A kind of method for producing nicotinamide by continuous hydrolysis of 3-cyanopyridine

A cyanopyridine hydrolyzate and cyanopyridine technology, applied in organic chemistry and other fields, can solve problems such as hidden dangers in production safety, difficult control, and large environmental pollution, and achieve the effect of ensuring product quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

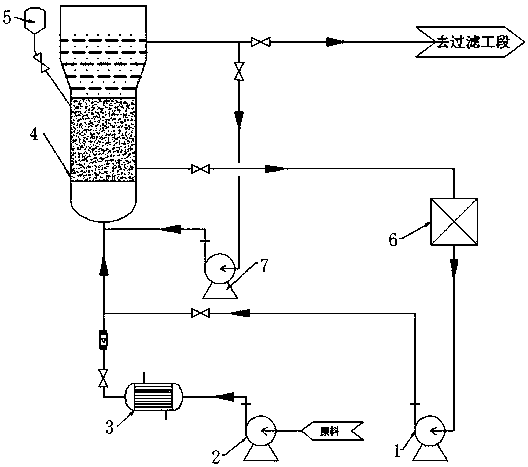

Image

Examples

Embodiment 1

[0028] The mixed solution with a mass concentration of 3-cyanopyridine of 26% was heated to 107°C by a pump through a heat exchanger and then entered into a fluidized bed reactor at a feed rate of 2.5 L / S. First, turn on the pump 7 to carry out external circulation for about 1.5 hours. The nicotinamide content in the reactor is about 0.837mol / L. At this time, open the outlet valve and adjust the two valves of the outlet and the circulation to control the circulation ratio to 1:4. Under stable operating conditions, the content of nicotinamide measured by sampling is about 0.82, and the conversion rate of 3-cyanopyridine is about 91%. The service life of the catalyst is about 50 hours. After 30 hours of reaction, the catalyst filtration and discharge and filtrate return circuit are opened for about 5 minutes every hour, and 60kg of catalyst is added by using the catalyst filling part.

Embodiment 2

[0030] The mixed solution with a mass concentration of 3-cyanopyridine of 26% was heated to 107°C by a pump through a heat exchanger and then entered into a fluidized bed reactor at a feed rate of 2.5 L / S. First, turn on the pump seven to carry out external circulation for about 1.5 hours, and the nicotinamide content in the reactor is about 0.89mol / L. At this time, open the outlet valve and adjust the two valves of the outlet and the circulation to control the circulation ratio to 8:25. Under stable operating conditions, the content of nicotinamide measured by sampling is about 0.86, and the conversion rate of 3-cyanopyridine is about 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com