Debugging Method of Electronic Controller Parameters for Engineering Machinery

An electronic controller and parameter debugging technology, applied in the direction of electrical testing/monitoring, etc., can solve the problems of error-prone parameter value modification and unintuitive parameter modification methods, etc., and achieve the effect of intuitive parameter expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

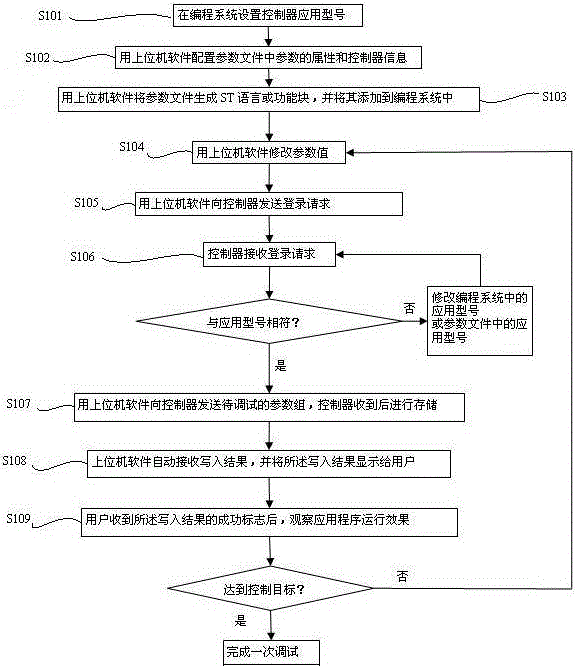

[0036] Below in conjunction with accompanying drawing example, the present invention is described in further detail:

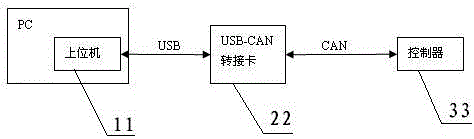

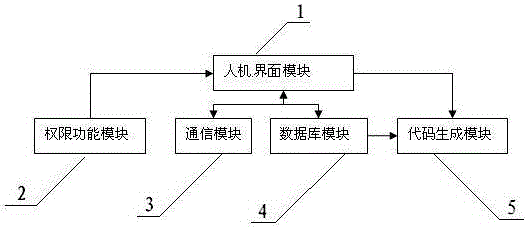

[0037] like figure 1 and figure 2 In the present embodiment shown, the controller 33 is connected to the host computer 11 through the adapter card 22, and the parameter debugging method of the controller 1 includes the following steps:

[0038] S101: The user sets the controller application model in the programming system of the controller, and the application model includes that the operating system provides relevant functional functions and calls the functional functions in the programming system to set the controller application model;

[0039] S102: The user uses the upper computer software to configure a parameter file, which includes controller information and a parameter group, and the parameter group includes parameter name, maximum value, minimum value, step value, default value, offset, resolution, Units and permissions, the permissions include de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com