A widened embankment structure and construction method of high retaining wall filling section facing water suspension wall

A construction method and a technology for pavement structure, which are applied in the embankment widening project of the high retaining wall near the water cantilever, the widening of the embankment structure and construction in the filling section of the high retaining wall facing the water, and the field of the embankment structure, which can solve the complicated and cumbersome construction process. , abnormal settlement and other problems, to prevent water damage, enhance connection performance, and enhance connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The design and construction technical requirements of prestressed pipe piles in this embodiment, the technical requirements for steel bar binding and steel plate welding construction, the design and construction requirements of concrete, etc. will not be repeated in this embodiment.

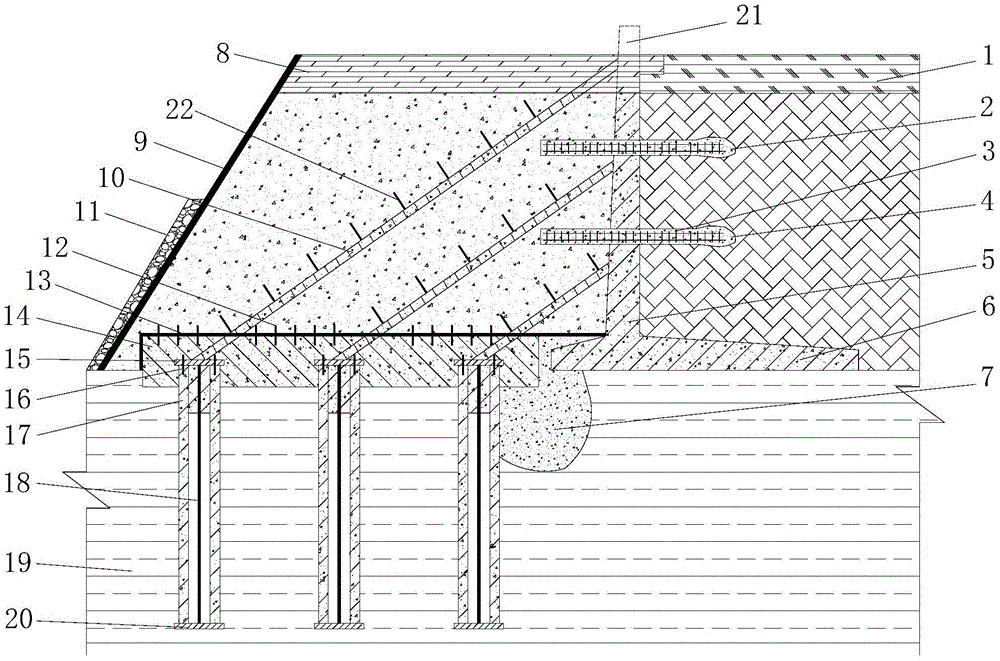

[0040] figure 1 It is a structural schematic diagram of the widened embankment structure of the high retaining wall filling section facing the water suspension wall of the present invention.

[0041] refer to figure 1 The widened embankment structure of the filling section of the high retaining wall near the water is mainly composed of the original pavement structure 1, the horizontal connecting steel cage 3, the grouting reinforcement 7, the newly widened part of the pavement structure 8, the oblique support 10, and the mortar masonry It consists of flake slope protection 11, reinforced concrete continuous slab 14, prestressed pipe pile 17, and original soil body 19.

[0042]The top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com