Novel spindle device for knitter

A weaving machine and spindle technology, which is applied in the direction of braiding, textiles and papermaking, etc., can solve the problems of increased requirements for weaving machine spindles, poor wear resistance of carbon fiber, and high requirements for weaving machines, so as to avoid knitting line knuckles, avoid breakage, and increase weaving efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

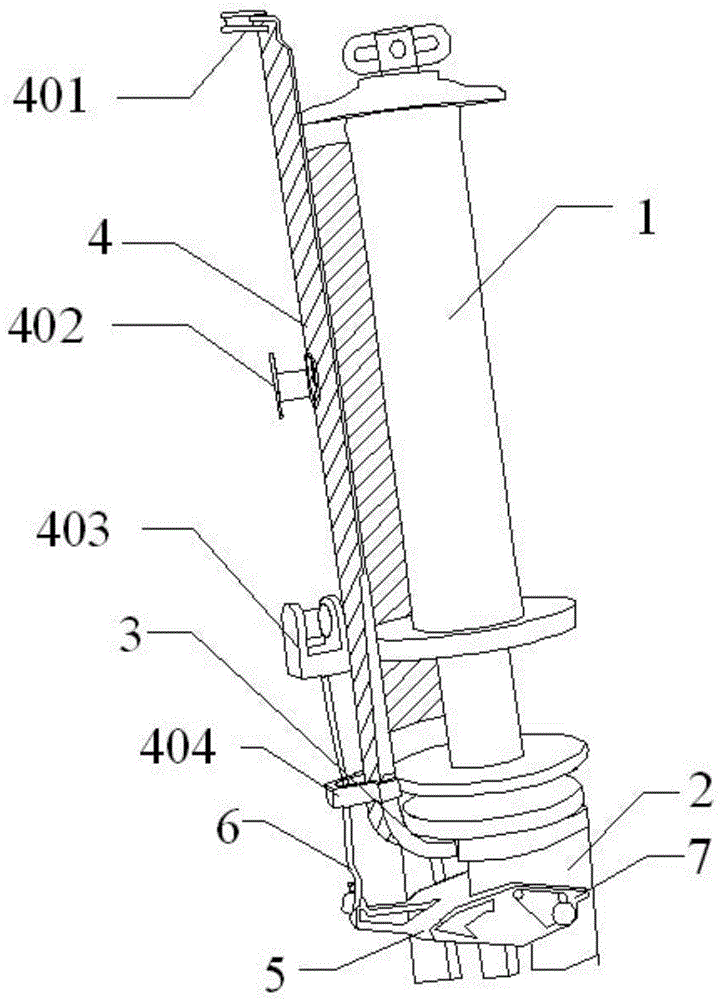

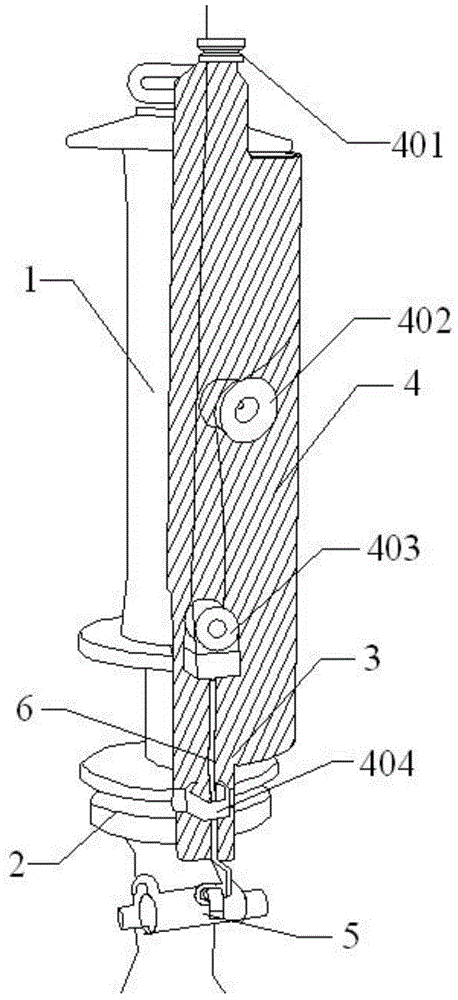

[0012] Below with reference to accompanying drawing, describe a kind of novel braiding machine spindle device of the present invention in detail.

[0013] Such as figure 1 As shown, a new type of braiding machine spindle device includes a bobbin 1, a spindle base 2 and a spindle frame 3, the bobbin 1 and the spindle frame 3 are installed on the spindle base 2, and the spindle frame 3 extends upward to form a guide plate 4 . Such as figure 2 As shown, the guide plate 4 is an arc-shaped circular plate located on the periphery of the bobbin 1, the upper end of the guide plate 4 is equipped with a vertical lead hole 401, the middle is equipped with a pulley 402, the lower end is equipped with a lead pulley 403, and the end A lead hole 404 is installed, and the vertical lead hole 401 , the pulley 402 , the lead pulley 403 and the lead hole 404 are located on the same vertical plane.

[0014] The vertical lead hole 401 and the wire passing hole 404 are titanium oxide porcelain h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com