Concave-convex friction pile

A technology of friction piles and concave-convex structures, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as limited friction, high construction costs, and low bearing capacity of single piles, and achieve enhanced friction resistance and good anti-floating , the effect of increasing the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

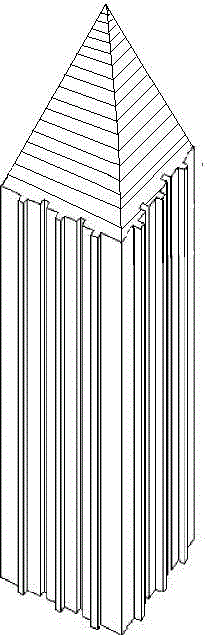

Embodiment 1

[0021] The prestressed concrete friction pile includes a pile tip and a pile body, and the surface of the pile body of the friction pile is provided with a concave-convex structure along the pile body and the pile length direction. The concave-convex structure is square, surrounded by four sides, distributed in a staggered manner, and adjacent columns are parallel. The thickness is 1 cm. Wherein, the groove depth is 10mm, and the protrusion thickness is 15mm. The friction pile is a solid pile with a square cross section.

Embodiment 2

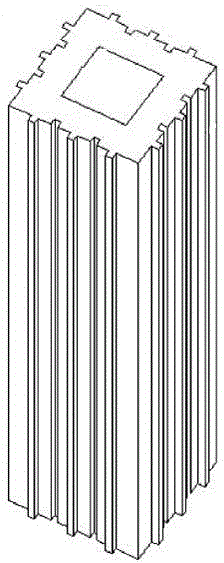

[0023] The non-prestressed concrete friction pile includes a pile body. The outer surface of the friction pile is provided with a concave-convex structure along the pile body and the length direction of the pile. The concave-convex structure is semicircular and surrounded on all sides. And the concavo-convex structure is distributed alternately, and the adjacent columns are parallel. The concave-convex structure of the friction pile has a thickness of 1.3 centimeters. The depth of the groove is 15mm, and the thickness of the protrusion is 25mm. The friction pile is a hollow pile with a rectangular cross section.

Embodiment 3

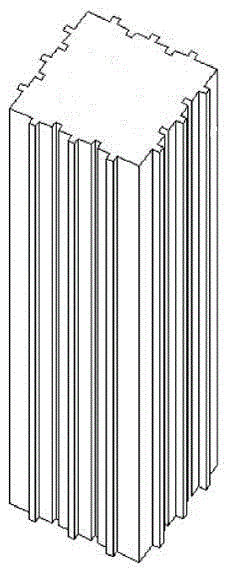

[0025] The semi-prestressed concrete friction pile includes a pile tip and a pile body. The outer surface of the friction pile is provided with a concave-convex structure along the pile body and the pile length direction. The concave-convex structure is zigzag and surrounded on all sides. And the concavo-convex structure is distributed alternately, and the adjacent columns are parallel. The concave-convex structure of the friction pile has a thickness of 0.8 cm. The depth of the groove is 15mm, and the thickness of the protrusion is 25mm. The friction pile is a hollow pile with a circular cross section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com