Multifunctional cutting insert and tool

A multi-functional blade technology, applied in the direction of milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problem that cutting blades cannot be used universally, and achieve good chip breaking performance, good surface quality, and high processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

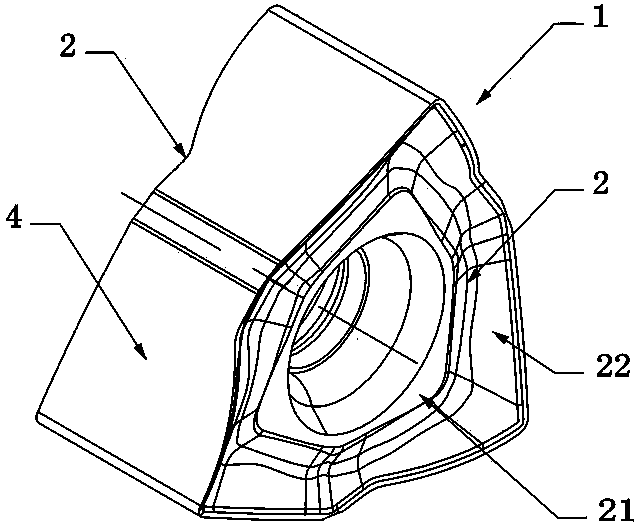

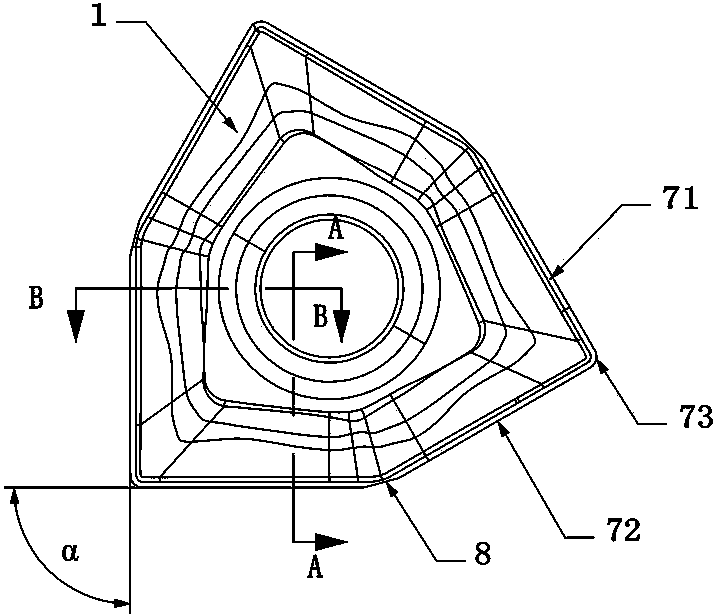

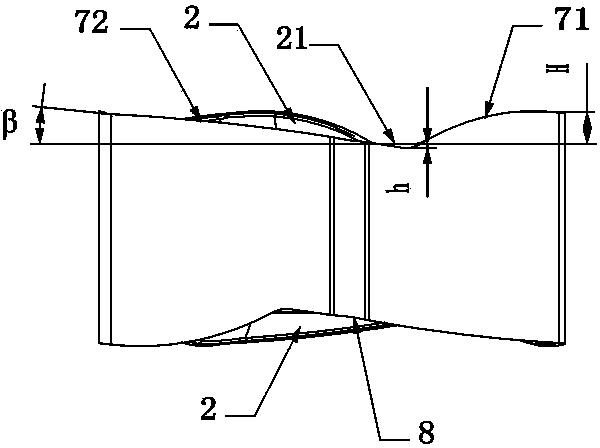

[0031] Figure 1 to Figure 5 Shown is a kind of multifunctional milling insert embodiment of the present invention, and this milling insert comprises by upper and lower surface 2 and three sides 4 that connect upper and lower surface 2 and surrounds triangular plate shape insert body 1, upper surface and lower surface The surface structure is the same, the upper and lower surfaces 2 are composed of a plane 21 and a rake face 22, and the three side faces 4 intersect with each rake face 22 to form three pairs of cutting edge groups 7 evenly distributed on the edge of the blade body 1. The cutting edge groups 7 consists of a main cutting edge 71, a minor cutting edge 72, and a corner cutting edge 73 connecting the main cutting edge 71 and the minor cutting edge 72. A group of major cutting edges 71 in a pair of cutting edge groups 7 on the upper and lower surfaces 2 , minor cutting edge 72 and another group of minor cutting edge 72, major cutting edge 71 correspond respectively, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com