Double-flow-state clean combustion boiler and double-flow-state clean combustion technology

A clean combustion and fluid state technology, applied in the direction of fuel burning in molten state, fluidized bed combustion equipment, combustion method, etc., can solve the problems of large difference in fluidization wind speed, difficult theoretical requirements, and increase in the amount of fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

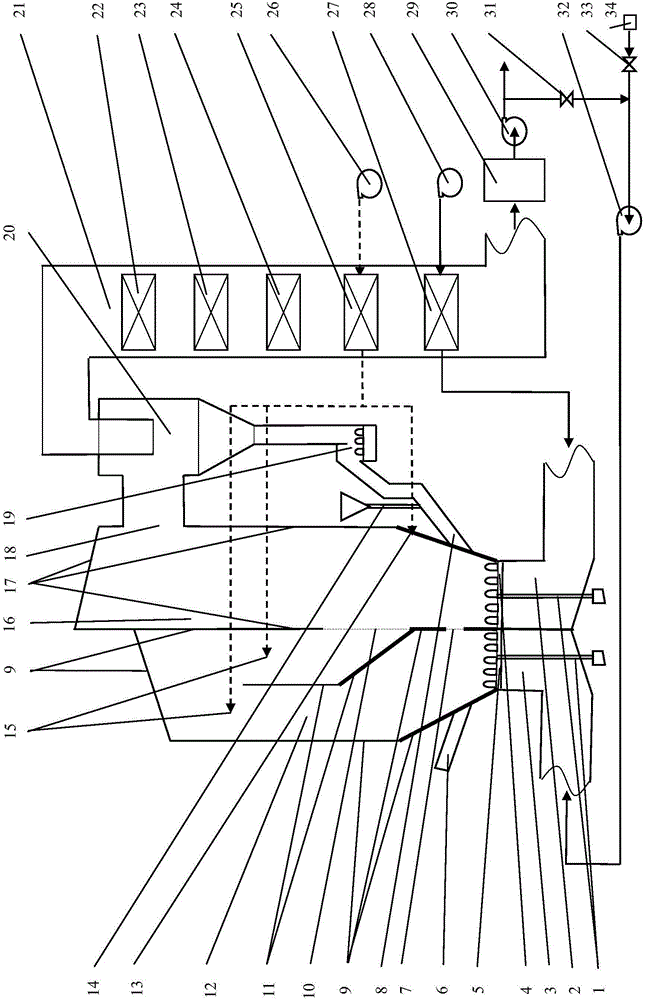

Examples

Embodiment 2

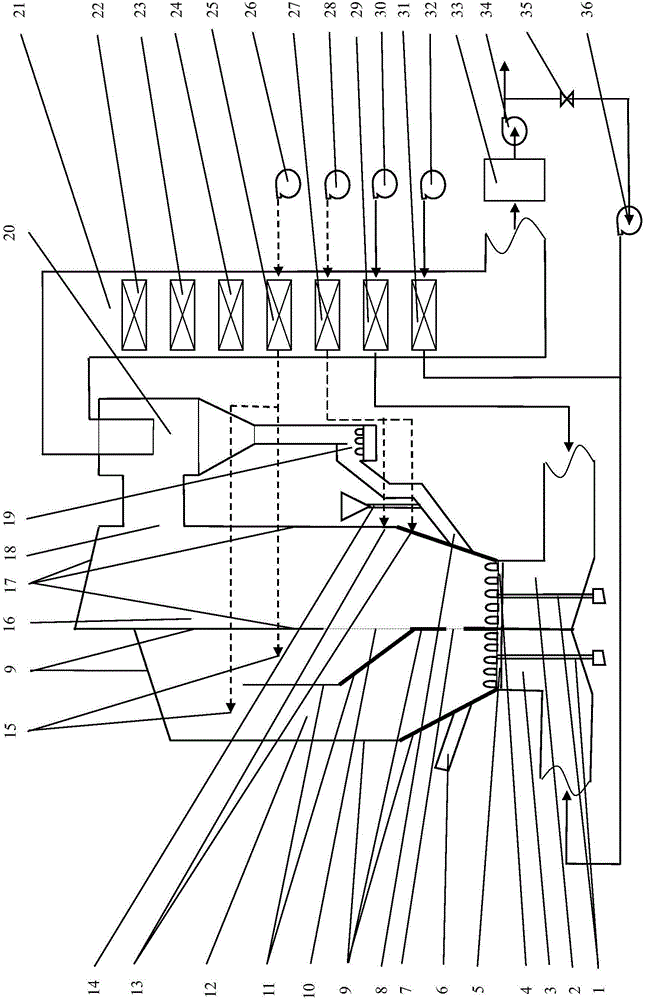

[0065] Embodiment two, such as figure 2 Shown:

[0066] The specific structure and composition of the bubbling bed and the circulating bed are basically the same as those in Example 1, the difference is that the source of the primary air, optionally, the bubbling fluidized bed (bubbling bed for short) is respectively provided with a second A primary air flue gas fan 36 and a second primary air fan 32, and a second primary air air preheater 31 is arranged at the outlet air duct of the second primary air fan 32. The flue gas volume, air volume and primary air volume of the bubbling bed are adjusted by fan speed regulation.

[0067] Similarly, the bubbling bed secondary air can be separately provided with a bubbling bed secondary fan 26 or / and a bubbling bed secondary air air preheater 25 .

[0068] Likewise, in the bubbling bed furnace, the secondary tuyeres 15 of the bubbling bed furnace can be arranged in multiple layers or / and in multiple points. The style of the tuyere c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com