A ventable die

A technology of dies and exhaust grooves, applied in glass forming, glass blowing, glass manufacturing equipment, etc., can solve problems such as glass frit jumping, partial material, and poor glass frit blanking, so as to improve production quality and production efficiency, reducing the mating area and improving the production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

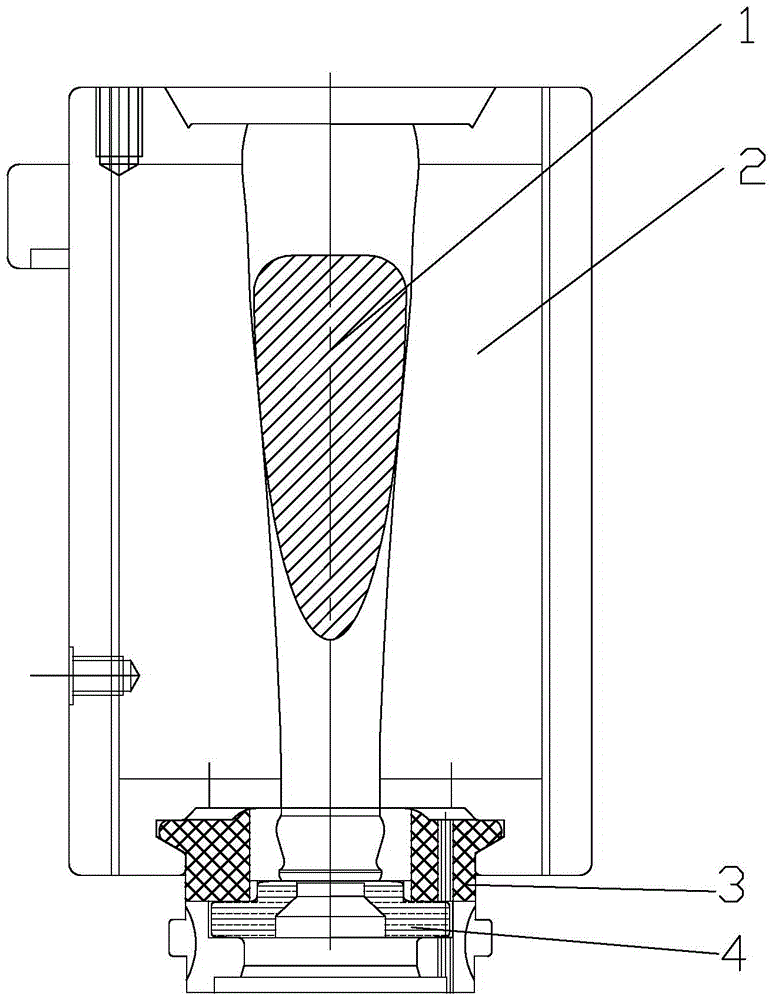

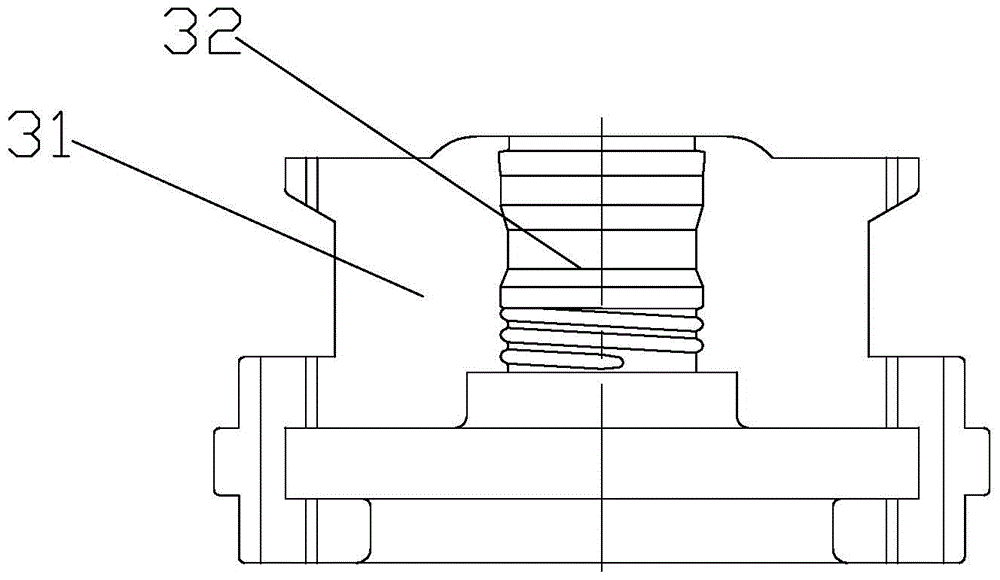

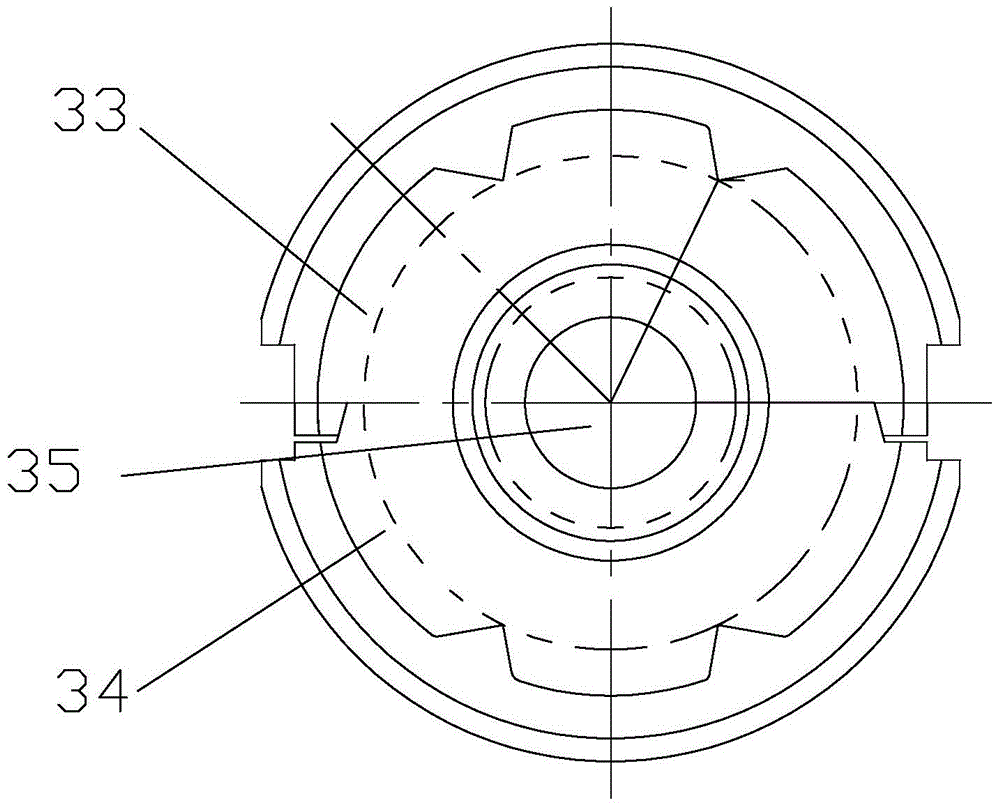

[0028] Embodiment: a kind of die that can exhaust, as image 3 , Figure 4 and Figure 5 As shown, the die 3 is made up of a male mold 33 and a female mold 34 that cooperate with each other. On the plane part 31 of the male mold 33 and the female mold 34, a cavity 32 that penetrates up and down is provided. The two cavity 32 Cooperate with each other so that a bottle cavity 35 is formed inside the entire mouth die 3. The surface that the male die 33 and the female die 34 are fitted together is called the seam surface 36, and the seam surface 36 is along the shape of the mold. The outer edges on both sides of the cavity 32 are set and protrude from the plane part 31, and each joint surface 36 is provided with a longitudinally arranged air guide groove 361, and the joint surface 36 on both sides of each air guide groove 361 There is also a laterally arranged exhaust groove A362 on the part, and the air guide groove 361 communicates with the inside of the bottle mouth 35 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com