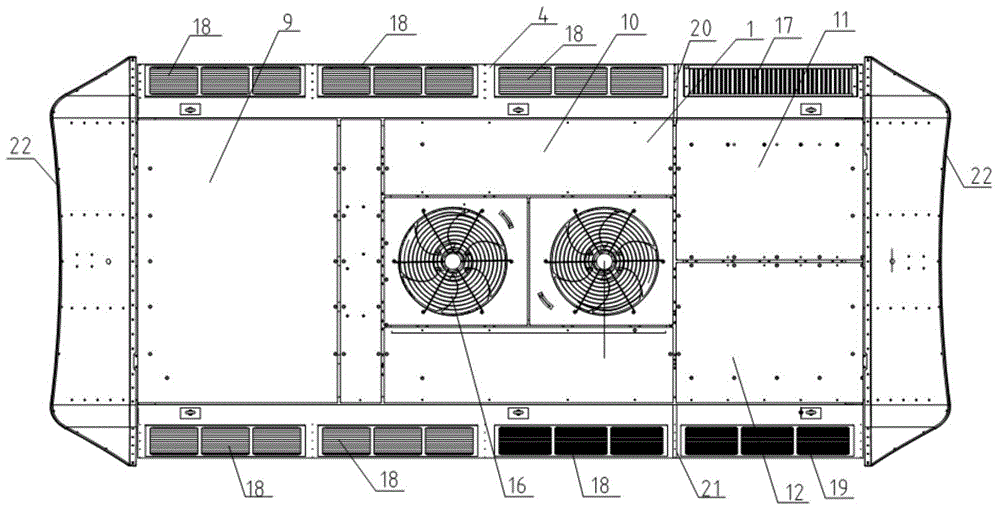

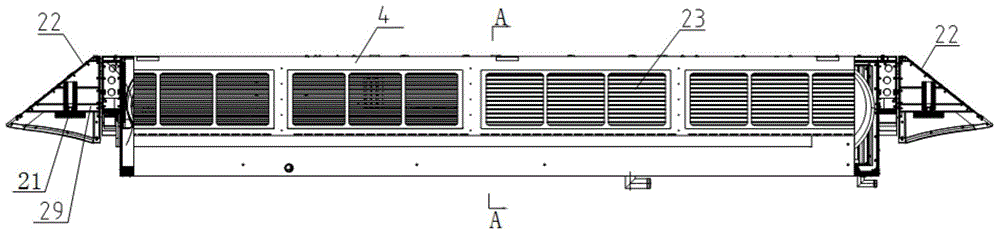

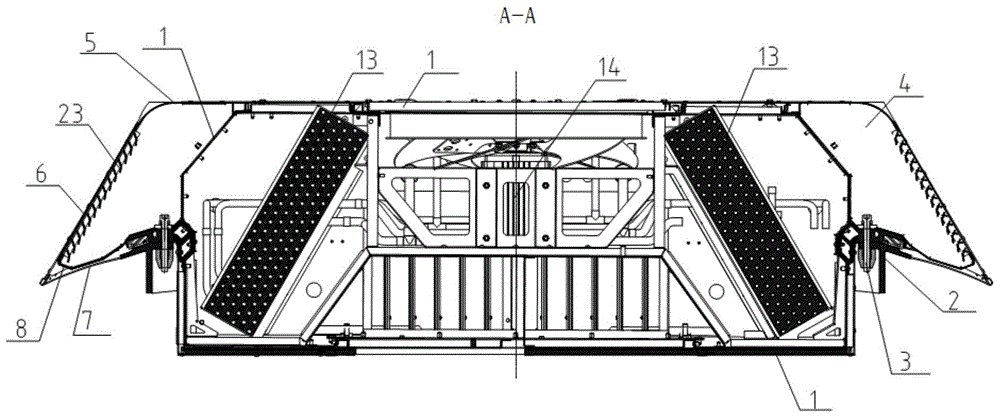

[0031] Such as Figure 1 to Figure 3 As shown, the rail vehicle roof-mounted air-conditioning unit with wind and sand protection function according to the present invention includes a shell 1, and the two sides of the shell 1 are provided with a long mounting seat 2, and the mounting seat 2 is an aluminum profile or a stainless steel structure , the mounting seat 2 is fixedly installed on the vehicle body (not shown in the figure) by the bolt 3, the lower half of the housing 1 is seated inside the vehicle body, and only the upper half is exposed outside the vehicle body.

[0032] Such as figure 1 As shown, in this embodiment, inside the housing 1, it is divided into an evaporation chamber 9, a condensation chamber 10, a fresh air chamber 11 and a waste discharge chamber 12. The evaporation chamber 9 is arranged on the left side of the condensation chamber 10, and the fresh air chamber 11 and The waste discharge chamber 12 is arranged on the right side of the condensation cham...

Embodiment 2

[0046] The difference from Embodiment 1 is that a second partition (not shown in the figure) is set between the condensing air inlet 18 and the exhaust outlet 19, and the second partition surrounds the side cover 4 on this side. The space is divided into two relatively independent condensation ventilation spaces and waste exhaust ventilation spaces. The exhaust gas in the compartment enters the waste exhaust cavity 12 through the waste exhaust inlet under the action of the exhaust exhaust fan, and then passes through the waste exhaust cavity on the housing 1. The opening enters the waste exhaust ventilation space on this side, and finally discharges out of the vehicle from the waste exhaust air outlet 19 on the side plate 6 . The air outside the vehicle only enters the condensation ventilation space from the three condensation air inlets 18 on this side, and then enters the condensation chamber 10 through the condensation chamber opening on the housing 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com