Pump-type feedback energy crosslinking suspension system

A cross-linked suspension system and energy-feeding technology, applied in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as heat energy waste, achieve efficient recovery, improve handling stability and ride comfort , the effect of improving fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings.

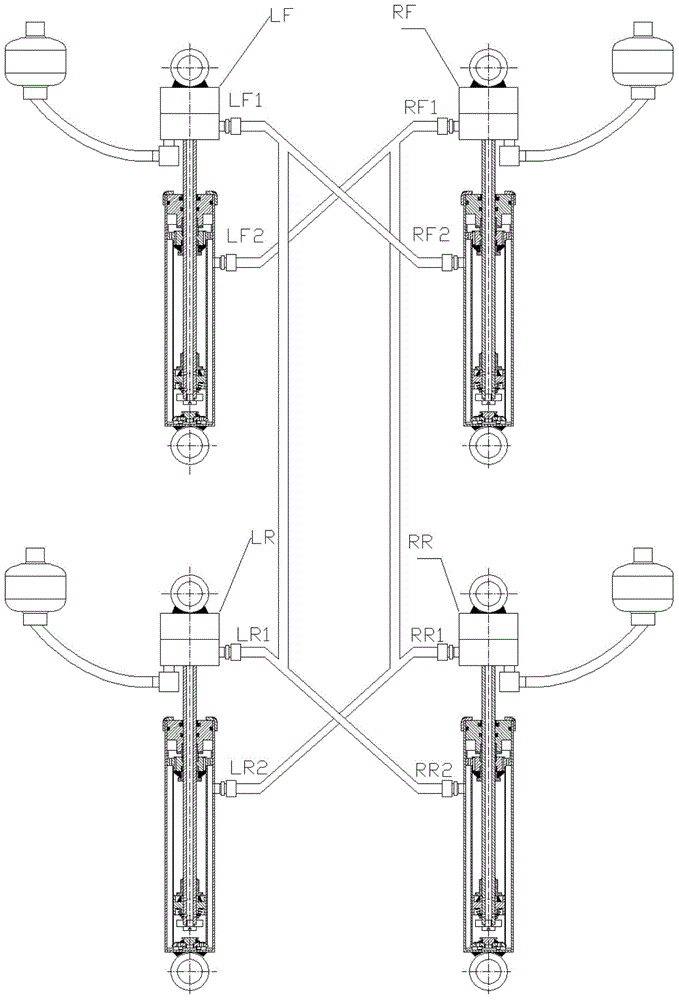

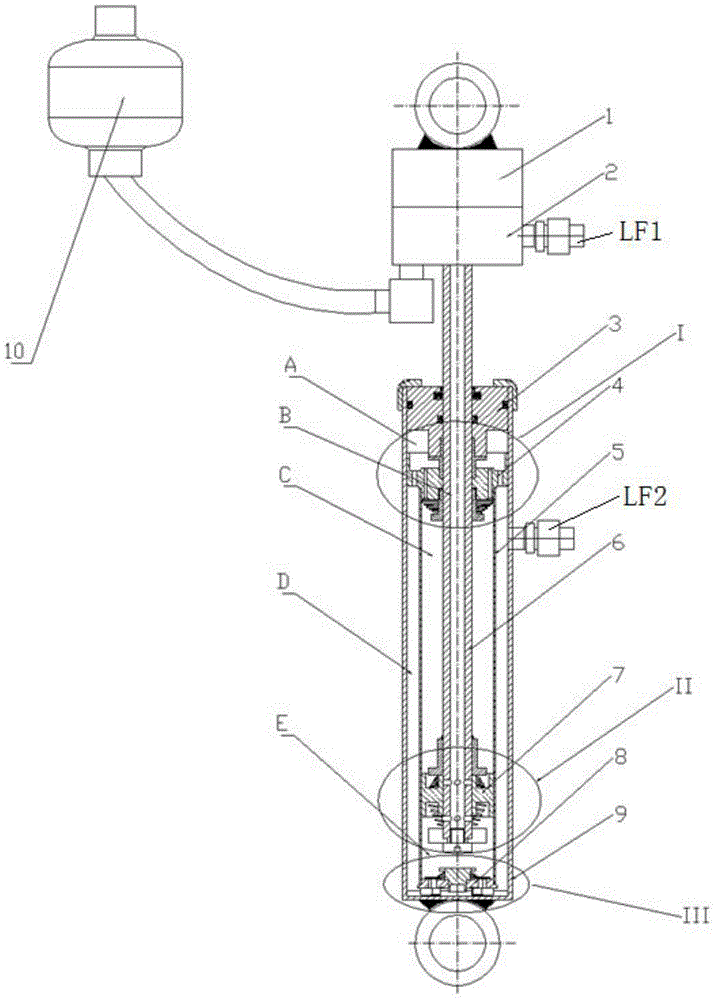

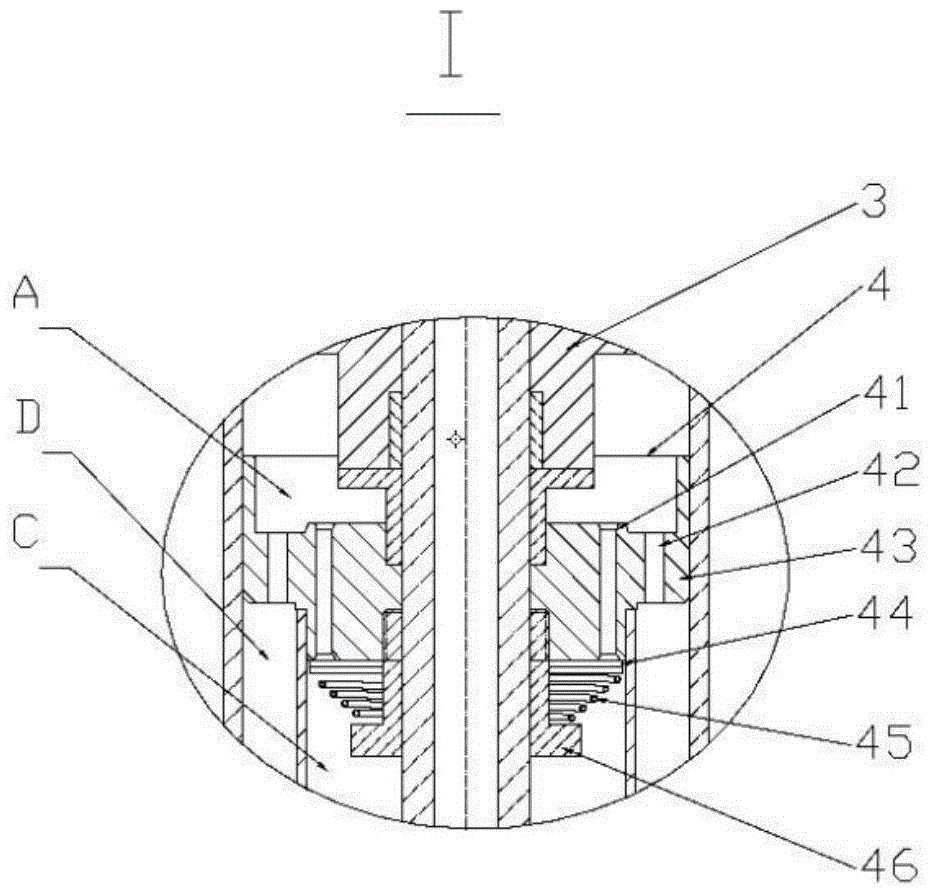

[0055] figure 1 It is an embodiment of the present invention, and its cross-linking mode is "left and right cross-linking, front and rear communication", mainly including left front pump type energy feed shock absorber LF, right front pump type energy feed shock absorber RF, left rear pump type energy feed shock absorber The energy-feeding shock absorber LR and the right rear pump-type energy-feeding shock absorber RR; the structure of the four pump-type energy-feeding shock absorbers is the same, and all have hydraulic power generation modules. flow in the opposite direction, and then drive the hydraulic power generation module to generate electricity; among them, the oil outlet LF1 of the left front pump energy-feeding shock absorber, the oil inlet RF2 of the right front pump energy-feeding shock absorber, and the oil outlet of the left rear pump energy-feeding Po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com