How to make an air storage bag

A manufacturing method and a technology of an air storage bag, which are applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, building components, etc., can solve problems such as the inability to fully utilize carbon dioxide, and achieve the purpose of suppressing the spread, expansion, and enhancement of fires High elasticity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 A kind of air storage bag

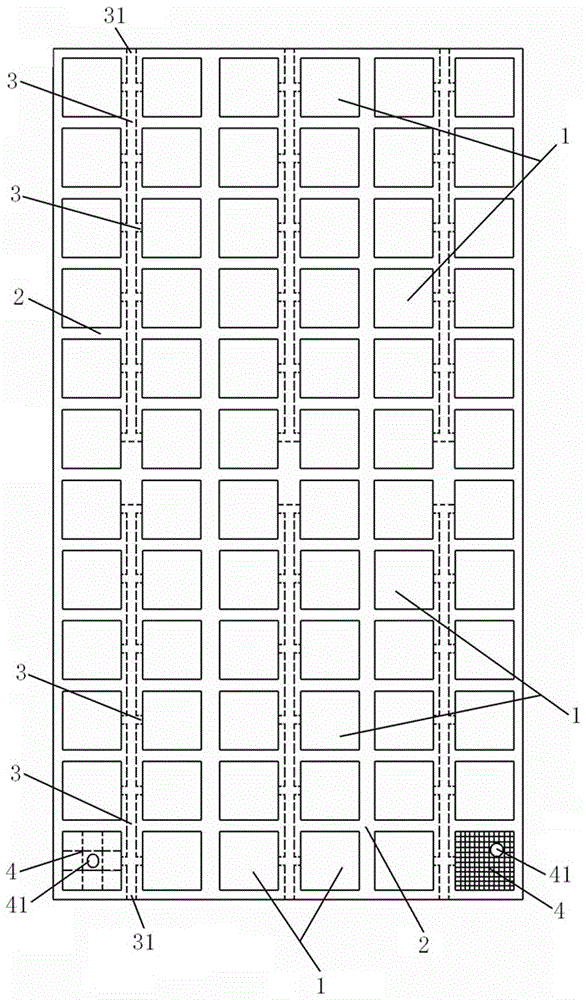

[0037] Such as figure 1 As shown, the gas storage bag in this embodiment is mainly composed of a plurality of gas storage bag cavities 1 filled with carbon dioxide gas and a sealed plastic layer 2, and the sealed plastic layer 2 is provided with The inflatable passages 3 in which the bag cavities 1 communicate with each other, and the inside of the air storage bag cavity 1 is provided with a tensile fiber layer 4 that prevents the air storage bag cavity 1 from expanding to the surroundings when it is under pressure. Preferably, the tensile fiber layer 4 is provided with ventilation holes 41 to enhance the gas flow performance in the gas storage bag cavity 1 . The air storage bag cavity 1 and the sealing plastic layer 2 can be made of thermoplastic EPDM dynamic vulcanized rubber, which has good elasticity, resistance to compression deformation, environment resistance and aging resistance. Preferably, the tensile fiber layer 4 an...

Embodiment 2

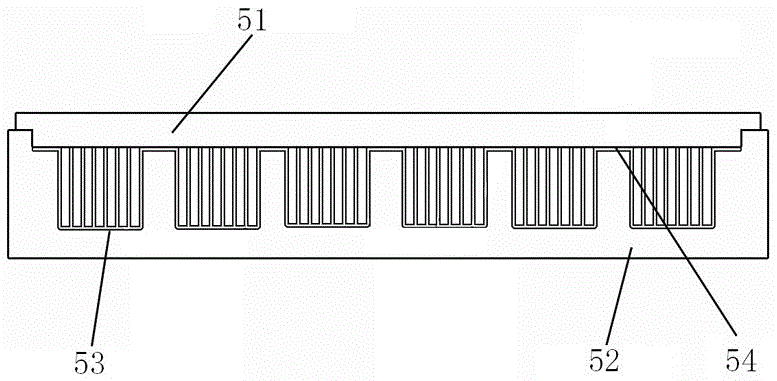

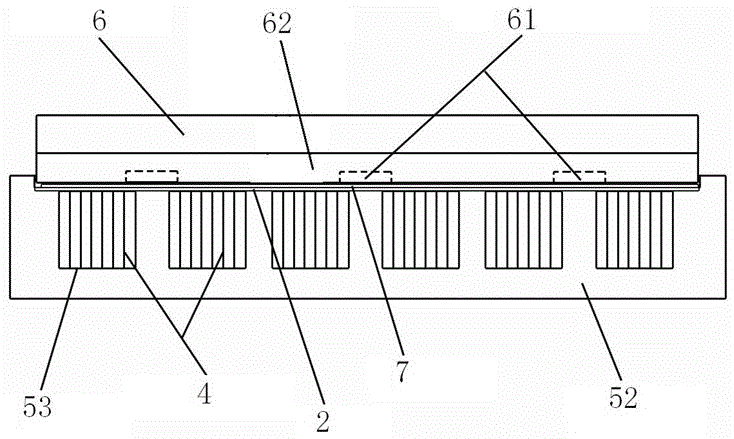

[0038] Embodiment 2 A production line for making air storage bags

[0039] Such as Figures 2 to 4As shown, the air storage bag production line described in this embodiment includes a mold for mass production of the air storage bag cavity 1 and a fusion member 6 for fusing the air storage bag cavity 1 and the sealing plastic layer 2, specifically, The mold is mainly composed of a casting master plate 51 and a mold master plate 52. Inside the mold master plate 52, a plurality of mold cavities 53 corresponding to the shape of the air storage bag cavity 1 are arranged in double rows. Heat insulating lines are arranged on the working surface of the fusion part. Specifically, a heating plate 62 is provided below the fusion member 6, and a plurality of interconnected heat insulating lines 61 are provided on the working surface of the heating plate 62, and each heat insulating line 61 extends to the mold one by one. The edge of the mold cavity is used to cooperate with the double-r...

Embodiment 3

[0040] Embodiment 3 A kind of manufacturing method of air storage bag

[0041] The manufacturing method of the air storage bag in the present embodiment comprises the following steps:

[0042] S1) Making bag embryos: put the die casting of the mold master plate 51 into the mold cavity 53 of the mold master plate 52, the die cast is composed of a plurality of sheet-like high-temperature resistant objects with gaps left between each other, and the die cast After the periphery of the master plate 51 and the mold master plate 52 are tightly sealed, the prepared plastic slurry is injected into the injection seam in the mold through the injection hole, and the mold casting seam and the surrounding injection seams are formed to cross each other after the injected plastic paste is solidified. The plastic tensile fiber layer 4 is integrated with the bag wall at the periphery and the bottom, and the plastic slurry is solidified to form a Figure 5 The pocket embryo shown in.

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com