Tendon transmission artificial hand

A prosthetic hand and transmission wheel technology, applied in the field of tendon transmission prosthetic hand, can solve the problems of poor practicability and inability to achieve force grasping, etc., and achieve the effects of strong practicability, low processing cost and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

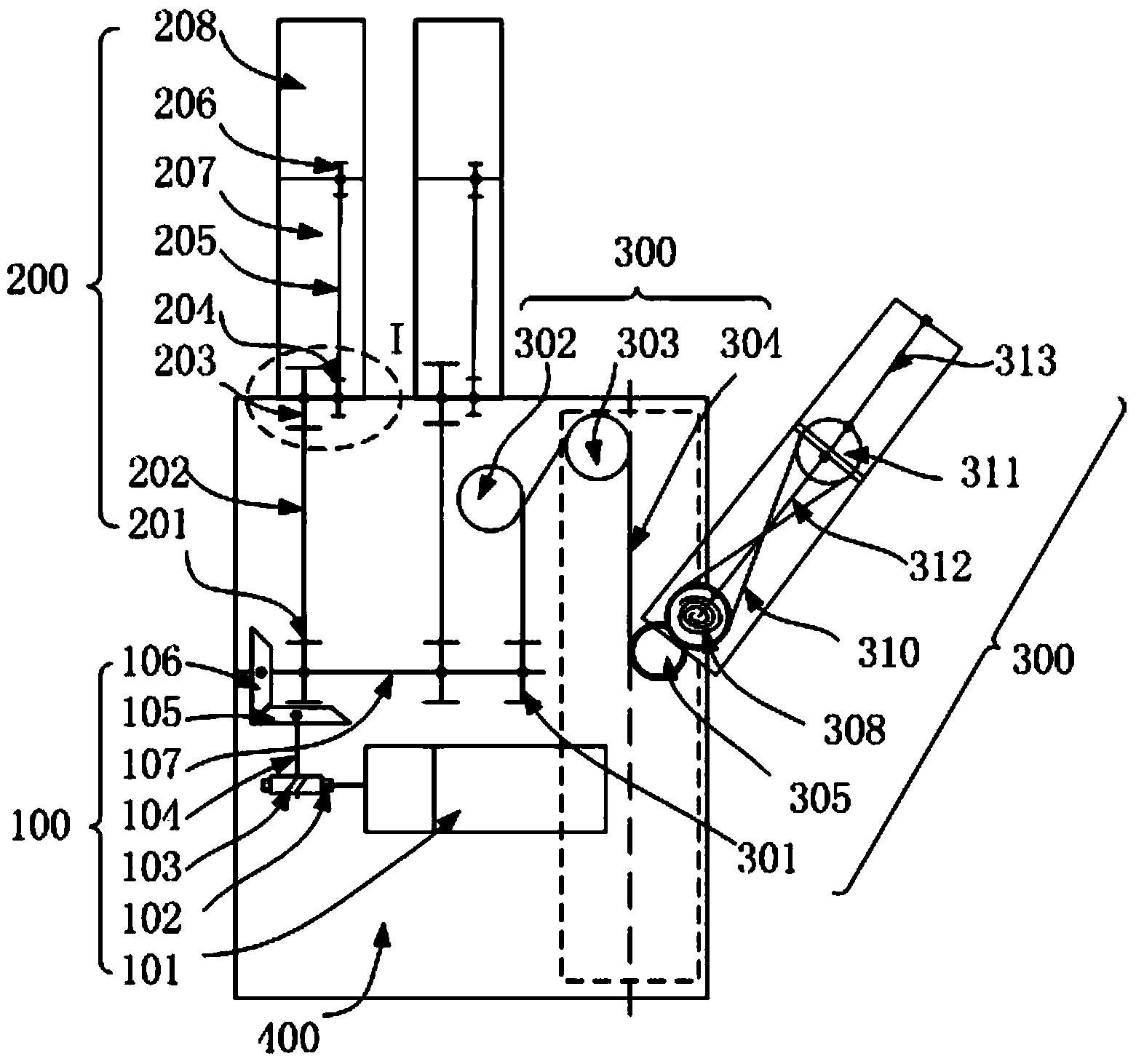

[0047] refer to figure 1 , the present embodiment provides a tendon-driven prosthetic hand, including a driving part 100 , a finger driving part 200 , a thumb driving part 300 and a palm cavity 400 , and the driving part 100 is installed in the palm cavity 400 .

[0048] The driving part 100 includes a gear motor 101 equipped with a drive shaft, a transmission mechanism and a total drive shaft 107 , one end of the transmission mechanism is connected to the drive shaft of the gear motor 101 , and the other end is connected to the total drive shaft 107 .

[0049] The geared motor 101 is arranged laterally in the palm cavity 400, and the geared motor 101 is an improved motor integrated with a motor and a reducer, in order to make the overall structure of the tendon-driven prosthetic hand more compact. In the geared motor 101, the motor is a DC brushless servo motor, and the reducer is a harmonic reducer.

