Crystal grape slope TU shape pruning technology

A technology of plastic pruning and sloping land, applied in the fields of application, cultivation, agriculture, etc., can solve the problems of increasing the density of planting spacing in horizontal ladder belts, unfavorable grape industrialization management, unfavorable grape fruiting growth, etc., to promote robust growth and yield Extremely easy to control and avoid overlapping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

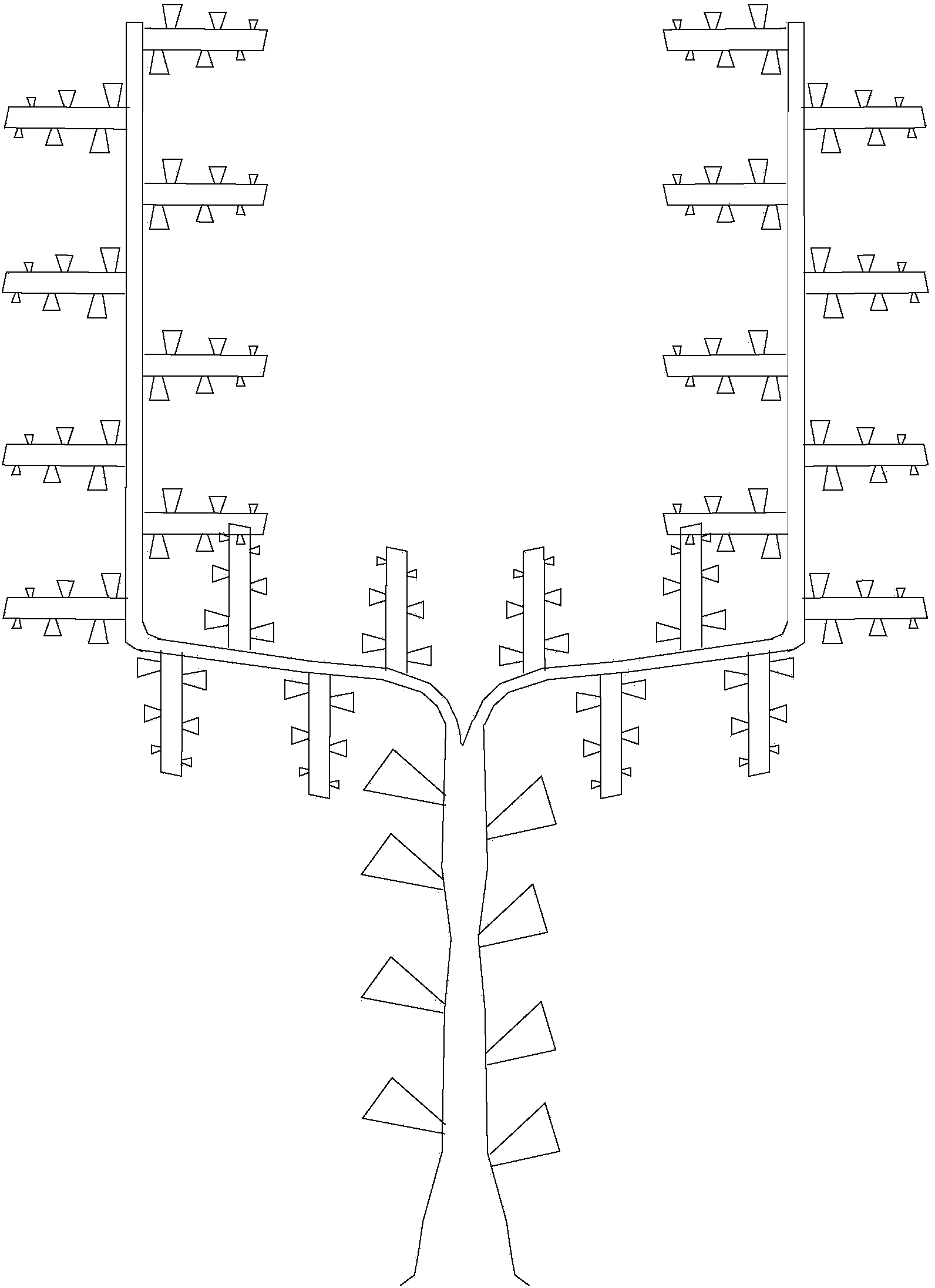

[0023] A TU-shape shaping and pruning technique for crystal grape slopes, as attached Figure 1-2 As shown, this pruning technique cuts short the seedlings of the fixed value year, selects two new shoots after germination, selects one strong branch as the main vine, and inserts the pole to stretch and spread it on the shelf, and the other weak branch is erased. After the main vine grows, pinch the core to form the main trunk. After pinching, cultivate two auxiliary shoots at the upper two nodes as the main branch, erase the other auxiliary shoots, and remove the tendrils of the grapes. The two main branches first grow along the horizontal direction of the slope. A T-shaped structure is formed between the main branches and the main trunk, and then each vertical slope is guided upward along the slope, bound and cultivated, and then topped. At this time, a U-shaped structure is formed between the two main branches, and the leaf axils of each main branch grow out. The second-level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com