[0050] This transmission mechanism comprises worm gear 102, worm screw 10...

Embodiment 2

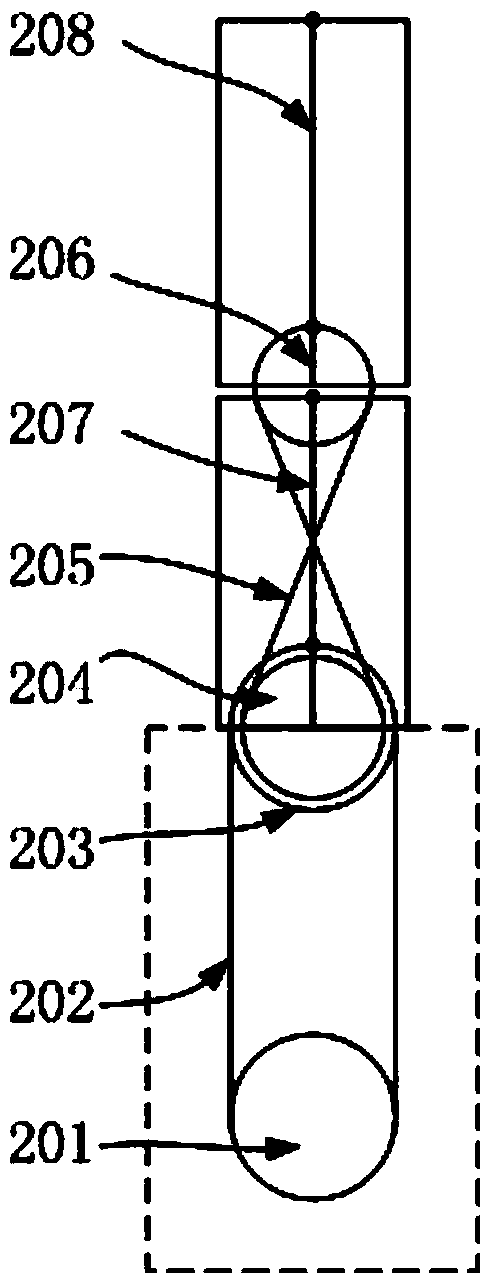

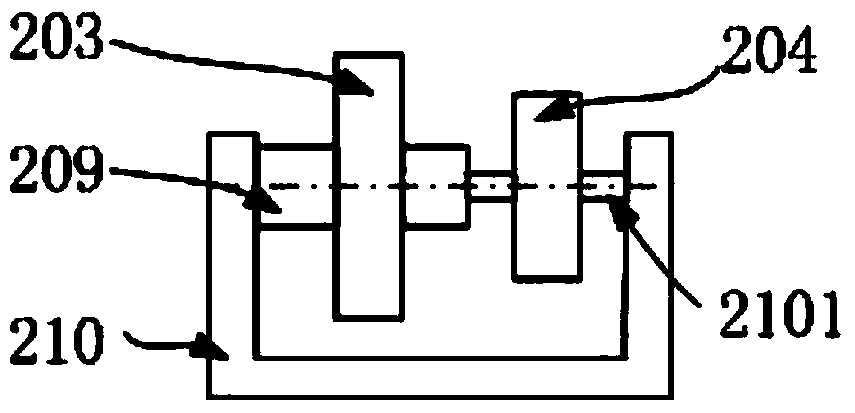

[0078] refer to figure 1 and Figure 7 The only difference between this embodiment and Embodiment 1 is that in this embodiment, the finger transmission part also includes a third finger transmission mechanism, a third finger knuckle 214 and a third finger joint shaft, and the third finger transmission mechanism includes a third finger transmission mechanism. Five finger transmission wheel 211, the sixth finger transmission wheel 213 and the third finger transmission tendon 212.

[0079] The fifth finger transmission wheel 211 is fixed on the second finger joint shaft and rotates coaxially with the fourth finger transmission wheel 206. The third finger transmission tendon 212 is a cross tendon rope, and the fifth finger transmission wheel 211 passes through the The third finger transmission tendon 212 transmits to the sixth finger transmission wheel 213, the sixth finger transmission wheel 213 is fixed on the third finger joint shaft, and the third finger joint shaft is instal...

Embodiment 3

[0082] The difference between this embodiment and Embodiment 1 is that the geared motor in this embodiment is arranged vertically, and the transmission mechanism of the driving part does not include the first bevel gear and the second bevel gear. Specifically, the transmission mechanism includes a worm gear and a worm screw, the drive shaft of the geared motor is connected to the worm screw, the worm screw meshes with the worm gear, and the worm gear is connected to the main drive shaft.

[0083] When the deceleration motor works, it drives the worm to move, and the worm is meshed with the worm gear, and then the worm gear is transmitted to the main drive shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com